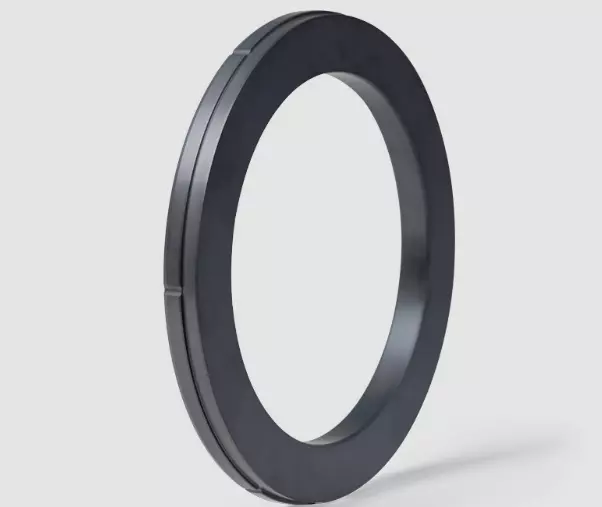

Silicon carbide (SiC) is used in seal rings of your mechanical seals due to its exceptional chemical inertness and hardness. Your silicon carbide seals offer a more reliable solution in applications where chemical attack and leakage risks affect productivity.

What Is Silicon Carbide?

Definition of Silicon Carbide (SiC)

- Dein Siliziumkarbid (SiC) is a chemical compound that has both carbon and silicon. SiC is a very hard, synthetic Keramik material with a wide band gap. This makes it ideal for your seal face materials operating in caustic environment.

-

The compound delivers superior thermal, high-temperature, and high-voltage characteristics. Thus, SiC is used in your electronics, abrasives, and industrial equipment, including seal faces in chemically corrosive conditions.

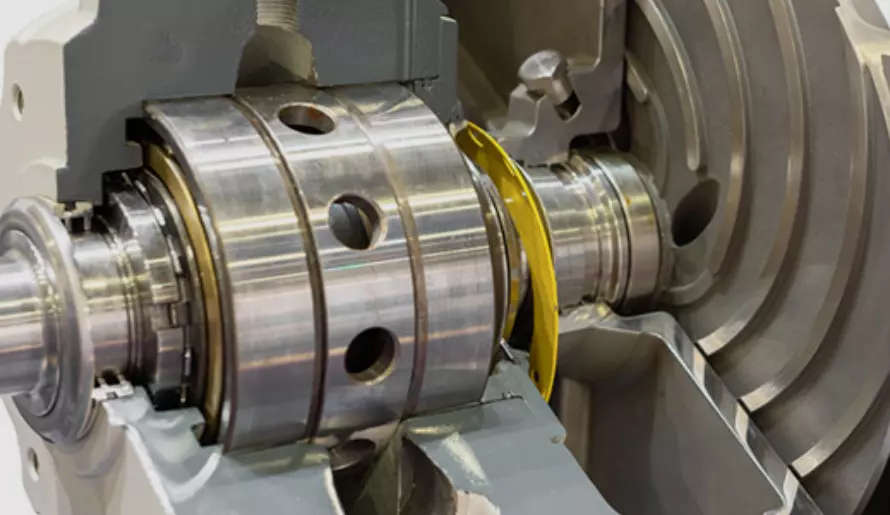

What Is a Mechanical Seal?

Definition of Mechanical Seals Materials

-

A mechanical seal is a device that helps join your rotating equipment. It helps prevent gas or liquid leaks in your pumps, compressors, and mixers, where leakage could compromise safety.

Definition of Silicon Carbide Mechanical Seal

-

Your silicon carbide mechanical seal is a seal component that delivers high performance. Its faces are made from a 9-9.5 Mohs hardness, 99.99% purity and chemically inert ceramic. This ensures your seal integrity is maintained under corrosive conditions.

Silicon Carbide Mechanical Seal Properties

Is SiC Chemically Inert?

-

Yes, your silicon carbide delivers exceptional corrosion resistance. Since SiC is chemically inert, your silicon carbide mechanical seals resist chemical attacks, acids, and other aggressive fluids. Thus, reliability increases by up to 65%+ in your chemical processing.

