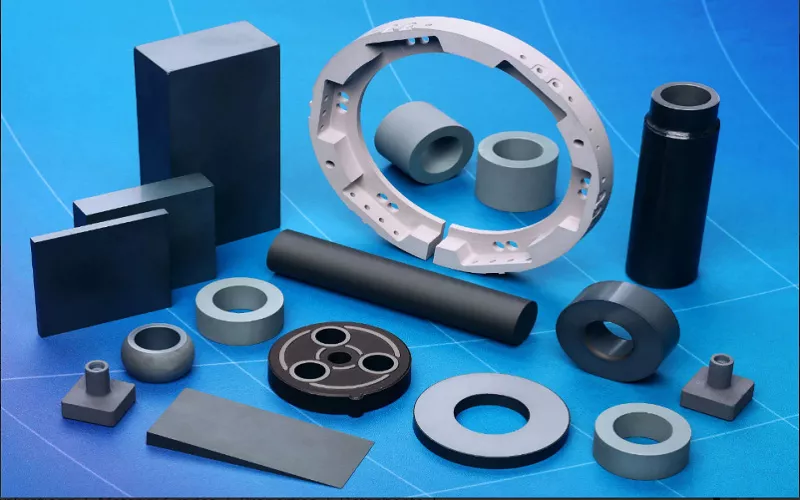

Diagram 1: Hot-surface silicon nitride igniters

Introducción

Hot-surface silicon nitride igniters are a great blend of consistency and reliability in any setting. They have the required modern features that should perfectly sort out your everyday heating needs. Let’s quickly review some of these exciting features together and see how they can benefit you.

Characteristics of Silicon Nitride Ignitors

A nitruro de silicio igniter is a heating device made from Silicon Nitride (Si₃N₄), an advanced ceramic material.

Diagram 2: Silicon Nitride

It has a hot ignition surface that heats up rapidly once plugged to electricity.

Basically, what this ignitor does is to heat your fuel (biomass, wood, pellets) very quickly once electrical power is applied. So, instead of a spark, you will see the surface glow red-hot and ignite the fuel directly. They also resist oxidation.

Silicon nitride igniters stand out for their strength, durability, and consistency. They are not prone to cracking. Instead, they are more impact-resistant and well-suited for repeated heating and cooling cycles.

Their uses cut across several industries and sectors. For instance, many manufacturers use them in gas and industrial furnaces. They are also used for cooking equipment, pellet stoves, and burners, etc.

Now, these are some of the key properties of silicon nitride (Si₃N₄) igniters:

-

Operating temperature: 1,200 - 1,400°C.

-

Heating time: 2 - 5 seconds.

-

Electrical resistivity: 10⁶ - 10⁸ Ω·cm

-

Oxidation resistance: Excellent up to 1,400 °C.

-

Thermal conductivity: 25 - 35 W/m·K.

-

Thermal shock resistance: >500°C temperature change.

-

Flexural strength: 700 - 1,000 MPa.

-

Lifespan: 5 - 10 years (if well maintained).

-

Power consumption: 40 - 90 W (depending on the model).

Also, there are some reasons why silicon nitride igniters are preferred over other types of igniters. They are:

Mechanical toughness - Ability to effectively handle vibration, installation, and thermal cycling. Most times, even better than silicon carbide igniters.

Consistency - They guarantee you a stable electrical resistance over an extended period. They work best in heating systems that cycle on and off many times a day.

How Does a Silicon Nitride Ignitor Work?

Silicon nitride ignitors have a very simple working principle, which is to convert electrical energy into heat. How - Once electricity is turned on, it flows through the silicon nitride ceramic, and resistance is naturally created.

This resistance is due to Si3N4 having a good electrical resistance since it’s a ceramic material. It’s this resistance that causes the ignitor to heat up at a very fast rate. Most times, you’ll see it glowing red-hot within a few seconds.

When it reaches a very high temperature (most likely 1,200°C - 1,300°C), it ignites your fuel. The silicon nitride igniter doesn’t require a spark to ignite fuel; it does this directly.

After your biomass/fuel has been ignited, the ignitor will either switch off or stay warm briefly, depending on its design. This ensures safety and increases the reliability of the device.

Applications of Silicon Nitride Ignitors

The applications of silicon nitride ignitors are very numerous. Let’s explore a few of them:

-

Industrial gas burners –

They are widely used in industrial burners for furnaces and ovens because they can heat up in seconds. Aside from that, they also ignite gas consistently and tolerate continuous high temperatures without cracking.

-

Boilers and water heaters –

In commercial and industrial boilers, silicon nitride ignitors provide dependable startup, especially in systems that cycle on and off frequently.

