Silicon Nitride Heater Supplier

GORGEOUS is a trusted wholesaler of silicon nitride heaters.

We specialize in heating technologies for various ceramic materials, providing customers with optimal heater solutions.

Silicon Nitride Heater

Silicon nitride heaters have excellent durability at high temperatures. As an internationally leading supplier of ceramic heaters, GORGEOUS has developed and mass-produced silicon nitride heaters. They are mainly used in other industrial markets such as diesel engine cold start auxiliary electric glow plugs, gas furnace igniters, and chip welding machine heaters. In addition, we also provide customized design services.

Silicon Nitride Ceramic Heater Product Display

Silicon Nitride Ceramic Air Heating Element

it withstands 2500V, 50Hz for one minute without breakdown.

Maximum operating temperature: 1200°C.

Specific surface power: 25W/cm², customizable.

Silicon Nitride Ceramic Liquid Heating Element

Maximum operating temperature: 1200°C

High power per unit surface area: up to 25W/cm², customizable

Fast heating

Silicon Nitride Heater

Silicon nitride heating plates, uniform and fast heating, customizable size and power, send an inquiry to get a quote.

Silicon Nitride Ceramic Heater

Silicon Nitride Liquid Heater

Liquid-specific design

Voltage: 220V

Power: 3000W, customizable

Send your request to receive a quote

Air Heating Element Performance and Specifications

(Room Temperature)

| Property & Specification | Valor |

| Density ( g/cm 3 ) | 3.2 ‒ 3.4 |

| Flexural Strength ( MPa ) | 900 |

| Fracture Toughness ( MPa∙m 1/2 ) | 6 ‒ 8 |

| Hardness ( HRA ) | 92 ‒ 94 |

| Thermal Conductivity ( W∙m -1 ∙K -1 ) | 23 ‒ 25 |

| Coefficient of Thermal Expansion ( K -1 ) | 3.1 x 10 -6 |

| Electric Resistivity ( Ω∙cm ) | 10 14 |

| Constante dieléctrica | 6 ‒ 7 |

| Rated Voltage ( V ) | 50 ‒ 250 |

| Power Frequency ( Hz ) | 50 / 60 |

| Rated Power ( Yo ) | 450 ‒ 550 |

Liquid Heating Element Performance and Specifications

(Room Temperature)

| Properties & Specification | Valor |

| Density (g/cm 3 ) | 3.2 ‒ 3.4 |

| Resistencia a la flexión (MPa) | 900 |

| Fracture Toughness (MPa∙m 1/2 ) | 6 ‒ 8 |

| Hardness (HRA) | 92 ‒ 94 |

| Thermal Conductivity (W∙m -1 ∙K -1 ) | 23 ‒ 25 |

|

Coefficient of Thermal Expansion (K -1 ) |

3.1 x 10 -6 |

| Electric Resistivity (Ω∙cm) | 10 14 |

| Constante dieléctrica | 6 ‒ 7 |

| Rated Voltage (V) (50/60Hz) | 110 ‒ 380 |

| Power Frequency (Hz) | 50 / 60 |

| Rated Power (W) | 500 ‒ 3000 |

Why choose Silicon Nitride Heaters from GORGEOUS?

GORGEOUS Silicon Nitride Heater Core Advantages

Fast Heating, High Power Density

Silicon nitride ceramic’s excellent thermal conductivity (approximately 20–30 W/m·K, significantly higher than alumina’s 15–25 W/m·K) allows it to reach operating temperature in a very short time.

Its surface power density can reach 10–20 W/cm², 3–5 times higher than traditional metal heating elements, helping you achieve rapid heating and efficient heat transfer.

Small Size and Compact Structure

For the same heating output, our silicon nitride heaters are 30–50% smaller than traditional metal or alumina heating elements, making them ideal for applications with limited space.

Ultra-Long Service Life

Our heaters can withstand rapid cooling and heating cycles exceeding 500°C without cracking. Their continuous operating life typically exceeds 10,000 hours.

High Insulation and Safety

Silicon nitride boasts an insulation resistance of >10⁷ Ω·cm, maintaining stable insulation performance even at temperatures of 1000°C. The risk of electrical leakage is extremely low, ensuring safe operation.

Can directly heat water, oil, and other liquids.

Can be directly immersed in liquid media such as water, kerosene, and diesel.

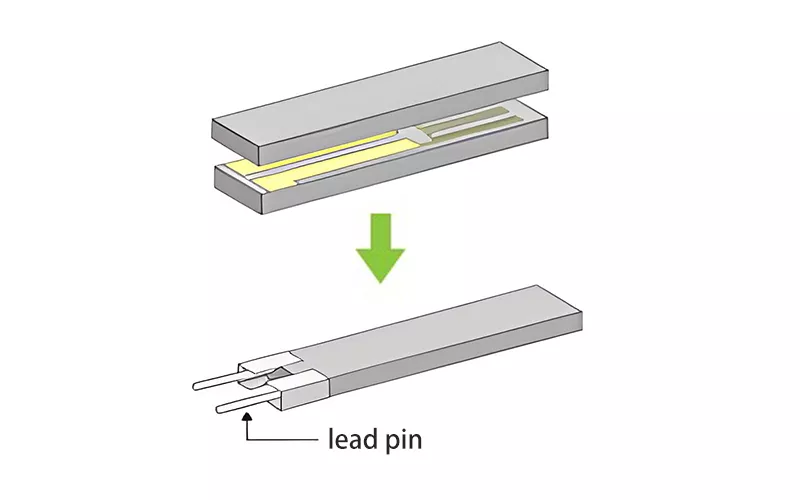

Basic Structure of Silicon Nitride Heater

GORGEOUS’s ceramic heaters feature an integrated heating element design. During the manufacturing process, the heating element is embedded directly into the ceramic substrate and sintered integrally through a high-temperature co-firing process.

The advantages of this integrated structure are as follows:

- Complete isolation from external air—the heating element is encased in dense ceramic, preventing oxidation or moisture from damaging it.

- Multiple circuits can be integrated—multiple circuits can be integrated into the same substrate, enabling flexible output switching.

- Intelligent monitoring—an embedded temperature sensor (such as a thermocouple or PT100) can be used for precise real-time temperature monitoring and closed-loop control.

Silicon Nitride Heating Element Applications

- Internet of Things / 5G

3D glass mold heating

Lens mold heating

Microsensor temperature control

Smart terminal housing thermoforming - Semiconductores

Flip-chip bonder

CVD / PVD chamber heating

Lithography machine temperature control platform - Science / Medicine

Spectrophotometer (FT-IR)

Blood analysis equipment - Economy / Energy

Fuel cells

Gas appliances

Petrochemical equipment

Exhaust gas treatment equipment - Mobility / Transportation

Electric vehicle heating (EV heating)

Glow plugs

Indoor cabin heaters

Gas sensors