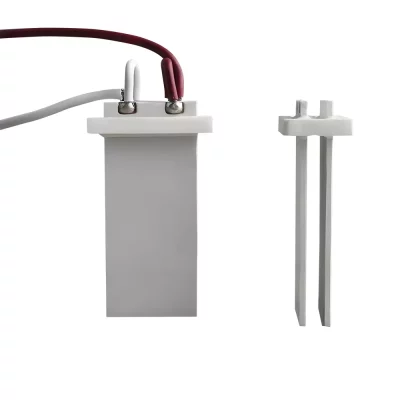

GORGEOUS CERAMICS (GGS) soldering station heating elements are developed based on ceramic lamination technology. Our products are specifically designed for heating applications such as soldering irons, gas appliances, pellet burners, and water heating.

Ceramic Heating Element Processing Technology

The manufacturing process of GORGEOUS CERAMICS (GGS) MCH (Metal-in-One) ceramic heating elements is roughly as follows:

First, according to the predetermined circuit design, a high-melting-point metal paste (such as tungsten paste or molybdenum-manganese paste) is uniformly coated onto an alumina (Al₂O₃) green body, and a layer of sintering aid is then added.

The coating and layering steps are then repeated to construct a multi-layered circuit structure.

After lamination, the entire assembly is sintered in a hydrogen atmosphere at approximately 1600°C to ensure a strong bond between the ceramic body and the metal circuitry.

After sintering, nickel leads are brazed to metal terminals at approximately 800°C, and an external polytetrafluoroethylene (PTFE) insulating sleeve is added to form a complete MCH heating element.

GORGEOUS CERAMICS (GGS) employs a “one-piece ceramic structure” sintering method, which ensures that the internal metal heating circuitry of the heater is completely encapsulated within the ceramic body, effectively avoiding adverse factors such as oxidation.

Applications of Ceramic Heating Elements for Soldering Stations/Irons

GORGEOUS CERAMICS (GGS) ceramic heating elements offer advantages such as rapid heating, high thermal efficiency, high temperature resistance, stable insulation, and long lifespan, making them suitable for applications in electronics, home appliances, industry, and medical fields.

Our products possess exceptional thermal response capabilities and are core components in various rapid heating devices. GORGEOUS CERAMICS (GGS) accepts customization requests and can create customized heating application solutions for you.

Electronics and Personal Devices

- Soldering Stations & Irons

- Electronic Cigarettes & Atomizers

- Hair Straighteners & Curling Irons

Home Appliances and Household Equipment

- Coffee Machine

- Smart Toilet

- Instant Hot Water Kettle, Instant Water Heater

Industrial & Automotive

- Automotive Exhaust Oxide Sensor

- Industrial Equipment Heating Module

- Mold Heater

Sprzęt medyczny

- Medical Equipment Heaters

Other small household appliances

- Air heaters, etc.

Specifications of Welding Station Heating Elements

|

Configuration and Dimension |

|||||||

|

Kształt |

Wymiar |

Tolerancja |

|

Tolerancja |

|

Tolerancja |

Opór Tolerancja |

|

Płyta |

Length(mm) |

|

Width(mm) |

|

Thickness(mm) |

|

|

|

|

10~120 |

①≤20+/-0.3 ②≥20+/-1 |

2~60 |

①≤20+/-0.3②≥20+/-1 |

0.55~2.0 |

①≤1+/-0.1 ②≥1+/-0.15 |

+/-10% |

|

|

length |

|

Średnica |

|

|

|

|

|

Pręt |

8~121 |

①≥30mm:+/-0.5 ②30~100mm:+/-1.0 ③≤100mm~:+/-1.5 |

2.5~8 |

①≥5mm:+/-0.1 ②5~9mm:+/-0.2 ③≤9mm~:+/-0.3 |

|

|

+/-10% |

|

Rura |

8~121 |

2.5~20 |

|

|

+/-10% |

||