GORGEOUS CERAMICS (GGS) is a high-tech enterprise integrating product development, production, and sales. We specialize in producing MCH alumina ceramic heating elements and various other ceramic components.

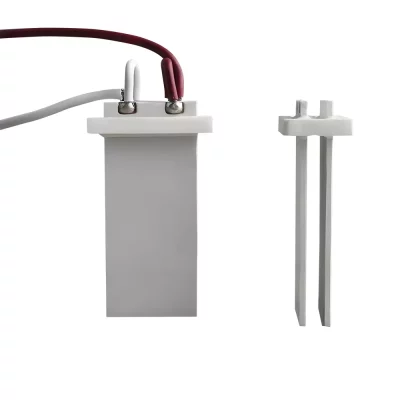

Our MCH alumina ceramic heating elements are compact, powerful, and heat up quickly. They offer higher reliability than PTC heating elements and can be used in the automotive, electronic soldering station, medical, and semiconductor industries.

100W Soldering Iron Ceramic Heater Process Flow

GORGEOUS CERAMICS (GGS) applies a high-melting-point metal (tungsten or molybdenum-manganese) slurry onto an Al₂O₃ casting block according to the circuit design, followed by a layer of sintering additive.

This process is repeated to build multiple layers, which are then sintered together in a hydrogen atmosphere at 1600°C.

Finally, nickel leads are brazed to the metal ends at 800°C, and a PTFE sleeve is fitted to form the MCH heating element.

This process, sintering into a one-piece ceramic structure, effectively prevents oxidation of the internal heating element.

Alumina Heating Element Parameters

|

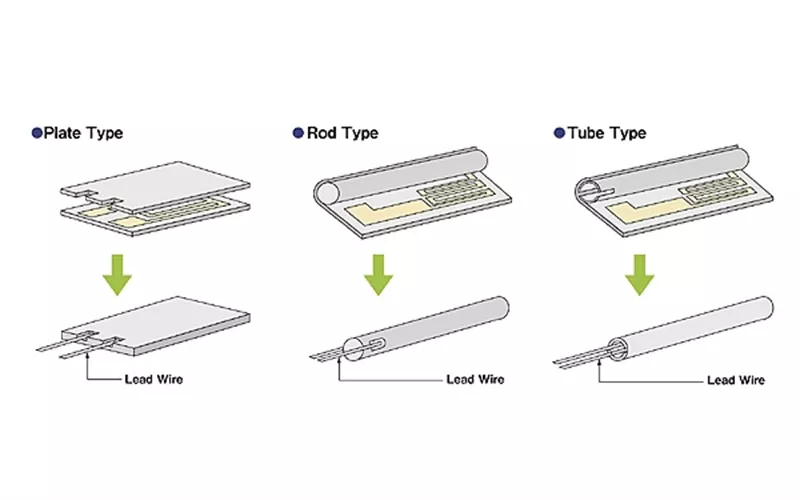

Configuration and Dimension |

|||||||

|

Kształt |

Wymiar |

Tolerancja |

|

Tolerancja |

|

Tolerancja |

Opór Tolerancja |

|

Płyta |

Length(mm) |

|

Width(mm) |

|

Thickness(mm) |

|

|

|

|

10~120 |

①≤20+/-0.3 ②≥20+/-1 |

2~60 |

①≤20+/-0.3 ②≥20+/-1 |

|

①≤1+/-0.1 ②≥1+/-0.15 |

+/-10% |

|

|

length |

|

Średnica |

|

|

|

|

|

Pręt |

8~121 |

①≥30mm:+/-0.5 ②30~100mm:+/-1.0 ③≤100mm~:+/-1.5 |

2.5~8 |

①≥5mm:+/-0.1 ②5~9mm:+/-0.2 ③≤9mm~:+/-0.3 |

|

|

+/-10% |

|

Rura |

8~121 |

2.5~20 |

|

|

+/-10% |

||