GORGEOUS CERAMICS (GGS) is a professional manufacturer and supplier of ceramic heating elements for 3D printers. For over a decade, we have specialized in elemento calefactor solutions. In addition to our existing stock heating elements, we also offer customized heating element solutions and services based on customer drawings or samples, with the assistance of our in-house R&D team, to meet the diverse needs of our customers.

Specifications of Miniature 40-60W Ceramic Heating Elements for 3D Printing

|

Main materials |

Cerámica de alúmina |

|

Solicitud |

E3D printer hot end |

|

Ceramic heating tube shape |

Tube/cup/ring/plate etc. |

|

Operating voltage |

12V or 24V |

|

Working power |

40W-60W-80W |

|

Ceramic heating tube size |

Ready-made models or customized |

|

Temperatura de funcionamiento |

300~500°do |

|

Heating speed (heating element only) |

15 seconds to heat up to 300°do |

What are the Advantages of Ceramic Heating Elements for 3D Printing?

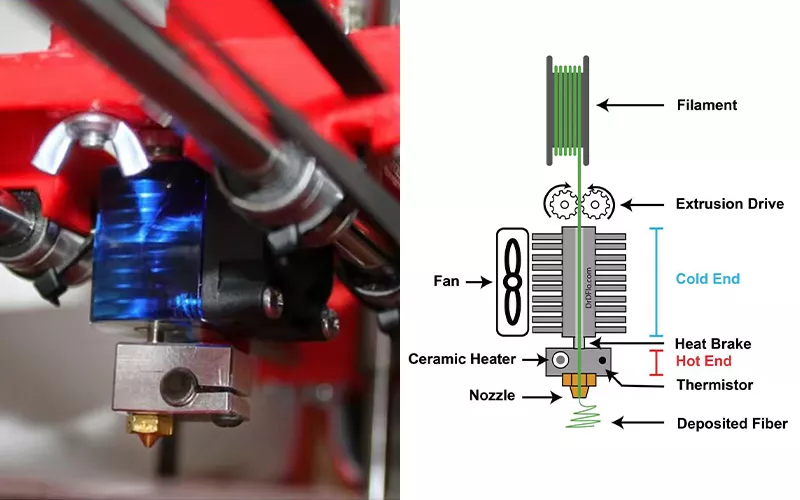

In 3D printing applications, the hot end temperature must be high enough to melt the plastic and extrude it smoothly. This process requires efficient heating elements. Early extruders often used insulated nickel-chromium alloy wire wrapped around the hot end for heating, but this method resulted in uneven heating, depending on the wire wrapping pattern and tightness.

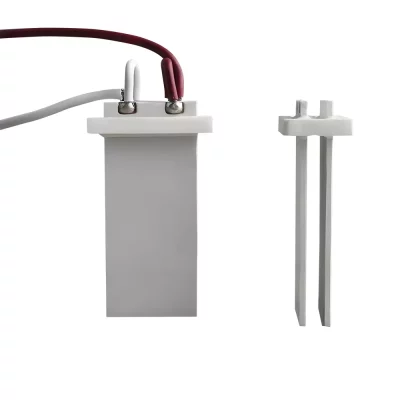

Today, most 3D printers use ceramic heating elements (such as heating tubes and heating rings). These elements consist of a metal sheath containing a resistance wire wrapped around an insulating ceramic core, efficiently converting electrical energy into heat. Compared to traditional heating solutions, ceramic heating elements offer several advantages.

Advantages of GORGEOUS CERAMICS (GGS) Ceramic Heating Elements

Uniform Heating: The ceramic core structure ensures more consistent heat distribution, preventing localized overheating or underheating.

Stable Performance: Ceramic heating elements of the same specification offer predictable heat output, facilitating standardized applications.

Fit-to-Fit: Designed to meet specific application requirements, the cylindrical shape of the ceramic heating tube, for example, allows for precise installation within a hole of a specified diameter, improving heat transfer efficiency.

Adjustable Power: Customizable power options from 25W to 60W are available, or even larger to meet the high-temperature requirements of high-flow extruders.

Compatible: Compatible with a wide range of mainstream 3D printer hot ends, ensuring easy installation.