المزود الرائد عالميًا لحلول سيراميك كربيد السيليكون

15+ سنوات من شركة إس إس آي سي و السيسي خبرة في مبيعات المنتجات والإنتاج، وتخصيص أجزاء الهياكل الخزفية المصنوعة من كربيد السيليكون في مختلف المجالات بالنسبة لك

سيراميك كربيد السيليكون/سيراميك SIC

قم بتخصيص السيراميك الخاص بك

سيراميك كربيد السيليكون: حلول مواد عالية الجودة مصممة خصيصًا لمجالك

في خلابنحن نصمم سيراميك كربيد السيليكون (SiC) عالي الأداء للصناعات التي لا تلبي احتياجاتها المواد القياسية. سواءً كانت احتياجاتك تتطلب مقاومة شديدة للحرارة، أو مقاومة للتآكل، أو استقرارًا كيميائيًا، فإن حلول كربيد السيليكون المخصصة لدينا مصممة لأداء موثوق في أكثر البيئات تطلبًا.

⬜️ التطبيقات الحرارية ودرجات الحرارة العالية

➡️ بوتقات، أثاث الفرن، أنابيب حماية حرارية

⬜️ المقاومة الميكانيكية والتآكل

➡️ الأختام، الأجزاء المقاومة للتآكل، الذراع الخزفي

⬜️ التحكم الدقيق في السوائل والغازات

➡️ فوهات رش اللهب، قنوات الهواء البارد

⬜️ قطاعات التكنولوجيا المتقدمة

➡️ مكونات أشباه الموصلات، دروع مضادة للرصاص

أخبرنا بمتطلباتك - وسنقدم لك حلًا مخصصًا لمكونات SiC لتطبيقك.اتصل بنا] للحصول على استشارة فنية مجانية.

البحث والتطوير لتخصيص تطبيق سيراميك كربيد السيليكون الخاص بك

◽️أبحاث المواد

خلاب سنجري أبحاثًا متعمقة على المواد عالية التقنية وفقًا لطلب السوق ومتطلباتكم الخاصة لأداء المنتج، مع مراعاة شاملة للعوامل الرئيسية مثل نقاء المادة، والخصائص الميكانيكية، والخصائص الكهربائية، والخصائص الحرارية، ومقاومة درجات الحرارة العالية، ومقاومة التآكل، ومقاومة الصدمات، واختيار أفضل نظام مواد ونظام إضافات. نستخدم أساليب تصميم الصياغة، مثل تصميم تاجوشي، وتحليل وزارة الطاقة أحادي العامل أو متعدد العوامل متعدد المستويات، لتحسين نسبة المواد، ونُحضر العينات بالتزامن مع عمليات الصب والتلبيد المقابلة، ونُجري عمليات التلميع والتآكل وغيرها من المعالجات. وأخيرًا، نُجري تقييمًا شاملًا بناءً على معايير العملية، والهيكل التنظيمي، وأداء تركيبة المادة، لضمان تلبية منتجاتكم للمتطلبات المتوقعة وتقديم أفضل النتائج. سيراميك كربيد السيليكون لك.

◽️التصميم الهندسي

بعد استلام متطلباتك، خلاب سنرشدك لربط تصميم المنتج والهندسة مع مهندسي التصميم الهندسي المحترفين لدينا ومهندسي المنتجات. بعد مناقشات معمقة، سنُجري مجموعة كاملة من تصميمات المنتجات الهندسية بناءً على احتياجاتك وسيناريوهات تطبيقك والخصائص التقنية للشركة.

◽️تحسين العمليات

نضع جودة المنتج، والإنتاجية، ووقت التسليم، ورضا العملاء في المقام الأول. سيحرص مهندسو العمليات وكبار المديرين لدينا على طرح احتياجات التكنولوجيا وتحسين العمليات والتكرار، ثم يُسلمونها إلى قسم البحث والتطوير لبدء مشاريع تحسين العمليات، وتحسين العمليات المقابلة، وتقديم منتجات عالية الجودة لكم دائمًا.