What’s the Hardness of Silicon Carbide Seals?

-

With a vickers hardness of 2500kg/mm2 and 9-9.5 on the Mohs scale, your SiC hardness nears that of diamond.

-

Due to this high hardness, wear resistance (ability to withstand surface material loss) increases by >40% in your abrasive media. This reduces wear of the seal surfaces and cuts on replacements.

What’s the SiC’s Thermal Conductivity?

-

Your silicon carbide mechanical seal thermal conductivity reaches 120 to 490 W/m·K, depending on the prototype used.

-

Due to this high thermal conductivity and SiCs low Wärmeausdehnung, your seals achieve uniform heating with low cracking risk.

Do Silicon Carbide Mechanical Seals Withstand High Temperatures?

-

Your silicon carbide mechanical seals operate reliably in 1750 °C. This extreme heat resistance ensures SiC retains its chemical characteristics in your high-temperature chemical processing. If carbon is used in your high-temperature chemical reactions, seal deformation would cause leaks.

What’s the Friction Coefficient of SiC Seal Rings?

-

Silicon carbide mechanical seals provide a low friction coefficient of about 0.02–0.1. This ensures your mechanical seals survive dry-running and ensure high efficiency in your industry operation. It also reduces risk of surface damage during start-ups.

“After switching to silicon carbide mechanical seals, wear resistance increased by 40% in our abrasive media pumps.” – Huang T., Reliability Engineer, Slurryseals

Types of Silicon Carbide Mechanical Seals Materials

Sintered Silicon Carbide (SSiC)

-

SSiC provides higher chemical resistance than RBSiC and VSG1. I consider SSiC the best choice for corrosive environments because it’s actually 99.999% pure SiC. Since it doesn’t have the free silicon found in other types, it resists almost all chemicals in your industry.

Reaction-Bonded Silicon Carbide (RBSiC)

-

RBSiC is also used for corrosion resistance. However, it contains free silicon. This makes it less ideal in strong acid or base operations.

Graphite-Loaded SiC (VSG1)

-

VSG1 blends silicon carbide with graphite. This improves self-lubrication properties, and thus reduces friction.

Wolfram Carbide Vs Silicon Carbide Mechanical Seal

-

From a corrosion resistance and leakage risk perspective, silicon carbide vs Tungsten carbide mechanical seal, SiC offers better performance. SiC outperforms Tungsten carbide in your high-temperature, corrosive and low lubrication applications.

Properties Comparison of Tungsten Carbide Vs Silicon Carbide Mechanical Seals

TungstenCarbideVsSiliconCarbide_Table1.png

|

Eigentum |

Silicon Carbide Face Seal |

Tungsten Carbide Face Seal |

|

Korrosionsbeständigkeit |

Inert (highly resistant to acids, alkalis, solvents) |

Moderate (susceptible to chemical erosion/oxidation) |

|

Härte (Mohs) |

9-9.5 (second to diamond) |

8.5 (high but susceptible to chemical erosion) |

|

Verschleißfestigkeit |

Superior (exceptionally resists heavy abrasives) |

Excellent (good alternative for abrasive slurry) |

|

Wärmeleitfähigkeit |

120-490 W/m·K (high, thus prevents thermal-cracks) |

W/m·K 84–100 (moderate, thus prone to heat-cracking) |

|

Bruchzähigkeit |

Moderate (brittle) |

Very tough (resists breaking under mechanical impact) |

|

Wärmeausdehnung |

4.0–4.5 x 10⁻⁶/°C (low, thus ensures dimensional stability) |

5.0–6.0 x 10⁻⁶/°C (moderate) |

|

Operating Temperature (°C) |

1750 |

600-1000 |

|

Reibungskoeffizient |

0.02–0.1 (lower, thus less energy loss & improved dry-running) |

0.08–0.15+ (higher, thus requires better lubrication) |

|

Typical Use |

High corrossion, high-temperature, high-purity, & dry-running applications |

High-pressure, heavy slurry applications |

Table: Features comparison of tungsten carbide vs silicon carbide mechanical seals

