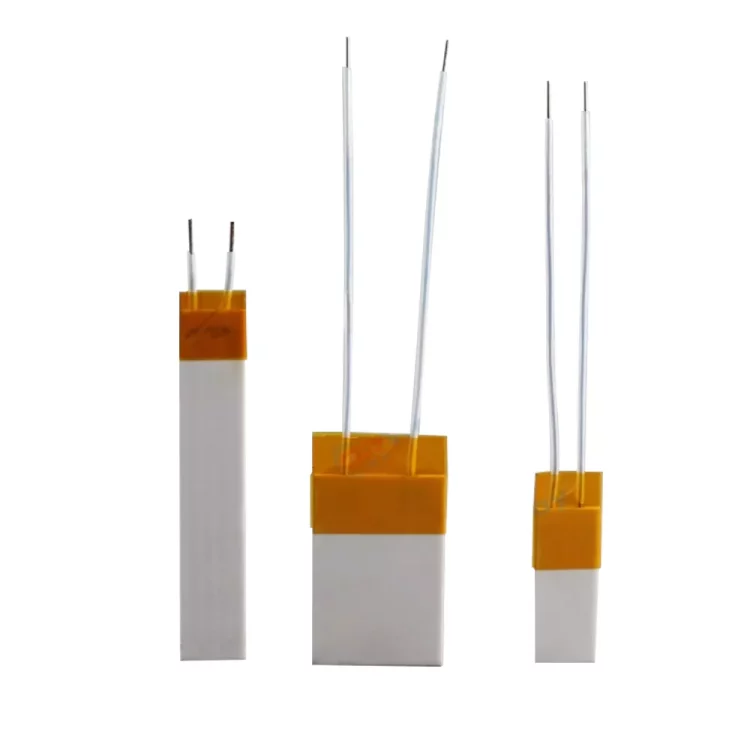

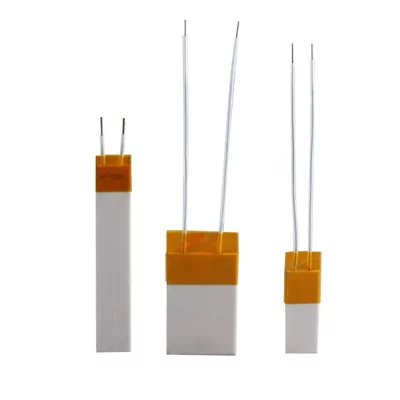

GORGEOUS CERAMICS (GGS) alumina ceramic heating plates for hair straighteners are manufactured using ceramic lamination technology, resulting in an alumina content of up to 95%.

Alumina ceramic heating plates have a wide range of applications, primarily in automotive systems and industrial equipment, including soldering irons, kerosene and gas equipment, pellet burners, and water heaters.

MCH alumina ceramic heating elements are a new type of heating element created by directly printing circuits onto alumina green sheets. These elements undergo a series of specialized processes and are then co-fired at a high temperature of approximately 1600°C.

Our product can reach a temperature of 800°C in just 30 seconds, achieving rapid heating. Furthermore, it operates silently and contains no harmful substances, making it a new type of environmentally friendly heating element.

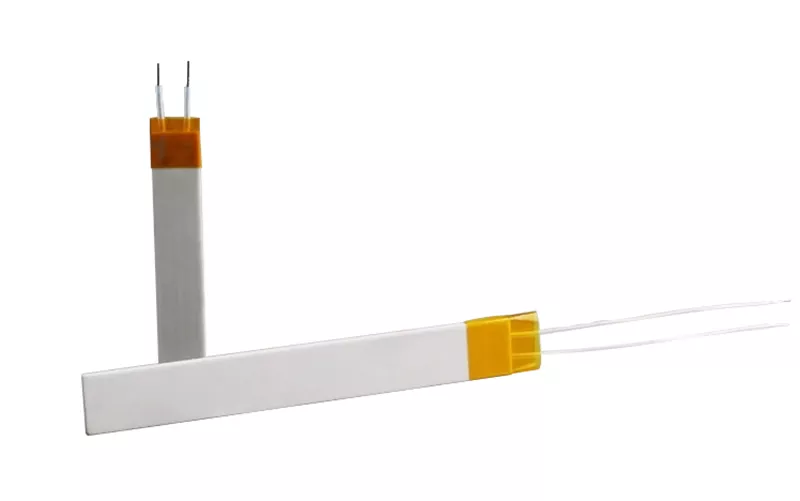

Alumina Ceramic Heating Element for Hair Straighteners Product Information

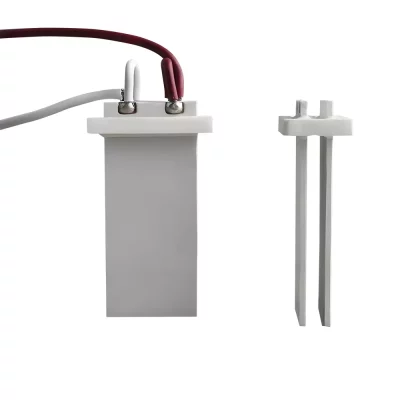

- Base material: White multi-layer alumina ceramic with an Al2O3 content of at least 95%.