◽️تصميم القالب

رائع يتمتع فريق هندسة التصميم بخبرة ومعرفة واسعة بخصائص القولبة والتلبيد والمعالجة لمختلف أنظمة المواد والمنتجات. ويمكنهم اختيار مواد القالب المناسبة بدقة واستخدامها. كاد, سوليدووركس, يو جي وبرامج تصميم أخرى لتصميم قوالب متطابقة. يمكنك اختيار أنواع مختلفة من القوالب مثل معالجة القوالب, قوالب الطباعة ثلاثية الأبعاد, قوالب الصب, رغوة مفقودة أو قوالب خفيفة الوزن نوفر حلولاً إنتاجية تناسب احتياجاتكم، سواءً كانت كبيرة أو سميكة الجدران أو طويلة أو سميكة جدًا أو معقدة.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

مميزات منتجات سيراميك كربيد السيليكون الرائعة

نقاء عالي

الاستقرار الكيميائي

مقاومة درجات الحرارة العالية

مضاد للأكسدة

يمكن لشركة GORGEOUS أن تزودك بمواد كربيد السيليكون

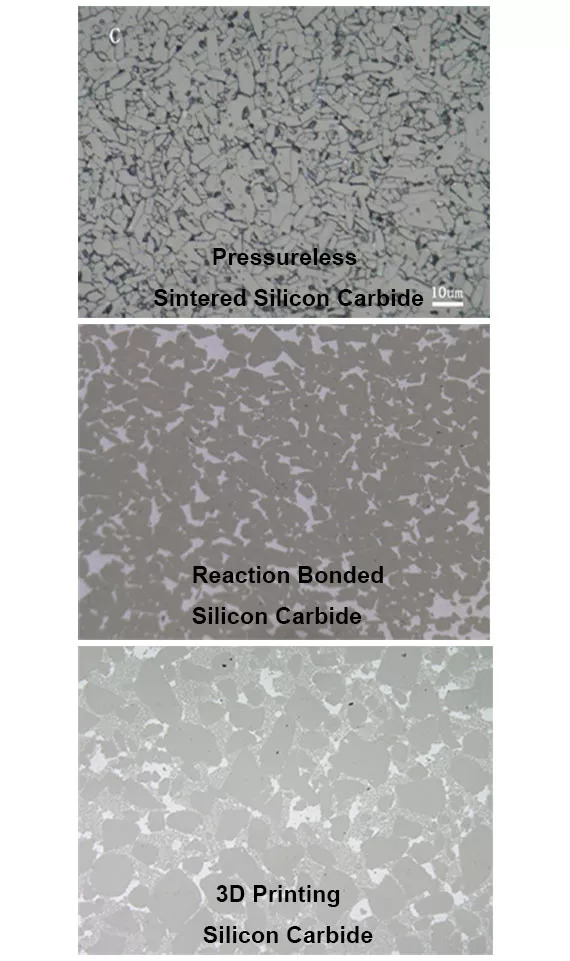

⬜️كربيد السيليكون المتكلس بدون ضغط

- يمكن أن يصل حجم الجسيمات إلى 0.5-1.0 ميكرومتر.

- صلابة عالية للغاية، ومقاومة ممتازة للتآكل، تتجاوز صلابة فيكرز 2000 جيجا باسكال.

- قوة انحناء ممتازة، قوة انحناء ثلاثية النقاط أكبر من 350 ميجا باسكال.

- مقاومة درجات الحرارة العالية تصل إلى 1500درجة مئوية.

- موصلية حرارية عالية ومعامل تمدد حراري منخفض (موصلية حرارية في درجة حرارة الغرفة)>120 واط/م·ك، درجة حرارة الغرفة CTE<2.5 جزء في المليون/درجة مئوية).

- مقاومة شاملة للتآكل الكيميائي.

- يمكننا تخصيص أجزاء السيراميك ذات الهياكل المعقدة الكبيرة الحجم والمتنوعة لك.

