GORGEOUS CERAMICS (GGS) MCH ceramic heaters can save 20%-30% more energy than traditional PTC ceramic heaters.

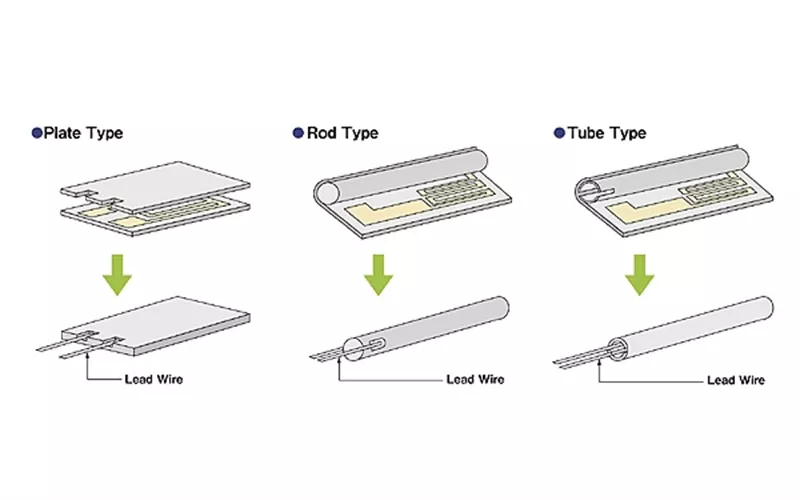

GORGEOUS CERAMICS (GGS) : Manufacturing Processes of Different Shaped Ceramic Heating Elements

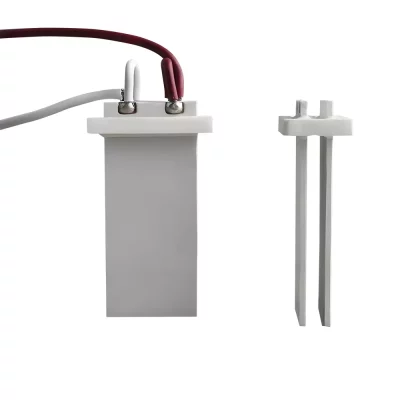

Why choose GORGEOUS CERAMICS (GGS) ? We have a complete one-stop production line (molding → sintering → CNC → assembly), and can customize sizes, shapes, resistance values, and lead types to meet your application needs.

Our products are suitable for applications such as soldering stations, soldering irons, dental floss machines, coffee machines, sensors, home appliances, medical equipment, and industrial heating.