-

Biomass and pellet stoves –

These ignitors are ideal for biomass systems because they can withstand ash, moisture, and repeated thermal shock.

-

Furnaces and kilns-

High-temperature kilns in ceramics, metal processing, and glass manufacturing rely on them for stable ignition in extreme heat environments.

-

Commercial cooking equipment –

Industrial ovens, fryers, and grills use silicon nitride ignitors for safe, fast ignition without open sparks.

-

In the medical field –

They’re used in high-temperature sterilization and thermal processing equipment. Examples are; autoclaves, incubators, etc. Since most medical procedures sometimes require speed, precision, and stable heat, hot surface Si3N4 ignitors can be helpful.

How To Maintain Silicon Nitride Ignitors

Proper maintenance of your silicon nitride igniter helps you get the best life and performance out of it. Here are some ways you can maintain it:

-

Always protect the igniter surface from water. This is because igniters tend to crack faster when water consistently covers the surface. Also, ensure there is a controlled cool-off, especially when the ignitor’s surface is very hot from long heating periods.

-

Ensure you monitor the ignition resistance at all times - You can do this by using a multimeter to measure the “cold” resistance reading.

Diagram 3: A multimeter for measuring cold

-

Always keep your igniter clean - To maintain the equipment’s efficiency, don’t wait until there is a build-up of ash, soot, or debris before cleaning. Also, ensure you clean the ignitor surface gently and only when it’s cold.

-

Regularly clean up the pathways for airflow to allow for proper heat dissipation.

-

Change damaged cables and exposed wires to avoid accidents like electric shock.

-

Replace or install a new igniter if the heating speed drops significantly or becomes inconsistent.

Silicon Nitride Ceramic Ignitors for Industrial Use

You must understand that selecting the right silicon nitride ceramic igniter goes beyond picking the most expensive ones.

While it all depends on what you want and how the technical specs match your preferred application and environment. Truth remains that there are a few factors you should consider before making your choice. Some of them are:

-

Knowing your operating temperature - if you’re going for industrial operations that demand high-temperature burners or furnaces - Aim for igniters with higher temperature tolerance.

Diagram 4: High Temperature Tolerant Igniters

-

Ensure that it matches your system’s voltage and power requirements.

-

Check the heating speed - Most good industrial Silicon nitride ceramic igniters reach 1,000 °C in 2 - 10 seconds. Go for products with fast response times for operations that demand frequent starts and stops.

-

Evaluate how well the equipment can last you, especially if you intend to use it for industrial purposes.

-

Lastly, look for top suppliers and manufacturers - For your industrial applications, it’s best to buy from suppliers that have customized sizing or voltage options, technical data sheets and support, and reliable warranty

Some recommended ones you can look out for in the market are:

-

Kyocera 230 V Silicon Nitride Igniter Series - Excellent for boilers and industrial furnaces. It also comes with ceramic hot surface igniters with rapid heating and high durability.

-

ATCERA Silicon nitride Ceramic Ignitor - Has a very strong thermal shock resistance and high temperature resistance up to 1,200 °C. You’ll see that it’s widely used in industrial burners and heating equipment.

-

Heat Founder Silicon Nitride Ignitor Series (e.g., HF1205 / HF1211)- Comes with customizable voltage/power ratings (24V, 120V, 230V) and rapid heating up to 1000 °C in a few seconds. They’re specifically designed for pellet stoves, industrial burners, biomass boilers, and other high-temperature ignition systems. They can also offer you longer service life and oxidation resistance.

Preguntas frecuentes

Can a silicon carbide igniter be replaced with a silicon nitride ignitor?

It depends on what you want and the kind of systems you operate. For example, some systems may allow a near-direct or direct replacement. However, you must ensure the electrical ratings match.

Does a silicon nitride igniter consume more electricity?

No. Most of them are designed to be good energy savers by maintaining a stable resistance and faster heat-up time.

Can moist environments affect the performance of a silicon nitride ceramic igniter?

No. This equipment tends to handle moisture better than the traditional ceramic igniters.

Are silicon nitride igniters fragile?

No, they are not. In fact, they’re stronger and tougher compared to older ceramic igniters.

There are various top suppliers of these silicon nitride igniters globally that you can patronise. Here at GORGEOUS CERAMICS(GGS)CERAMICS, we offer the best of these igniters to meet any of your heating needs. Contact us now.

Conclusión

Silicon nitride igniters have significantly changed the face of modern heating. Their mechanical strength, fast heating speed, and durability make them a preferred choice. Whether you’re looking to use them in commercial, residential, or industrial systems, they’re the right and safe choice. You can depend on them anytime, any day!