Berkomitmen untuk memberi Anda kustomisasi ukuran dan bentuk khusus serta memecahkan perbedaan warna batch penyedia lengan keramik!

Pemasok Lengan Keramik/Efektor Ujung Keramik

Sesuaikan Keramik Anda

Deskripsi Lengan Keramik

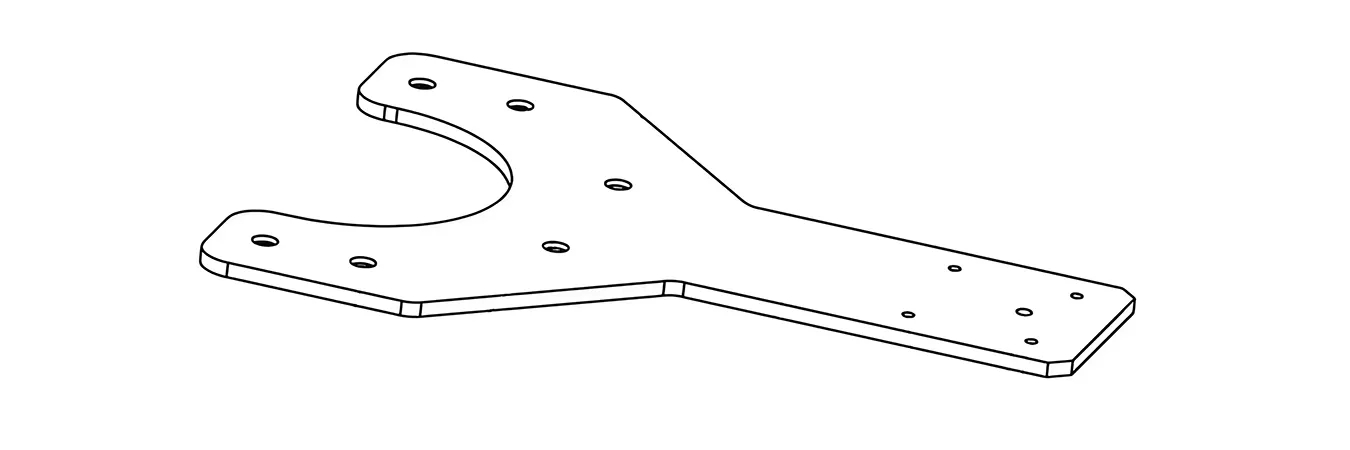

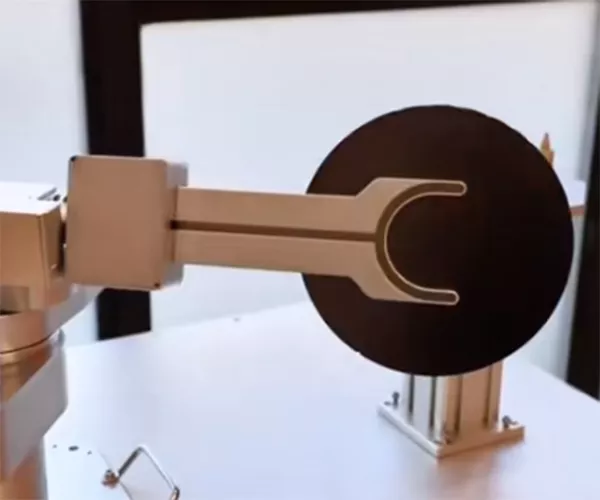

Lengan robot keramik, juga dikenal sebagai jari robot keramik, nampan wafer, lengan robot wafer bundar, dll., terutama digunakan untuk transportasi dan penanganan peralatan semikonduktor, dan bertanggung jawab untuk mengirimkan wafer silikon wafer ke lokasi yang ditentukan.