⬜️كربيد السيليكون المتفاعل

- قوة انحناء ممتازة (>280 ميجا باسكال, 3 مرات من مادة الكوارتز)

- يمكن أن تصل درجة حرارة التشغيل القصوى إلى 1350درجة مئوية

- مستقر كيميائيًا، ومقاوم للتآكل الحمضي والقلوي، ومعدل حفر منخفض للغسيل الحمضي والقلوي

- معامل التمدد الحراري المنخفض، مماثل لمعامل التمدد الحراري للمواد مثل نتريد السيليكون

- مقاومة ممتازة للتآكل والصلابة (>2500 جيجا باسكال)

- موصلية حرارية ممتازة (موصلية حرارية في درجة حرارة الغرفة)>160 واط/م·ك)

⬜️الطباعة ثلاثية الأبعاد باستخدام كربيد السيليكون

- حجم الجسيمات عادة ما يكون 50-100 ميكرومتر

- مقاومة ممتازة للتآكل (صلابة فيكرز > 20 جيجا باسكال)

- مقاومة درجات الحرارة العالية، يمكن أن تتحمل 1300درجة مئوية

- موصلية حرارية عالية، معامل تمدد حراري منخفض (موصلية حرارية في درجة حرارة الغرفة) > 100 واط/م·ك، درجة حرارة الغرفة CTE < 4*10-6 /ك)

- يمكن أن تصل النقاء إلى 99.98%

- يمكن تصنيع أجزاء هيكلية كبيرة الحجم ومعقدة متنوعة لك

معلمات واختيار مواد الذراع المخصصة

كربيد السيليكون المتكلس بدون ضغط

كربيد السيليكون المتفاعل

الطباعة ثلاثية الأبعاد لسيراميك كربيد السيليكون

ابحث عن منتجات سيراميك كربيد السيليكون لتطبيقك

⬛منتجات تفاعلات القنوات الدقيقة

باعتبارها المكون الأساسي للمفاعل/المعدات الكيميائية ذات التدفق المستمر الدقيقة، فإن مفاعل القناة الدقيقة المصنوع من كربيد السيليكون يمكنه حل مشاكل تطبيقاتك الكيميائية بشكل فعال.

يمكن لشركة GORGEOUS تخصيص العديد من منتجات تفاعل القنوات الدقيقة لك: أنبوب تفاعل كربيد السيليكون، لوحة تفاعل دقيقة من كربيد السيليكون، وحدة تفاعل دقيقة من كربيد السيليكون

![]()

⬛منتجات تبادل حراري مقاومة للتآكل

تُستخدم سيراميكات كربيد السيليكون بشكل شائع في عمليات مثل التبريد والتكثيف والتسخين والتبخير وتبخير الأغشية الرقيقة وامتصاص المواد الكيميائية شديدة التآكل. تتميز سيراميكات كربيد السيليكون بأداء أفضل وفوائد إجمالية أعلى من معدات التبادل الحراري التقليدية.

يمكن لشركة GORGEOUS تخصيص العديد من منتجات التبادل الحراري المقاومة للتآكل لك: لوحة تبادل حراري من كربيد السيليكون، كتلة حزمة أنبوب كربيد السيليكون، ورقة أنبوب كربيد السيليكون، ثقب كتلة تبادل حراري من كربيد السيليكون، رأس كربيد السيليكون، أنبوب تبادل حراري من كربيد السيليكون، غلاف حماية مقياس حرارة من كربيد السيليكون.

![]()

⬛منتجات مقاومة لدرجات الحرارة العالية

تتمتع سيراميك كربيد السيليكون من GORGEOUS بمقاومة قوية للغاية لدرجات الحرارة العالية ويمكنها تحمل درجات حرارة تصل إلى 1650 درجة مئوية، مما يوفر أفضل حل لتطبيقات درجات الحرارة العالية.

يمكن لشركة GORGEOUS تخصيص العديد من منتجات سيراميك كربيد السيليكون المقاومة لدرجات الحرارة العالية لك: بوتقات كربيد السيليكون، أنابيب حماية ترموكبل كربيد السيليكون، لوحات إشعاع حراري من كربيد السيليكون، أنابيب إشعاع حراري من كربيد السيليكون، أكمام موقد كربيد السيليكون الملبدة بالتفاعل، البطانات الخزفية من كربيد السيليكون، إلخ.

