고객님께 특별한 사이즈와 형태의 맞춤형 서비스를 제공하고 일괄 색상 차이 문제를 해결하는 세라믹 암 공급업체로서 최선을 다하고 있습니다!

세라믹 암/세라믹 엔드 이펙터 공급업체

세라믹을 맞춤 설정하세요

세라믹 암 설명

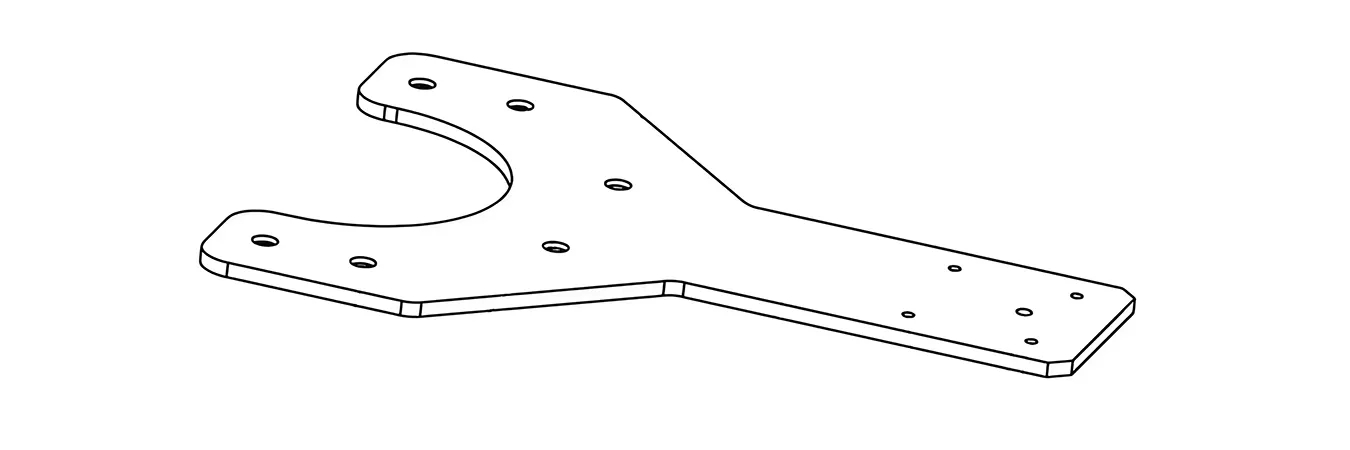

세라믹 로봇 팔, 또한 ~로 알려짐 세라믹 로봇 손가락, 웨이퍼 트레이, 라운드 웨이퍼 로봇 팔등은 주로 반도체 장비의 운송 및 취급에 사용되며, 웨이퍼 실리콘 웨이퍼를 지정된 장소로 배송하는 역할을 담당합니다.

아름다운 제품 특징:

▫️높은 제품 정밀도

▫️우수한 기밀성

▫️고온 저항성이 우수함

▫️제어 가능한 표면 저항률

▫️강력한 산, 알칼리 저항성 및 내식성으로 다양한 극한 환경에 적응 가능

🔷자체 기밀성 테스트: turn off the vacuum air source, negative pressure –85Kpa 에게 -80Kpa, 이상 60년대

🔷웨이퍼 흡착 테스트: 진공 공기 공급원을 끄고 음압을 유지하세요 -80Kpa 에게 -25Kpa, 이상 35초

제조 및 배송 시간 보장

GORGEOUS는 반도체 웨이퍼 가공용 세라믹 분야의 선도적인 제조업체입니다. 15 첨단 세라믹 제조 분야에서 다년간 축적된 기술력과 경험을 바탕으로, 반도체 세라믹 제조 공정을 지속적으로 최적화하고 업그레이드하고 있습니다. 세라믹 암, 로봇 엔드 이펙터, 세라믹 웨이퍼 척 등 다양한 부품을 고객 맞춤형으로 제작해 드립니다.

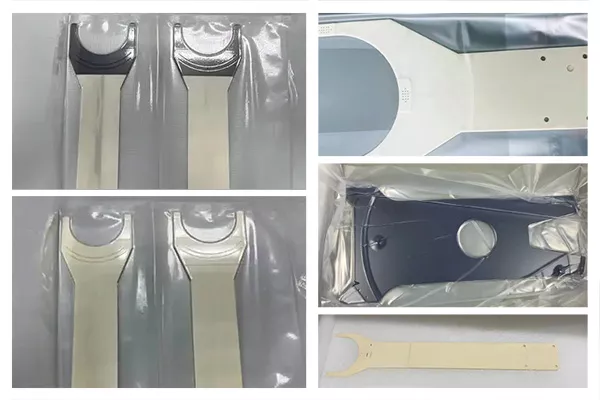

세라믹 암의 포장은 귀하의 요구 사항에 따라 딱딱하고 환경 친화적인 소재나 부드러운 폼 보호재를 사용하여 포장할 수 있습니다.