Fitur produk yang LUAR BIASA:

▫️Presisi produk tinggi

▫️Kedap udara yang sangat baik

▫️Ketahanan suhu tinggi yang baik

▫️Resistivitas permukaan yang dapat dikontrol

▫️Ketahanan asam dan alkali yang kuat serta ketahanan korosi, dapat beradaptasi dengan berbagai lingkungan yang sangat keras

🔷Uji kekencangan sendiri: turn off the vacuum air source, negative pressure –85Kpa ke -80Kpa, selama lebih dari tahun 60an

🔷Uji adsorpsi wafer: matikan sumber udara vakum, tekanan negatif -80Kpa ke -25Kpa, selama lebih dari 35 detik

Jaminan Waktu Pembuatan & Pengiriman

GORGEOUS adalah produsen keramik terkemuka untuk pemrosesan wafer semikonduktor. Kami memiliki 15 Berbekal teknologi dan pengalaman bertahun-tahun dalam memproduksi keramik canggih, kami terus mengoptimalkan dan meningkatkan proses manufaktur keramik semikonduktor. Kami dapat menyesuaikan berbagai komponen untuk Anda, seperti lengan keramik, efektor ujung robot, chuck wafer keramik, dll.

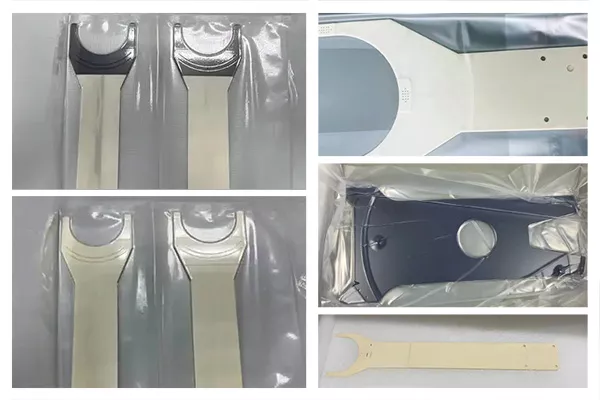

Pengemasan lengan keramik dapat didasarkan pada kebutuhan Anda, menggunakan bahan keras yang ramah lingkungan atau pelindung busa yang lembut.

Keramik kami dikirim ke seluruh dunia, dan pengirimannya bergantung pada lokasi Anda. Kami akan segera memproduksi sesuai rencana Anda dan memilih metode pengiriman terbaik. Pengangkutan udara tercepat di Amerika Utara, tiba dalam 7 hari.

GORGEOUS memilih untuk bekerja sama dengan beberapa perusahaan logistik terkemuka, termasuk:

- MSC (Perusahaan Pengiriman Mediterania)

- Bahasa Indonesia: Maersk

- CMA CGM

- COSCO

- Hapag Lloyd

- Bahasa Indonesia: DHL

- UPS

- Layanan FedEx

- TNT

Kami bekerja sama dengan banyak freight forwarder untuk menjamin Anda pilihan pengiriman yang efisien dengan harga yang lebih rendah, pengiriman tepat waktu, Dan tidak ada biaya tersembunyi!