MCH Ceramic Heating Element Characteristics

|

Przedmiot |

Grzejnik glinowy |

|

Max Working Temperature |

1050℃ |

|

Working Temperature |

1050℃ |

|

Przewodność cieplna |

21W/(M·k) |

|

Ciepło właściwe |

0.78×103 J/(kg·k) |

|

Expansion |

0.78×10-6 /℃(40~800℃) |

|

Hardness (load 500g) |

13.5Gpa |

|

Flexural |

320Mpa |

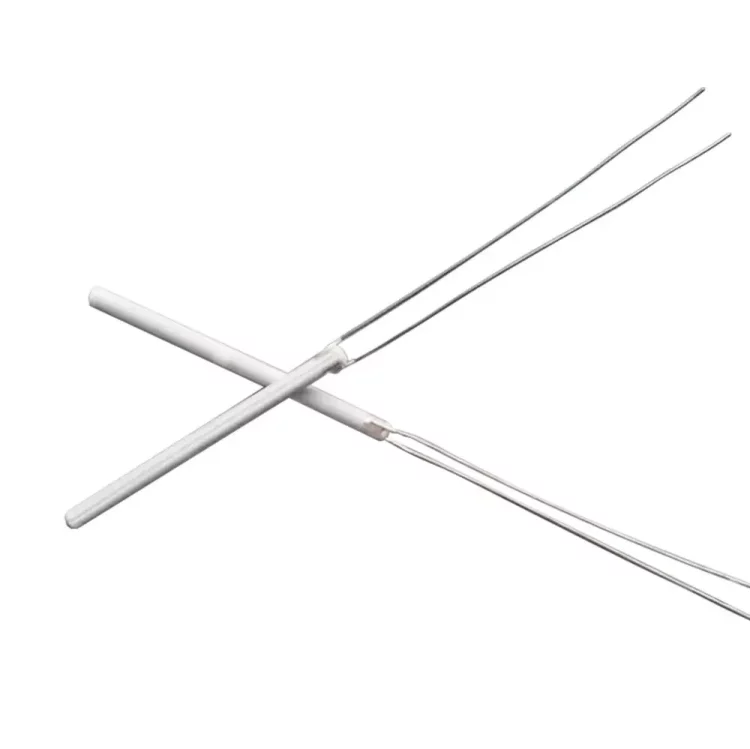

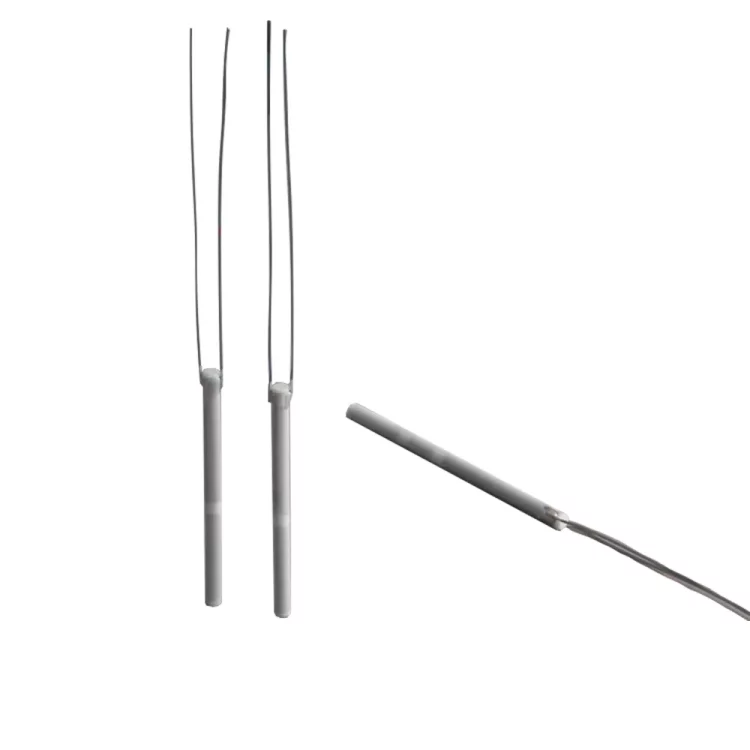

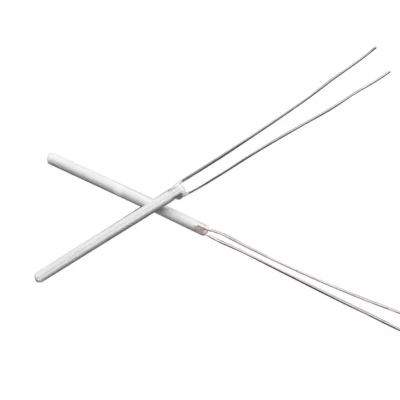

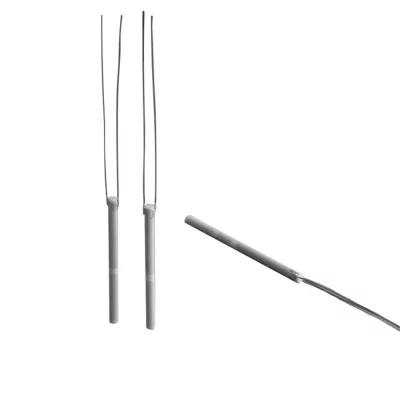

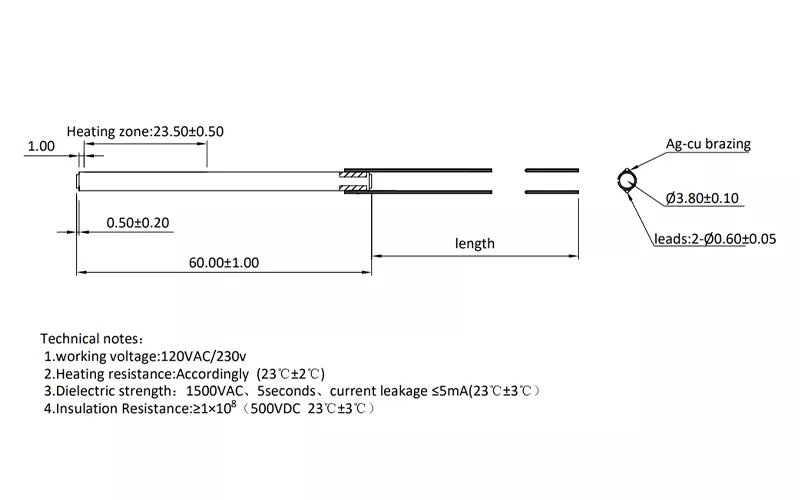

MCH Ceramic Heating Element Parameters

|

Operating Voltage |

12V/24V/120V/230V |

|

Power |

10W-100W |

|

Rozmiar |

Length 60mm * Diameter 3.8mm |

|

Opór |

Corresponding value |

|

Lead |

Two or four nickel wires |

|

Temperatura pracy |

400~500℃ |

|

Insulating Sleeve |

Zgodnie z wymaganiami klienta |

Uses of MCH Ceramic Heating Element

PCB assembly and repair: Can be used for soldering small components, IC rework and pin soldering, repairing broken circuits, etc.

Home appliance repair: Can be used to repair wiring and terminals, switches, heating modules, circuit boards, etc.

Automotive electrical repair: can be used for automotive wiring harness welding, sensor wiring harness repair, etc.