저희 도자기는 전 세계로 배송되며, 도자기 운송은 고객님의 위치에 따라 달라질 수 있습니다. 고객님의 계획에 따라 신속하게 제작하고 최적의 운송 방법을 선택해 드리겠습니다. 북미에서 가장 빠른 항공화물이 7일 만에 도착합니다.

GORGEOUS는 다음을 포함한 여러 주요 물류 회사와 협력하기로 결정했습니다.

- MSC(지중해 해운 회사)

- 메르스크

- CMA CGM

- 코스코

- 하파그로이드

- DHL

- UPS

- 페덱스

- 티엔티

저희는 여러 화물 운송업체와 협력하여 더 낮은 가격으로 효율적인 배송 옵션을 보장합니다. 정시 배달, 그리고 숨은 비용 없음!

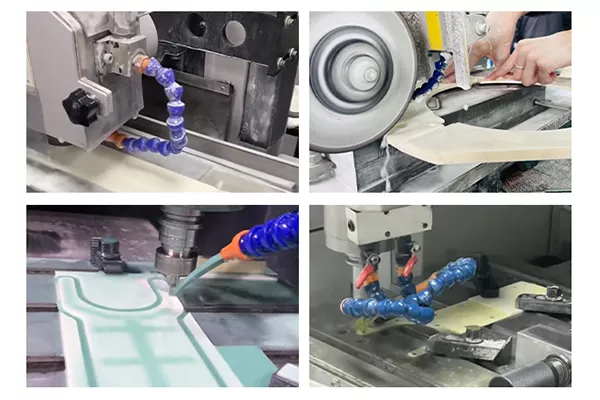

조작

포장

로딩 중

운송

세라믹 암/세라믹 엔드 이펙터의 주요 성능

가벼움

내마모성

부식 방지

고온 저항성

강력한 단열성

멋진 맞춤형 제품 정확도 참조

| 최저한의 | 최고 | |

| 전체 두께 | 1.5mm | 4mm |

| 캐비티 두께 | 0.5mm | 0.7mm |

| 캐비티와 표면 사이의 틈의 두께 | 0.5mm | – |

| 공동의 너비 | 2mm | 6mm |

| 가장자리로부터의 거리 제한 | 2mm | – |

| 흡착 기공 크기 | 0.5mm | – |

| 공극 길이 | – | 360mm |

*구체적인 정확도는 실제 제품 소재, 모양 및 공정 요구 사항에 따라 결정되어야 합니다.

맞춤형 팔 소재 매개변수 및 선택

| 목 | 단위 | 지르코니아 |

| 밀도 | g/cm3 | 6.0 |

| 지르코니아 함량 | % | 94.4% |

| 입자 크기 | 마이크로미터 | 0.5 |

| 록웰 경도(45N) | R45N | 78 |

| 비커스 경도(하중 500g) | GPa(kg/mm2 ) | 11.5(1175) |

| 굽힘강도(20℃) | 엠파 | 800 |

| 압축강도(20℃) | 엠파 | 2000 |

| 파괴인성(20℃) | 엠팜1/2 | 9.0 |

| 열전도도(20℃-400℃) | W /(mk) | 2.5 |

| 열팽창 계수 | 10-6 /℃ | 9.6 |

| 열충격 저항성 | △T℃ | 250 |

| 재산 | 단위 | 알2영형3 99.7 | 알2영형3 99.5 | 알2영형3 99 | 알2영형3 95 |

| 청정 | — | 99.7% | 99.5% | 99% | 95% |

| 밀도 | g/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| 굽힘 강도 | 엠파 | 375 | 370 | 340 | 304 |

| 압축 강도 | 엠파 | 2450 | 2300 | 2250 | 1910 |

| 탄성계수 | 학점 | 380 | 370 | 330 | 330 |

| 파괴인성 | 엠팜1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| 경도 | 인사부 | 91 | 91 | 90 | 89 |

| 비커스 경도 | HV1 | 1600 | 1550 | 1450 | 1400 |

| 열팽창 계수 | 10- 6 케이-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| 열전도도 | W/mk | 32 | 32 | 25 | 25 |

| 열충격 안정성 | △T.℃ | 220 | 220 | 200 | 200 |

| 최대 작동 온도 | 섭씨 | 1750 | 1750 | 1700 | 1500 |

| 20℃에서의 체적 저항 | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| 유전 강도 | 케이볼트/mm | 22 | 20 | 16 | 15 |