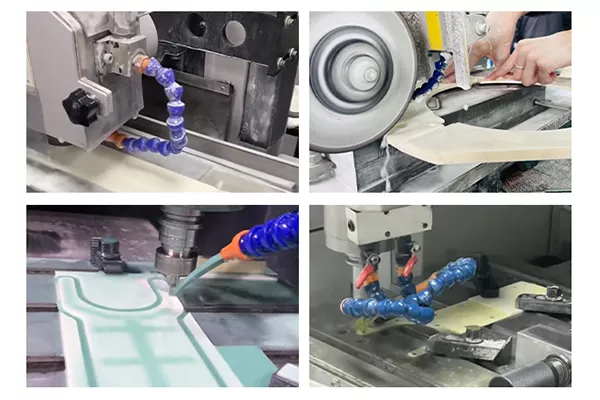

Manufaktur

Sedang mengemas

Memuat

Angkutan

Kinerja Utama Lengan Keramik/Efektor Ujung Keramik

Ringan

Tahan Aus

Tahan Korosi

Tahan Suhu Tinggi

Isolasi Kuat

Referensi Akurasi Produk yang Dapat Disesuaikan dan LUAR BIASA

| Minimum | Maksimum | |

| Ketebalan Keseluruhan | 1,5 mm | 4 mm |

| Ketebalan Rongga | 0,5 mm | 0,7 mm |

| Ketebalan Celah Antara Rongga dan Permukaan | 0,5 mm | – |

| Lebar Rongga | 2 mm | 6 mm |

| Batas Jarak Dari Tepi | 2 mm | – |

| Ukuran Pori Adsorpsi | 0,5 mm | – |

| Panjang Void | – | 360 mm |

*Keakuratan spesifik perlu ditentukan berdasarkan bahan produk, bentuk, dan persyaratan proses aktual.

Parameter dan Pemilihan Material Lengan yang Disesuaikan

| Barang | Satuan | Zirkonia |

| Kepadatan | gram/cm3 | 6.0 |

| Kandungan Zirkonia | % | 94.4% |

| Ukuran Butir | µm | 0.5 |

| Kekerasan Rockwell (45N) | R45N | 78 |

| Kekerasan Vickers (Beban 500g) | GPa (Kg/mm2 ) | 11.5 (1175) |

| Kekuatan Lentur (20℃) | MPa | 800 |

| Kekuatan Tekan (20℃) | MPa | 2000 |

| Ketahanan Retak (20℃) | MPAM (Malaysia)1/2 | 9.0 |

| Konduktivitas Termal (20℃-400℃) | W /(mk) | 2.5 |

| Koefisien Ekspansi Termal | 10-6 /℃ | 9.6 |

| Tahan terhadap Guncangan Termal | △T℃ | 250 |

| Milik | Satuan | Bahasa Inggris2HAI3 99.7 | Bahasa Inggris2HAI3 99.5 | Bahasa Inggris2HAI3 99 | Bahasa Inggris2HAI3 95 |

| Kemurnian | — | 99.7% | 99.5% | 99% | 95% |

| Kepadatan | gram/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| Kekuatan Tekuk | MPa | 375 | 370 | 340 | 304 |

| Kekuatan Kompresi | MPa | 2450 | 2300 | 2250 | 1910 |

| Modulus Elastisitas | IPK | 380 | 370 | 330 | 330 |

| Ketahanan Retak | MPAM (Malaysia)1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| Kekerasan | SDM | 91 | 91 | 90 | 89 |

| Kekerasan Vickers | Bahasa Indonesia: HV1 | 1600 | 1550 | 1450 | 1400 |

| Koefisien Ekspansi Termal | 10- 6 Bahasa Inggris: K-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| Konduktivitas Termal | Dengan/mk | 32 | 32 | 25 | 25 |

| Stabilitas Kejutan Termal | △T.℃ | 220 | 220 | 200 | 200 |

| Suhu Operasional Maksimum | ℃ | 1750 | 1750 | 1700 | 1500 |

| Resistensi volume pada 20℃ | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| Kekuatan Dielektrik | KV/mm | 22 | 20 | 16 | 15 |

| Konstanta Dielektrik (suhu ruangan) | / | 10 | 11 | 11.5 | 11 |

| Faktor Kerugian Dielektrik MHz | warna coklat muda | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