Data source: Mater. Sci. Eng. 2025; 109(2): 021004

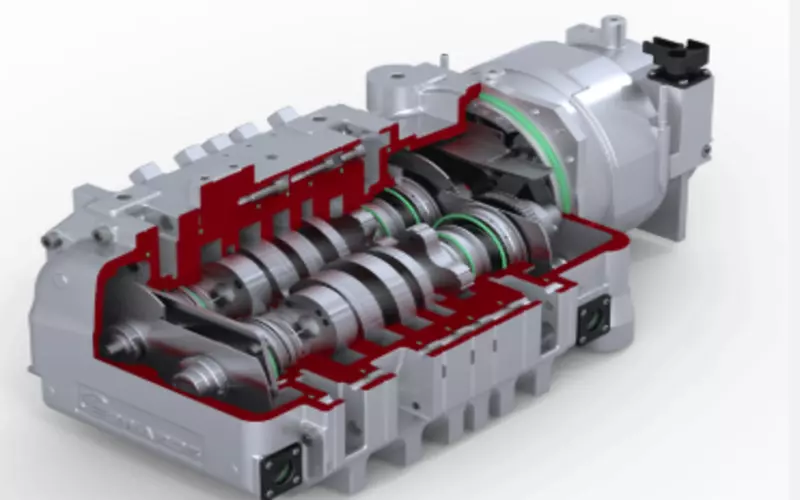

Anwendungen von Silicon Carbide Mechanical Seals

In Chemical and Petrochemical Processing

-

Silicon carbide seals meet strict leakage requirements in your agitators, reactors, and sealing pumps. Due to its exceptional corrosion resistance, SSiC resists the strong acids, alkalis and chemicals in your chemical processing application.

In Your Oil and Gas Production

-

Silicon carbide mechanical seals are used in your drilling equipment, processing plants and crude oil pumps. Since SiC has Superior stiffness and low deformation under high PV, your SiC seal rings withstands high pressure.

Your Water and Wastewater Treatment

-

In your industrial water systems and wastewater treatment, SiC mechanical seals are preferred. Due to their hardness, SiC seals resists damage from abrasive particles and chemicals.

In Food and Pharmaceutical Industries

-

In your food and pharmaceutical production, SiC mechanical seals are used for sanitary pumps and mixers. Due to the chemical inertness and 99.99% purity of SiC, contamination risk reduces by up to 50% in your industry.

In Your Industrial Machinery

-

Your gas turbines, compressors, automotive engines and vacuum pumps would degrade if carbon or Tungsten carbide was used.

-

With thermal conductivity 120-490 W/m·K and high thermal shock resistance, your SiC seals operate reliably under 1750°C+.

Your Silicon Carbide Mechanical Seal Selection

Which SiC Mechanical Seals Materials to Choose

-

If your operation demands exceptional corrosion resistance and hardness, SSiC is the best solution.

-

If the priority is cost-effectiveness and capability for complex shapes, buy RBSiC.

-

If your industry prioritizes self lubrication and dry-running, graphite-loaded SiC is the most effective mechanical seal option.

Where to Buy Your Silicon Carbide Seal

-

Look for manufacturers and suppliers who are committed to UL standards, ISO 9001 &14001 and ASTM F1241 quality standards. Many SiC mechanical seal suppliers in China offer 2400-2500 HV products and technical support.

Bei GORGEOUS CERAMIC( GGSCERAMIC), we guarantee ISO 9001:2025 silicon carbide mechanical seals that achieve weight loss <2mg/cm²/year in your corrosive media.

FAQs About Silicon Carbide Mechanical Seal

Q: What is a mechanical seal?

A: It’s a device that helps join the faces of your rotating equipment to prevent leakage of gas or liquids.

Q: What are the silicon carbide mechanical seal properties?

A: Your silicon carbide mechanical seal delivers 9-9.5 Mohs hardness, exceptional corrosion resistance, high-temperature resistance and 99.99% purity.

Q: Silicon carbide is used as seal rings in what applications?

A: SiC mechanical seal rings are used in your chemical processing, food production, high-pressure and high-speed pumping systems.

Abschluss

Your silicon carbide mechanical seal delivers superior corrosion resistance, higher hardness, and lower friction than tungsten carbide and carbon seals. Due to these outstanding properties, your SiC mechanical seals are preferred for reduced leakage risk and longer service life.