| 유전율(실온) | / | 10 | 11 | 11.5 | 11 |

| MHz 유전 손실 계수 | 탄젠트 δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

| 목 | 단위 | 질화규소 |

| 밀도 | g/cm3 | 3.2 |

| 경도 | – | HRA90 |

| 비커스 경도(Hv50) | HV0.5 | 1550년 |

| 탄성계수 | 학점 | 290 |

| 굽힘 강도 | 엠파 | 600개 |

| 압축 강도 | 엠파 | 2500 |

| 파괴인성 | 엠팜1/2 | 6.0 |

| 최대 사용 온도 | 섭씨 | 1200 |

| 열전도도 | W /(M·K) | 15-20 |

| 열팽창 계수 | 10-6/℃ | 3.1 |

| 열충격 저항성 | △T℃ | 500 |

| 비열 | 킬로줄/kg·K | 700 |

| 유전 강도 | 케이볼트/mm | 1 |

| 유전율 | 에르 | – |

| 20℃에서의 체적 저항률 | Ω.cm | 1.0×1012 |

세라믹 암/엔드 이펙터 표준 크기 참조

세라믹 암/엔드 이펙터 반도체 제조 공정에서 웨이퍼를 처리하는 데 사용되는 핵심 부품입니다. 웨이퍼 크기, 장비 종류, 공정 요건에 따라 맞춤 제작이 가능합니다. 참고하실 수 있도록 일반적인 세라믹 암의 표준 크기를 몇 가지 소개합니다!

웨이퍼에 따라 세라믹 암의 길이를 선택하세요:

❇️6인치 웨이퍼(150mm): 팔 길이 : 약 200~250mm

❇️8인치 웨이퍼(200mm): 팔 길이 : 약 250~300mm

❇️12인치 웨이퍼(300mm): 팔 길이 : 약 350-400mm

❇️18인치 웨이퍼(450mm): 팔 길이 : 약 500-550mm

세라믹 암 폭 및 두께

❇️너비: 일반적으로 20~50mm웨이퍼 크기와 필요한 암 부하 용량에 따라 달라집니다.

❇️두께: 일반적으로 5-15mm, 적절한 강도와 강성을 보장하고 무게를 줄입니다.

암 엔드 디자인

❇️포크 디자인: 웨이퍼 취급에 일반적으로 사용되며 포크의 너비와 간격은 웨이퍼 상자의 슬롯과 일치합니다.

❇️진공 흡입 컵 디자인: 웨이퍼를 직접 흡수할 수 있으며 일반적인 흡입 컵 크기는 다음과 같습니다. 10~20mm

❇️에지 클램핑 디자인: 특수 공정에 사용되며 클램핑 영역 너비는 다음과 같습니다. 5~10mm

세라믹 암의 용도는 무엇인가요?

산업용 로봇 팔

세라믹 암은 고정밀, 내마모성, 내부식성 산업용 로봇에 사용되며 일부 정밀 가공 및 고온 환경에서 안정적으로 작동할 수 있습니다.

반도체 제조

칩 제조 공정에서는 실리콘 웨이퍼를 여러 공정 단계(예: 리소그래피, 에칭, 증착 등)로 옮겨야 하며, 세라믹 암은 먼지가 없는 환경에서 핸들링 조작기 역할을 할 수 있습니다.

전자 제조

전자 제조용 세라믹 암은 진공 코팅, 칩 제조, OLED 디스플레이 제조 등 높은 청정도가 요구되는 공정에 적합합니다. 금속 재료의 열팽창 영향을 피하고 안정성을 향상시킬 수 있습니다.

과학 연구

부식과 고온 환경에 대한 저항성이 요구되는 실험실 장비에서 세라믹 암은 화학 합성, 플라즈마 실험, 초전도 연구 등의 분야에 사용될 수 있습니다.

식품 및 제약 산업

세라믹 소재는 금속 이온 침전을 포함하지 않으며, 매우 높은 재료 청결성이 요구되는 식품 가공 및 제약품 포장과 같은 분야에 적합합니다.

원스톱 세라믹 암 제조 서비스

15+ 다년간의 경험. 고정밀 OEM 설계. 전문 R&D 팀. 경쟁력 있는 가격.

세라믹 암/세라믹 엔드 이펙터는 시간이 지나면 마모되나요?

네, 세라믹 암은 시간이 지남에 따라 마모될 수 있으며, 특히 혹독하고 거친 환경에서는 더욱 그렇습니다. 하지만 너무 걱정하지 마세요. 세라믹은 매우 단단하고 내구성이 뛰어난 소재이므로, 제대로 관리하면 오랫동안 사용할 수 있습니다.

세라믹 팔이 부러지는 원인은 무엇일까요?

급격한 온도 변화는 열 충격을 유발하여 세라믹 암이 파손될 수 있습니다. 정격 용량을 초과하는 과부하, 충돌 또는 심한 충격 또한 파손을 유발할 수 있습니다.

세라믹 암은 얼마나 자주 점검해야 하나요?

매주 자주 점검하면 문제를 조기에 발견할 수 있습니다. 세라믹 암은 장기간 사용 시 마모, 균열 또는 헐거워질 수 있습니다. 정기적인 유지 관리를 권장합니다.