GORGEOUS CERAMICS (GGS) is a manufacturer specializing in the development and production of MCH ceramic heaters for soldering irons and soldering stations. We provide high-performance, customizable solutions tailored to customer needs.

Features of MCH ceramic heaters for soldering irons and soldering stations:

- MCH ceramic heaters are made from 95% Al₂O₃ high-purity alumina ceramic.

- The heating layer is directly printed onto the ceramic sheet and sintered at 1650°C for a one-piece, integrated design. This innovative, environmentally friendly heating element offers uniform heat conduction and a longer lifespan.

- Extremely fast heating: The surface temperature can reach 800°C in just 30 seconds, meeting customer needs for efficient soldering.

- Excellent performance: Stable resistance and silent heating make them suitable for a variety of precision heating scenarios.

- Environmentally friendly and safe: The heater contains no harmful substances and fully complies with international environmental standards.

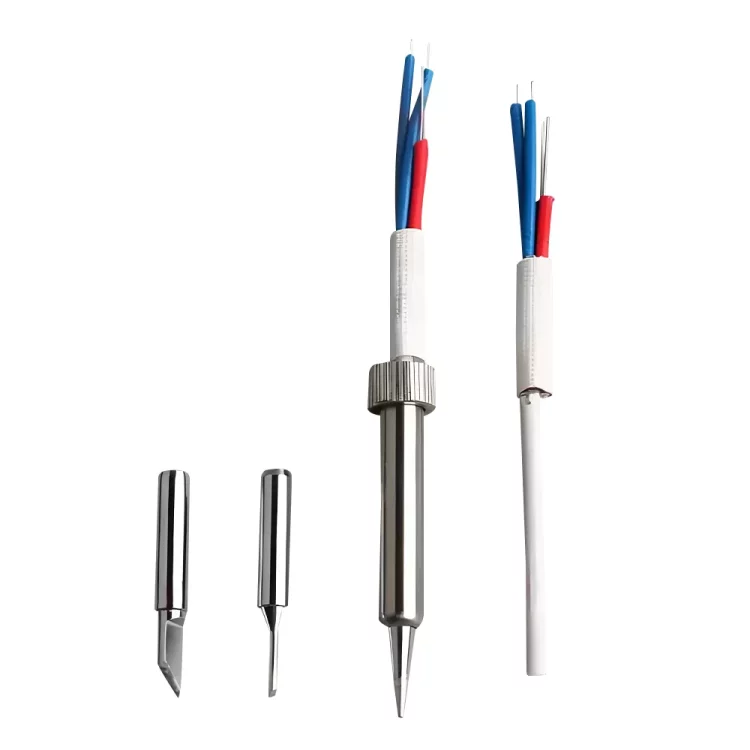

Wide Applications:

GORGEOUS CERAMICS (GGS) customized MCH ceramic heating cores can be used in soldering irons, soldering stations, desoldering stations, and other power tools from globally renowned brands such as HAKKO, WELLER, MILWAUKEE, JBC, and ERSA, meeting the diverse needs of our customers.

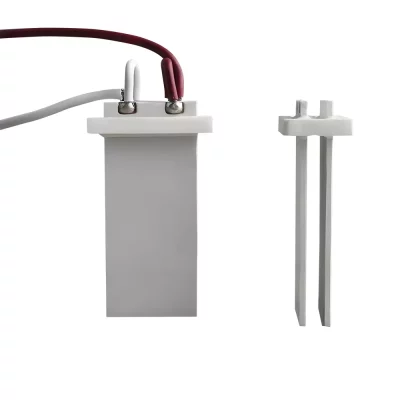

A1321 Ceramic Heating Element Main Materials

Heater body: White alumina ceramic, alumina content not less than 95%.

Nickel wire: N6 nickel wire, 0.6mm diameter.

Brass material: Ag72Cu28

|

Rzeczy |

Inspection conditions |

Jednostka |

Standard |

|

Kolor |

|

|

Biały |

|

Gęstość |

|

g/cm3 |

3.7 |

|

Absorpcja wody |

|

% |

0 |

|

Średnia wielkość ziarna |

|

micrometer |

3~5 |

|

Twardość |

Load 4.9N 4.9N |

GPa |

≥15 |

|

Wytrzymałość na zginanie |

|

MPa |

≥274 |

|

Współczynnik rozszerzalności liniowej |

20~500℃ |

1×10-6mm/℃ |

6.5~7.5 |

|

20~800℃ |

6.5~8.0 |

||

|

Przewodność cieplna |

20℃ |

Watt/(m·K) |

≥20.9 |

|

Specific heat |

|

kJ/(kg·K) |

≥0.8 |

|

Wytrzymałość dielektryczna |

|

kV/mm |

≥12 |

|

Rezystywność objętościowa |

20℃ |

Ω·cm |

≥1014 |

|

300℃ |

≥1011 |

||

|

500℃ |

≥109 |

||

|

Stała dielektryczna |

1MHz |

|

9~10 |

|

Tangens strat dielektrycznych |

1MHz |

|

≤3×10.4 |

|

Chropowatość powierzchni |

|

mikrometr |

0.3~0.8 |

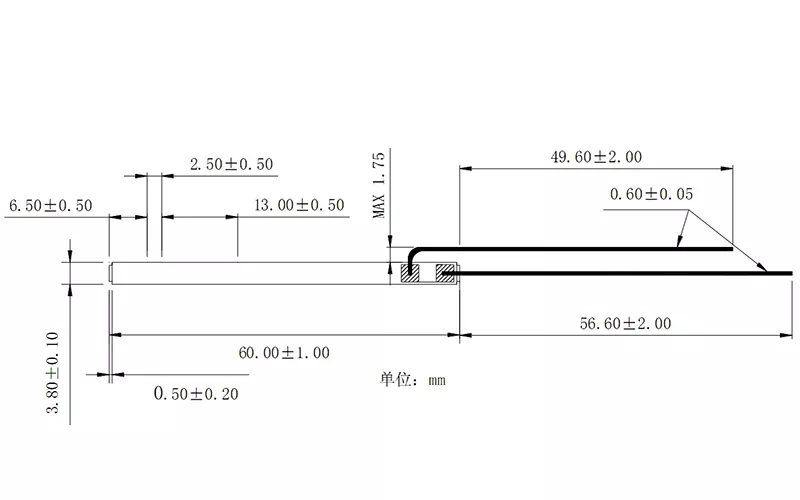

A1321 Ceramic Heating Core Main Parameters

|

Operating voltage |

24V |

|

Working power |

50W+/-10% |

|

Rozmiar |

Length 60mm*diameter 3.8mm |

|

Heating resistor |

3 Ω+/- 10% |

|

Feedback resistor |

50Ω+/-10% |

|

Aplikacja |

HAKKO 936 soldering station |

|

Nickel wire |

Nickel wire |

|

Temperatura pracy |

400~500℃ |

|

Insulation sleeve |

According to customer needs |

Detailed Dimensions of A1321 Ceramic Heating Rod