- Lead: Measured in mm². 5mm nickel wire.

- Casing and tape: Teflon, high-temperature resistant.

- Resistors: Tungsten or other high-temperature materials.

- Thickness: 0.7-2.0 mm. Customizable.

- Operating voltage: 3.7V, 4.5V, 5V, 7V, 6V, 9V, 12V, 24V, 36V, 110V, 220V, 380V, customizable.

- Resistance options: 0.3-1500 ohms, depending on voltage, chip size, power, and customer requirements.

Product Specifications Reference

The surface temperature of the ceramic heating element can reach 200°C in seconds, 500°C in 30 seconds, and a maximum stable temperature of 600-800°C, depending on the heat sink.

The ceramic heater has passed 1000 cycle tests at approximately 280°C, with a 60-minute “on” and 60-minute “off” cycle.

With its compact size, high power density, high-temperature resistance, and excellent insulation properties, it is ideal for scientific research in laboratory environments.

The following are GORGEOUS CERAMICS (GGS) currently available models for you to choose from. If you don’t have the model you need, we can provide custom designs!

Specification

|

Specification |

Models |

Length (mm) |

Width (mm) |

Thickness (mm) |

Leads (mm) |

фleads (mm) |

|

|

10*10*1.3(2.0) |

24/12VAC |

9Ω |

10 |

10 |

1.3 |

75 |

0.5 |

|

|

24/12VAC |

13Ω |

10 |

10 |

1.3 |

75 |

0.5 |

|

20*10*1.3(2.0) |

24/12VAC |

10Ω |

20 |

10 |

1.3 |

75 |

0.5 |

|

|

|

15Ω |

20 |

10 |

1.3 |

75 |

0.5 |

|

|

|

20Ω |

20 |

10 |

1.3 |

75 |

0.5 |

|

30*25*1.3(2.0) |

24VAC |

20Ω |

30 |

25 |

1.3 |

75 |

0.5 |

|

|

|

25Ω |

30 |

25 |

1.3 |

75 |

0.5 |

|

|

|

30Ω |

30 |

25 |

1.3 |

75 |

0.5 |

|

|

|

35Ω |

30 |

25 |

1.3 |

75 |

0.5 |

|

55*10*1.3(2.0) |

3.7VAC |

0.3Ω |

55 |

10 |

1.3 |

75 |

0.5 |

|

|

|

0.35Ω |

55 |

10 |

1.3 |

75 |

0.5 |

|

|

|

0.4Ω |

55 |

10 |

1.3 |

75 |

0.5 |

|

|

|

0.5Ω |

55 |

10 |

1.3 |

75 |

0.5 |

|

70*10*1.3(2.0) |

220VAC |

180Ω |

70 |

7 |

1.3 |

75 |

0.5 |

|

|

|

150Ω |

70 |

7 |

1.3 |

75 |

0.5 |

|

|

|

140Ω |

70 |

7 |

1.3 |

75 |

0.5 |

|

|

|

120Ω |

70 |

7 |

1.3 |

75 |

0.5 |

|

|

110VAC |

110Ω |

70 |

7 |

1.3 |

75 |

0.5 |

|

|

|

80Ω |

70 |

7 |

1.3 |

75 |

0.5 |

|

|

|

60Ω |

70 |

7 |

1.3 |

75 |

0.5 |

|

|

|

40Ω |

70 |

7 |

1.3 |

75 |

0.5 |

|

70*10*1.3(2.0) |

220VAC |

180Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

|

150Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

|

140Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

|

120Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

|

110Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

110VAC |

80Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

|

60Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

|

40Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

3VAC |

2Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

12VAC |

6Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

|

|

10Ω |

70 |

10 |

1.3 |

75 |

0.5 |

|

70*15*1.3(2.0) |

220VAC |

180Ω |

70 |

15 |

1.3 |

75 |

0.5 |

|

|

|

150Ω |

70 |

15 |

1.3 |

75 |

0.5 |

|

|

|

140Ω |

70 |

15 |

1.3 |

75 |

0.5 |

|

|

|

120Ω |

70 |

15 |

1.3 |

75 |

0.5 |

|

|

|

110Ω |

70 |

15 |

1.3 |

75 |

0.5 |

|

|

110VAC |

80Ω |

70 |

15 |

1.3 |

75 |

0.5 |

|

|

|

60Ω |

70 |

15 |

1.3 |

75 |

0.5 |

|

|

12VAC |

3Ω |

70 |

15 |

1.3 |

75 |

0.5 |

|

70*20*1.3 |

220VAC |

180Ω |

70 |

20 |

1.3 |

75 |

0.5 |

|

|

|

150Ω |

70 |

20 |

1.3 |

75 |

0.5 |

|

|

110VAC |

60Ω |

70 |

20 |

1.3 |

75 |

0.5 |

|

|

|

40Ω |

70 |

20 |

1.3 |

75 |

0.5 |