Brittleness is a common fatal weakness of inorganic non-metallic materials, and in ceramics, it manifests as a sudden and unpredictable fracture under applied loads. Indirectly, it leads to poor resistance to mechanical impacts and rapid temperature changes.

Brittleness is a crucial characteristic for evaluating ceramic material performance and represents a significant flaw in ceramic density.

The essential nature of ceramic brittleness is primarily determined by the properties of chemical bonds and crystal structure. Ceramics lack independent slip systems, making it difficult for materials to relax stress through plastic deformation caused by slip once they are under stress. Microscopically, the root cause of brittleness lies in the existence of microcracks, which are prone to inducing highly concentrated stress, leading to crack propagation and ultimately fracture.

The brittle characteristics of ceramic materials:

- Covalent Bond Characteristics:

In ceramic materials, the atoms forming chemical bonds have many voids between them, making it difficult to induce dislocation movement.

Covalent bonds are directional, leading to complex crystal structures with high resistance to distortion and hindrance to the movement of atoms.

- Microstructural Characteristics:

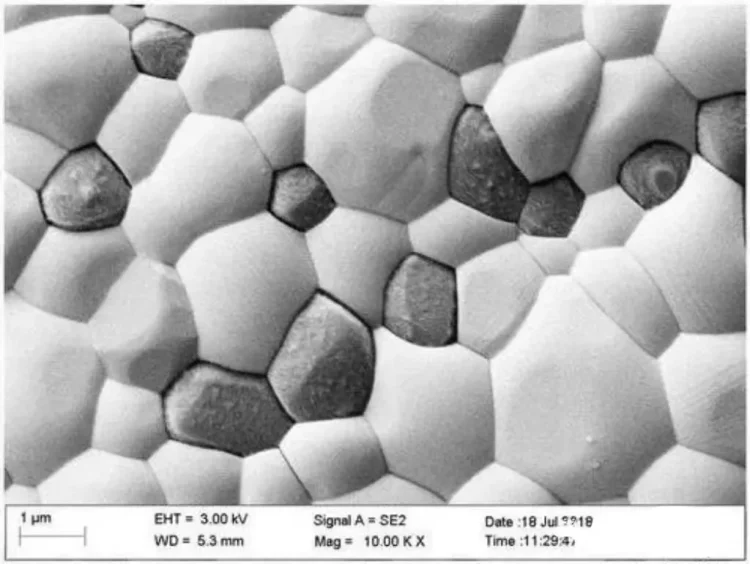

Ceramic materials are polycrystalline and exhibit multiphase structures. Grain boundaries in ceramics impede dislocation movement, and accumulated displacement can lead to crack formation. Additionally, the presence of point, line, and planar defects in actual crystal structures, along with the existence of micro and sub-microscopic cracks within them, inevitably results in structural non-uniformity.

Moreover, microstructural factors such as grain boundaries, pores, phases, phase inclusions, and cracks can all contribute to the brittleness of ceramic materials.

- Lack of Plastic Deformation Characteristics:

At room temperature, most ceramic materials exhibit minimal or no plastic deformation under external forces. This results in ceramic materials fracturing abruptly, exhibiting brittleness.

The fracture of ceramic materials

Brittle fracture occurs when a material is subjected to stress and stress redistribution occurs at levels below its own cohesive strength. However, when the rate of externally applied stress exceeds the rate of stress redistribution without any other energy absorption process, stress cannot relax, leading to concentrated expansion of cracks. This results in a very rapid crack propagation, ultimately leading to sudden failure.

Brittle fracture marks the termination of crack propagation.

Brittle fracture of advanced ceramics

The Relationship between Microstructure and Brittleness:

- Grain Size and Cracks:

Due to the complexity of ceramic preparation processes, the presence of intragranular cracks is almost unavoidable. Reducing grain size can improve the brittleness of ceramic materials.

Smaller grain size and increased grain boundaries can increase resistance to crack propagation.

The stress concentration effect in fine grains is smaller than that in coarse grains.

Elastic and thermal anisotropy in coarse grains often lead to the occurrence of microcracks, resulting in increased internal stress and reduced fracture energy.

- Porosity and Cracks:

The strength and elastic modulus of ceramic materials decrease with increasing porosity. Increased porosity reduces material density, effectively decreasing the load-bearing area. Pores located at grain boundaries cause stress concentration and are prone to crack formation under external loads.

As porosity increases, the contact area between grains decreases, and the distance between pores shortens, facilitating crack formation and propagation, thereby increasing material brittleness.

Pores at multiphase boundaries themselves act as crack initiators.

- Grain Boundaries and Cracks:

In ceramic materials composed of a single crystal phase, cracks that propagate under external forces often stop at grain boundaries. However, if there are pores or stress concentration at grain boundaries, cracks may extend along the grain boundaries. Impurities and secondary phase grains in grain boundaries of polycrystalline materials sometimes serve as pathways for crack propagation due to their brittleness and anisotropy, while at other times, they act as barriers due to their high energy barriers, preventing crack propagation.

Grain boundaries and cracks

Common Solutions to Improve the Brittleness of Ceramic Materials:

- Increasing the number of microcrystals to enhance ceramic density and purity:

Improve the quality of raw materials: Ensure that the powder is as fine as possible and has uniform particle size and shape, with good chemical purity and a single-phase structure, while meeting other process requirements.

Scientifically select sintering temperature and optimize process conditions to prevent grain growth.

Determine appropriate additives and their quantities to suppress abnormal grain growth and promote densification.

Advanced ceramic materials increase the number of microcrystals to enhance density and purity

- Toughening through phase transformation:

Overcoming ceramic brittleness by controlling phase transformations within the ceramic body. This involves utilizing the volume changes that occur during phase transformations to reduce stress concentration at crack tips, thereby improving ceramic toughness.

Phase transformation for toughening advanced ceramics

- Toughening with composite materials:

Adding another type of particle material or fiber material to the ceramic matrix to form a composite material for toughening purposes.

Plastic deformation of particles can absorb some energy, thereby partially alleviating the highly concentrated stress at the crack tip region, improving the material’s resistance to crack propagation.

High-strength, high-modulus fibers can both share most of the externally applied stress with the matrix and prevent crack propagation within the matrix.

Reinforcement of ceramic matrix with composite materials for improved toughness

- Pre-stressing:

Introducing residual stress artificially on the material surface through appropriate heating and cooling processes can enhance the material’s tensile strength and improve its brittleness.

This method not only induces compressive stress on the surface but also refines grain size.

- Process optimization:

Controlling process conditions reasonably to make the ceramic structure as uniform and dense as possible, reducing pores, minimizing cracks, and improving brittleness.