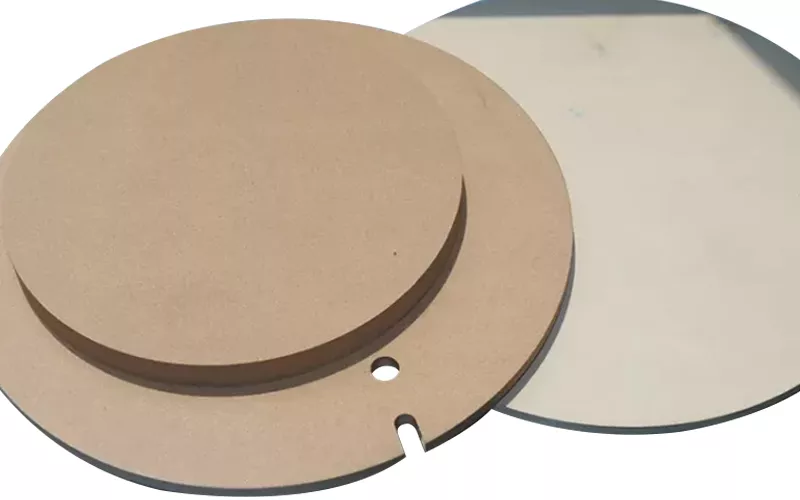

We offer comprehensive custom manufacturing services to produce high-precision, complex parts.

خبرة في تصميم وتطوير حلول السيراميك المتقدمة المخصصة لمختلف التطبيقات.

We have extensive experience in milling, grinding, and polishing high-precision technical ceramics.

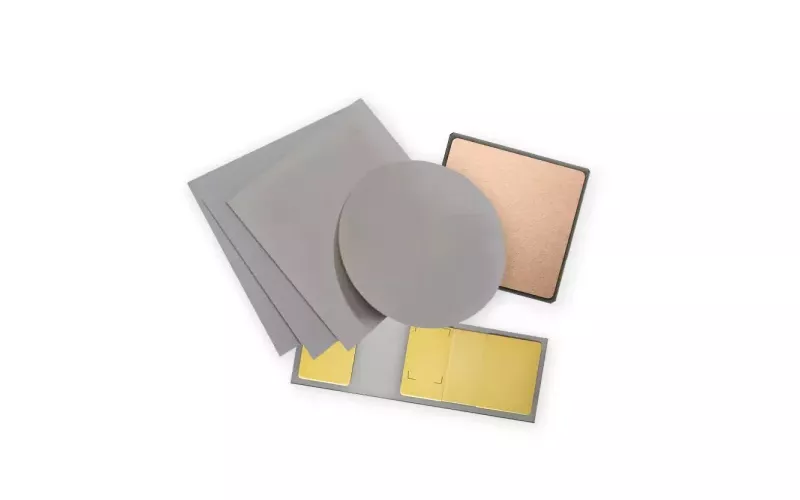

Customizable Ceramic Materials

We offer a wide selection of high-performance ceramic materials, including alumina, zirconium oxide, aluminum nitride, silicon nitride, boron nitride, silicon carbide, boron carbide, and beryllium oxide. GORGEOUS CERAMICS (GGS) will assist you in selecting the most suitable material solution based on your application requirements, achieving the optimal balance between performance and cost.

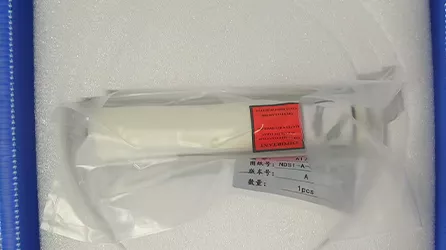

GORGEOUS Best-Selling Products!

We cater to the advanced ceramic needs of various industries. Whether your requirements include standard high-temperature and corrosion-resistant ceramic components, high-precision ceramic parts for the semiconductor industry, or ceramic heaters with fast response and high energy efficiency, we can provide you with proven, high-performance customized solutions, achieving a seamless transition from design to mass production.

Below are some of GORGEOUS CERAMICS (GGS) best-selling products!

سخان سيراميك

مشعل سيراميك

الركيزة الخزفية

سيراميك أشباه الموصلات

Microporous Ceramics

التغذية من خلال

GORGEOUS CERAMICS (GGS)

– Your Trusted Partner

Products sold worldwide

Headquartered in China, GORGEOUS CERAMICS (GGS) exports its advanced ceramic products globally, aiming to provide customers with fast, high-quality, on-demand manufacturing solutions.

As a leading advanced ceramic supplier in China, we support global shipping, delivering to major regions in North America and Europe in as little as 3–10 days.

Our project engineers are all proficient in English communication. On weekdays, we respond quickly, seamlessly connecting with customer needs across time zones and ensuring smooth project progress from prototyping to delivery.