| Barang | Satuan | Silikon Nitrida |

| Kepadatan | gram/cm3 | >3.2 |

| Kekerasan | – | HRA90 |

| Kekerasan Vickers (Hv50) | HV0,5 | >1550 |

| Modulus Elastisitas | IPK | 290 |

| Kekuatan Lentur | MPa | >600 |

| Kekuatan Kompresi | MPa | 2500 |

| Ketahanan Retak | MPAM (Malaysia)1/2 | > 6.0 |

| Suhu Penggunaan Maksimum | ℃ | 1200 |

| Konduktivitas Termal | W / (P·K) | 15-20 |

| Koefisien Ekspansi Termal | 10-6/℃ | >3.1 |

| Tahan terhadap Guncangan Termal | △T℃ | 500 |

| Kapasitas Panas Spesifik | J/kg·K | 700 |

| Kekuatan Dielektrik | KV/mm | 1 |

| Konstanta Dielektrik | lebih | – |

| Resistivitas Volume pada 20℃ | Ω (satuan cm) | 1,0×1012 |

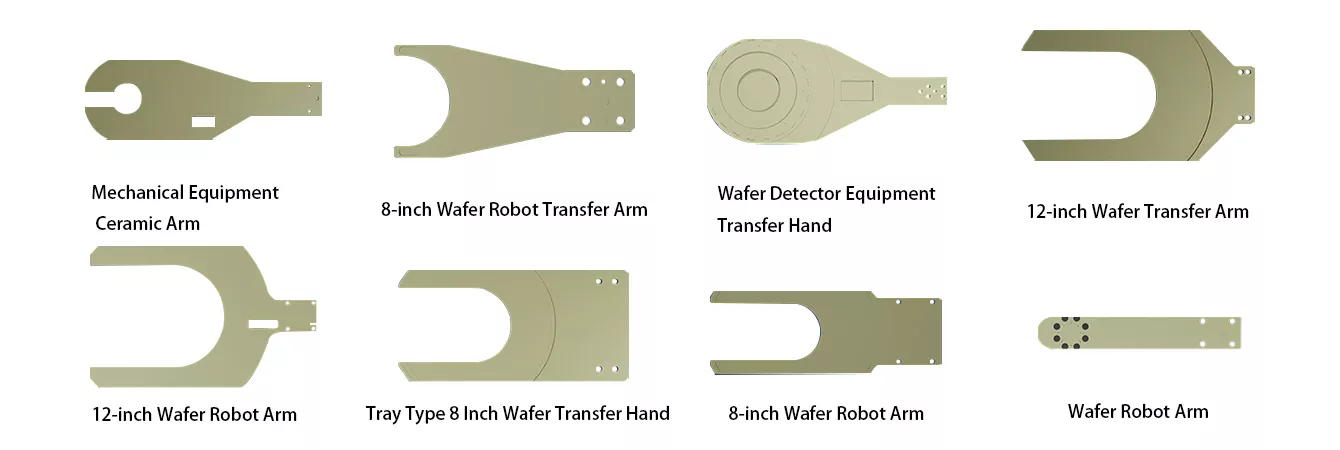

Referensi Ukuran Standar Lengan/Efektor Ujung Keramik

Lengan/efektor ujung keramik adalah komponen kunci yang digunakan untuk menangani wafer dalam manufaktur semikonduktor. Kami dapat menyesuaikannya berdasarkan ukuran wafer, jenis peralatan, dan persyaratan proses. Berikut beberapa ukuran standar umum lengan keramik untuk referensi Anda!

Pilih Panjang Lengan Keramik Sesuai dengan Wafer:

❇️Wafer 6 inci (150mm)Panjang lengan: sekitar 200-250 mm

❇️Wafer 8 inci (200mm)Panjang lengan: sekitar 250-300 mm

❇️Wafer 12 inci (300mm)Panjang lengan: sekitar 350-400 mm

❇️Wafer 18 inci (450mm)Panjang lengan: sekitar 500-550 mm

Lebar dan Ketebalan Lengan Keramik

❇️Lebar: Khas 20-50 mm, tergantung pada ukuran wafer dan kapasitas beban lengan yang dibutuhkan.

❇️Ketebalan: Khas 5-15 mm, untuk memastikan kekuatan dan kekakuan yang memadai serta mengurangi berat.

