Advantages of Ceramic Heating Elements for Instant Water Heating

- Fast heat-up

- Electrical insulation

- Miniature/high power

- Excellent thermal performance

- Customizable temperature profile

- High insulation allows for direct contact with water, kerosene, and metal

- High reliability

- Excellent dielectric strength and electrical insulation

- Resistivity material, oxidation-resistant design, for extended service life

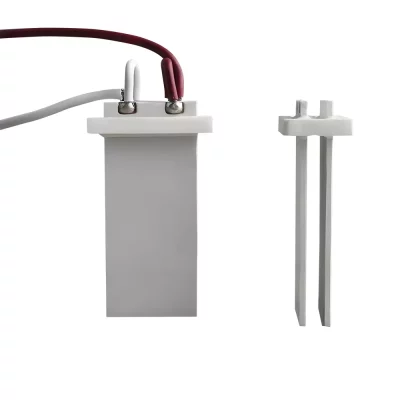

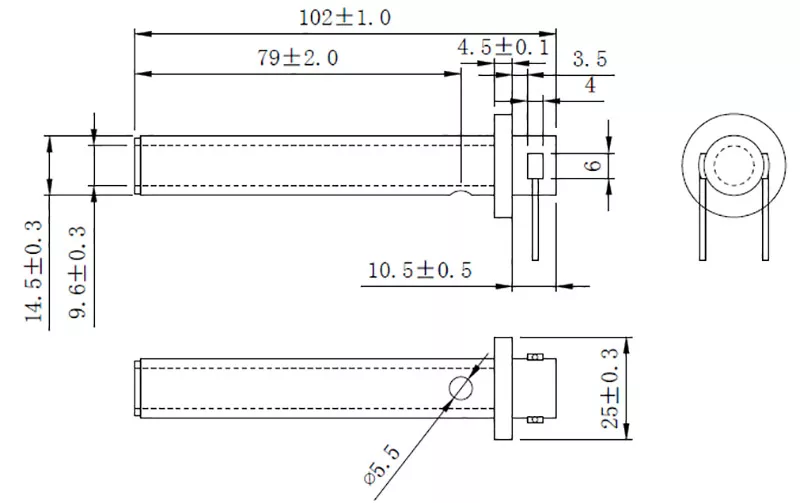

Ceramic Water Heater Element Details Structure Diagram

- Operating Voltage: 220V

- Heating Power: 3000W+/-

- Length * Outer Diameter * Inner Diameter: 102mm * 14.5mm * 9.6mm

- Ceramic Flange: Round

- Cable: Our open-type model or equivalent

Electrical Performance of Instant Ceramic Water Heater Elements

|

Test items |

Test environment |

Standard |

Test conditions and methods |

|

Resistance value |

Temperature 23℃±2℃ |

11-12.5Ω |

Then heat at 23℃±2℃for 0.5h. |

|

Test |

When electricity is supplied to the water, the outlet water temperature is 40±5℃ |

No damage to heater |

In water @AC220V 1 minute |

|

Power |

When electricity is supplied to the water, the outlet water temperature is 40±5℃ |

2800-3100W |

In water @AC220V |

|

Dielectric strength |

Temperature 23℃±3℃ |

The heater has no faults and the leakage current does not exceed 2mA. |

AC 2000V; fully immerse the heating area in water for 1 second. |

|

Leakage current |

Temperature: 23℃±3℃ Humidity: 65%±10% |

<0.5mA |

To test leakage, apply a current of 1.06 times the rated voltage. |

|

Insulation resistance |

Temperature 23℃±3℃ Humidity 65%±10% |

>100MΩ |

DC 500V; heating area completely immersed in water. |

|

Durability |

Power on the water, the water temperature is 40±5°C |

No damage |

1. Power on continuously 5,000 times. 2. In water, power on for 10 seconds, then off for 10 seconds, and then cycle 100,000 times. |