30,000㎡ 20,000+ 120+

Factory floor area Global customers The country of service

From New Product Development to Solutions

GORGEOUS CERAMICS (GGS) offers more than just manufacturing services. We provide full-cycle product development solutions, from design and prototyping to production and packaging.

سيراميك متقدم مخصص لصناعات مختلفة

Our ceramic products have a wide range of applications, including aerospace, automotive, semiconductor electronics, machinery, chemical and medical fields.

الفضاء الجوي

السيارات

الإلكترونيات

الهندسة الميكانيكية

طبي

كيميائي

تطبيقات تصنيع السيراميك لدينا

GORGEOUS CERAMICS (GGS) provides custom ceramic manufacturing to create structures, machines and parts including:

ماذا يقول عملاؤنا

لقد تواصلت شركة GORGEOUS معنا بشكل جيد للغاية، وفهمت احتياجاتنا دائمًا بدقة واستجابت في الوقت المناسب.

كارل

سرعة إنتاجهم مذهلة، يتم تسليم طلباتنا دائمًا في الوقت المحدد، والجودة ممتازة، ومن دواعي سروري العمل معهم.

شي زان

نحن سعداء جدًا بخدمتهم! يقومون بحل أي مشكلة فورًا، مُظهرين احترافية وكفاءة عالية. شكرًا جزيلًا لشركة GGS!

هانز

الموارد ذات الصلة

How Silicon Carbide Works: Material Properties and Applications for Ultra-High Temperature Environments

Most ceramics crack or melt above 1400°C. Silicon carbide keeps working at temperatures up to 1600°C. This guide covers SiC material properties, manufacturing methods, and actual applications in the aerospace, defense and industrial fields. You’ll understand what makes silicon carbide ceramics and how to select suitable materials according to the application. What Is Silicon Carbide Ceramic? Figure 1: Raw Silicon Carbide You get silicon carbide (SiC) when silicon and carbon atoms bond together in a crystal structure. You’ll hear it called an ultra-high temperature ceramic because it works continuously at 1600°C. This temperature is high enough to melt most metals […]

Silicon Carbide Wafers: Properties, Uses & Market

1.What to Expect From Silicon Carbide Wafers in 2026 Silicon carbide (SiC) wafers are soaring in demand in 2026 due to outstanding performance. They offer higher thermal management and efficiency in your high-temperature, high-voltage & frequency electronics than silicon wafers. Thus, your SiC wafers are now preferred in electric vehicles, 5G systems, and renewable energy systems. 2. What Are Silicon Carbide (SiC) Wafers? 2.1 Definition of Silicon Carbide (SiC) Your silicon carbide (SiC) is compound of carbon and silicon. Due to its exceptional hardness, wide bandgap, and resistance to high temperatures and voltages, SiC is preferred for robust electronics. 2.2 […]

Advanced Ceramic Heating Elements: Material Selection & Procurement Guide for 1500°C+ Industrial Applications

Your metal heating elements keep failing above 1300°C. You are wasting money on constant replacements. This guide helps you pick the right ceramic material, silicon carbide, aluminum nitride, alumina, or silicon nitride based on your temperature, budget, and application. You’ll learn specifications, real costs, and selection strategies that save you downtime. What Is an Industrial Heating Element? Precision ceramic coil spacing. Your industrial heating elements convert power to heat by electrical resistance. They power your furnaces, kilns and processing facilities from 600°C to 1850°C. You need advanced ceramics for anything above 1300°C. Metal can’t survive those temperatures. What Materials Are […]

إرسال عرض أسعار سريع

لماذا تحظى شركة GORGEOUS بثقة 1000+ عملاء؟

يُقدم تصنيعنا للسيراميك الصناعي فوائد عديدة لمختلف الصناعات والشركات والمشاريع. إليكم مزايا خدماتنا.

إنتاج سريع وبأسعار معقولة

تتميز شركة GORGEOUS بقدرتها على إنتاج نماذج أولية ومنتجات نهائية متنوعة من السيراميك بسرعة. كما تتميز بسرعة الإنتاج مع ضمان دقة عالية. كما يُمكّننا إنتاجنا واسع النطاق من تقديم خدمات تصنيع سيراميك فعّالة من حيث التكلفة.

نسبة قوة إلى وزن ممتازة

بفضل تقنيات التصنيع المتطورة لدينا، ننتج قطعًا سيراميكية عالية الجودة ومتينة. نضمن قوة تحمل عالية ومقاومة للخدش والتآكل لجميع منتجاتنا السيراميكية.

مجموعة واسعة من المواد والتقنيات المستخدمة

نحن خبراء في تقنيات تصنيع المواد الخزفية المختلفة التي تسمح لنا بإنتاج أجزاء معقدة بميزات معقدة إضافية مثل الشقوق والفتحات والثقوب وما إلى ذلك. كما يمكن لمجموعة واسعة من المواد الخزفية لدينا أن تتحمل أيضًا المقاومة الحرارية ومقاومة التآكل والمزيد.