Desain Ujung Lengan

❇️Desain garpu: umumnya digunakan untuk menangani wafer, lebar dan jarak garpu sesuai dengan slot kotak wafer

❇️Desain cangkir hisap vakum: dapat langsung menyerap wafer, ukuran cangkir hisap umum adalah 10-20 mm

❇️Desain penjepit tepi: digunakan untuk proses khusus, lebar area penjepit adalah 5-10 mm

Apa Kegunaan Lengan Keramik?

Lengan Robot Industri

Lengan keramik digunakan dalam robot industri berpresisi tinggi, tahan aus, dan tahan korosi, dan dapat bekerja secara stabil dalam beberapa pemrosesan presisi dan lingkungan suhu tinggi.

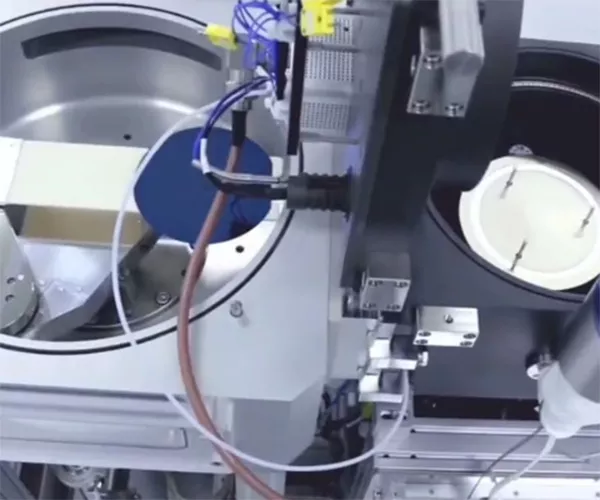

Pembuatan Semikonduktor

Dalam proses pembuatan chip, wafer silikon perlu ditransfer antar tahapan proses yang berbeda (seperti litografi, etsa, deposisi, dsb.), dan lengan keramik dapat bertindak sebagai manipulator penanganan di lingkungan bebas debu.

Manufaktur Elektronik

Lengan keramik untuk manufaktur elektronik cocok untuk proses dengan persyaratan kebersihan tinggi seperti pelapisan vakum, manufaktur chip, dan manufaktur layar OLED. Lengan ini dapat menghindari pengaruh ekspansi termal material logam dan meningkatkan stabilitas.

Riset ilmiah

Pada peralatan laboratorium yang memerlukan ketahanan terhadap korosi dan lingkungan suhu tinggi, lengan keramik dapat digunakan di bidang-bidang seperti sintesis kimia, eksperimen plasma, dan penelitian superkonduktivitas.

Industri Makanan dan Farmasi

Bahan keramik tidak mengandung presipitasi ion logam dan cocok untuk bidang seperti pengolahan makanan dan pengemasan farmasi yang memerlukan kebersihan material yang sangat tinggi.

Layanan manufaktur Lengan Keramik satu atap

15+ Bertahun-tahun Pengalaman. Desain OEM dan Presisi Tinggi. Tim R&D Profesional. Harga Kompetitif.

Apakah lengan keramik/efektor ujung keramik akan aus seiring berjalannya waktu?

Ya, lengan keramik akan aus seiring waktu, terutama di lingkungan yang keras dan kasar. Namun, jangan terlalu khawatir, keramik adalah material yang sangat keras dan tahan lama. Selama dirawat dengan benar, Anda dapat menggunakannya selama bertahun-tahun.

Apa yang menyebabkan lengan keramik patah?

Perubahan suhu yang cepat dapat menyebabkan kejutan termal dan menyebabkan lengan keramik patah. Beban berlebih, benturan, atau benturan keras di luar kapasitas terukur juga dapat menyebabkan pecahnya lengan keramik.

Seberapa sering Anda harus memeriksa lengan keramik Anda?

Inspeksi rutin setiap minggu akan membantu Anda mendeteksi masalah sejak dini. Lengan keramik dapat aus, retak, atau longgar setelah penggunaan jangka panjang. Kami menyarankan Anda untuk melakukan perawatan rutin.