![]()

⬛منتجات مقاومة للتآكل

تُقدّم لكم شركة GORGEOUS منتجات سيراميكية مقاومة للتآكل، مثل بطانات طحن كربيد السيليكون، المُزوّدة بهياكل طحن وقنوات تبادل حراري داخلية. يصل أقصى قطر خارجي لها إلى 1300 مم، وارتفاعها إلى 1200 مم، مما يضمن كفاءة طحن عالية.

يمكن لشركة GORGEOUS أيضًا أن تزودك بمنتجات مقاومة للتآكل مخصصة أخرى: أقراص الطحن المطبوعة ثلاثية الأبعاد، فوهات إزالة الكبريت من كربيد السيليكون، مروحة كربيد السيليكون، فوهات السفع الرملي من كربيد السيليكون، فوهات ذرات حمض الكبريتيك من كربيد السيليكون، أسطوانات طحن كربيد السيليكون، إلخ.

![]()

⬛منتجات مقاومة للحفر الأيوني

يمكن لشركة GORGEOUS أن تزودك بهياكل حاملة سيراميك مخصصة مناسبة لعملية النقش ICP، وعملية PVD، وعملية RTP، وعملية CMP في تصنيع رقائق الإضاءة الضوئية الإلكترونية.

يمكن لشركة GORGEOUS تخصيص منتجات سيراميك كربيد السيليكون المقاومة للحفر الأيوني لك: حامل PVD من كربيد السيليكون، حامل ICP من كربيد السيليكون

![]()

⬛منتجات مقاومة للصدمات الحرارية

يمكن لشركة GORGEOUS أن تزودك بمنتجات مخصصة لتطبيقات مقاومة الصدمات الحرارية: مادة الكابولي من كربيد السيليكون، شعاع الكابولي من كربيد السيليكون، دعامة قارب من كربيد السيليكون، أنبوب هواء من كربيد السيليكون، حامل RTA من كربيد السيليكون، إلخ.

![]()

⬛منتجات عالية النقاء

يمكن أن توفر لك GORGEOUS سيراميك كربيد السيليكون عالي النقاء، مع نقاء مادة أساسية تصل إلى 99.99%، ونقاء طلاء كربيد السيليكون السطحي يصل إلى 99.999%، ومقاومة درجات الحرارة العالية تصل إلى 1650 درجة مئوية، مما يضمن استقرار تطبيقاتك ذات درجات الحرارة العالية.

يمكن لشركة GORGEOUS تخصيص منتجات كربيد السيليكون عالية النقاء لك: أنابيب فرن كربيد السيليكون، أقراص طلاء كربيد السيليكون لتكوين طبقات السيليكون، ملاط ذراع كربيد السيليكون

![]()

⬛منتجات حماية الدروع

يتمتع كربيد السيليكون بصلابة عالية للغاية ويُستخدم على نطاق واسع في أنظمة الدروع.

يمكن لشركة GORGEOUS أن تزودك بالسيراميك الواقي المخصص: حشوات كربيد السيليكون المضادة للرصاص، وصفائح SIC المضادة للرصاص، وما إلى ذلك.

![]()

مجالات تطبيق سيراميك كربيد السيليكون

الزجاج الإلكتروني

يتميز كربيد السيليكون بخصائص ممتازة في درجات الحرارة العالية (قوة، مقاومة للأكسدة، زحف منخفض)، وكثافة عالية، ومسامية منخفضة، وشوائب منخفضة. وهو مادة مثالية للمكونات المقاومة للحرارة في عملية تشكيل الزجاج الإلكتروني. ويُستخدم غالبًا في آلات ثني الزجاج الساخن، وآلات تشكيل الزجاج اللاكروي، وغيرها من المعدات، مثل مشتتات الحرارة الخزفية المصنوعة من كربيد السيليكون، وأكمام قوالب كربيد السيليكون، وقوالب كربيد السيليكون، وألواح تسخين كربيد السيليكون، وغيرها.

مواد البطارية

تُستخدم بكرات وعوارض كربيد السيليكون المربعة على نطاق واسع في أفران التلبيد لمواد الأقطاب الموجبة والسالبة لبطاريات الليثيوم. بالإضافة إلى ذلك، يُمكن استخدام أجزاء كربيد السيليكون المقاومة للتآكل، ذات الصلابة والمتانة العاليتين، في معدات معالجة المساحيق، مثل صنفرة وتشتيت مواد بطاريات الليثيوم. تشمل منتجات سيراميك كربيد السيليكون الشائعة الاستخدام في صناعة مواد البطاريات: عوارض كربيد السيليكون المربعة وعوارض كربيد السيليكون المربعة شبه المفتوحة، وبكرات كربيد السيليكون، وأنابيب أفران كربيد السيليكون، وأسطوانات طحن كربيد السيليكون، وغيرها.

أشباه الموصلات

تتميز مواد سيراميك كربيد السيليكون بقوة وصلابة ومرونة عالية وموصلية حرارية عالية ومعامل تمدد حراري منخفض، بالإضافة إلى صلابة نوعية ممتازة وأداء معالجة بصرية ممتاز. وهي مناسبة بشكل خاص لبعض الملحقات الدقيقة لمعدات أشباه الموصلات. على سبيل المثال، تُستخدم في آلات الطباعة الضوئية، وروبوتات مناولة الرقاقات، وغيرها. من منتجات كربيد السيليكون الشائعة الاستخدام: ملاط ذراع كربيد السيليكون، ورأس حلقي من كربيد السيليكون، ورأس فراغ من كربيد السيليكون، وذراع روبوتية من كربيد السيليكون، وغيرها.

الكيميائية والصيدلانية

سيراميك كربيد السيليكون مناسب جدًا لمعدات التبريد والتكثيف والتسخين والتبخير وتبخير الأغشية الرقيقة والامتصاص للمواد الكيميائية شديدة التآكل. بالمقارنة مع معدات التبادل الحراري التقليدية، تتميز معدات التبادل الحراري المصنوعة من كربيد السيليكون بكفاءة تبادل حراري أفضل، مما يجعلها أكثر إحكامًا وصغرًا في الحجم وسهولة الفك وانخفاض تكاليف الصيانة. تشمل منتجات سيراميك كربيد السيليكون الشائعة: أنابيب كربيد السيليكون، وثقوب أنابيب التبادل الحراري المصنوعة من كربيد السيليكون، ورؤوس أنابيب التبادل الحراري المصنوعة من كربيد السيليكون، وغيرها.

صناعة الأغذية والأدوية

لا تحتوي المواد السيراميكية على ترسب أيوني معدني وهي مناسبة لمجالات مثل معالجة الأغذية والتعبئة والتغليف الصيدلانية التي تتطلب نظافة مادية عالية للغاية.

خدمة تصنيع سيراميك كربيد السيليكون الشاملة

15+ سنوات من الخبرة. دقة عالية وتصميم OEM. فريق بحث وتطوير محترف. أسعار تنافسية.

ما هي المزايا الرئيسية لسيراميك كربيد السيليكون (SiC) مقارنة بالمواد الأخرى؟

توفر سيراميك كربيد السيليكون أداءً ممتازًا للتطبيقات الصعبة.

- مقاومة درجات الحرارة العالية - (تصل إلى 1650 درجة مئوية) مثالية لمكونات الفرن أو الفضاء

- صلابة عالية للغاية (صلابة موس 9.5) أفضل من الألومينا والزركونيا

- خامل كيميائيًا، ومقاوم للتآكل الحمضي والقلوي

- الموصلية الحرارية أفضل من معظم سيراميك المبادل الحراري

هل يمكن تشكيل سيراميك SiC إلى أشكال معقدة؟

نعم، تتشكل أشكال SiC المسحوقة بالقرب من الأشكال الصافية أثناء التلبيد؛ تتطلب مرحلة ما بعد التصنيع أدوات ماسية (مكلفة)؛ يسمح SiC المترابط بالتفاعل بمرونة أكبر في التصنيع قبل التلبيد النهائي؛ الطباعة ثلاثية الأبعاد، وهي تقنية ناشئة للنماذج الأولية.