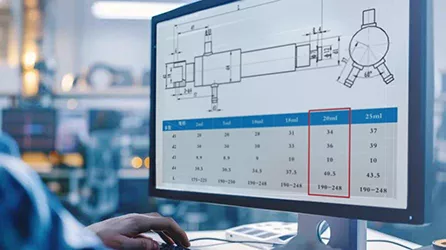

我们提供全面的定制制造服务,生产高精度、复杂零件。

具有为各种应用设计和开发定制先进陶瓷解决方案的经验。

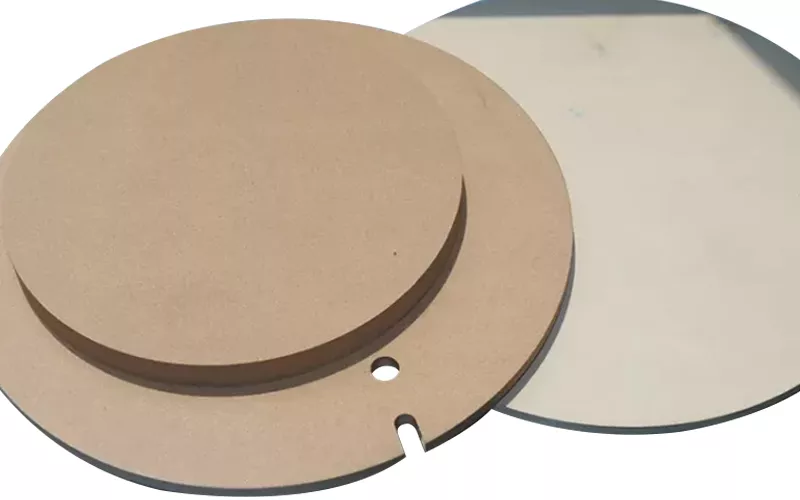

我们在高精度技术陶瓷的铣削、研磨和抛光方面拥有丰富的经验。

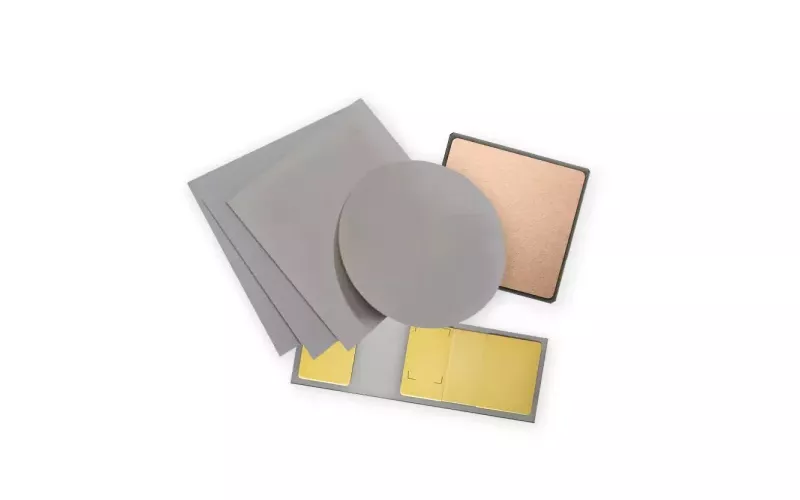

可定制陶瓷材料

我们提供多种高性能陶瓷材料,包括氧化铝、氧化锆、氮化铝、氮化硅、氮化硼、碳化硅、碳化硼和氧化铍。GORGEOUS CERAMICS (GGS) 将根据您的应用需求,协助您选择最合适的材料解决方案,从而在性能和成本之间实现最佳平衡。

GORGEOUS CERAMICS (GGS)的畅销产品!

我们致力于满足各行业对先进陶瓷材料的需求。无论您的需求是标准的高温耐腐蚀陶瓷部件、用于半导体行业的高精度陶瓷零件,还是响应速度快、能效高的陶瓷加热器,我们都能为您提供经过验证的高性能定制解决方案,实现从设计到批量生产的无缝衔接。

以下是 GORGEOUS CERAMICS (GGS) 的一些畅销产品!

陶瓷加热器

陶瓷点火器

陶瓷基板

半导体陶瓷

微孔陶瓷

馈通

GORGEOUS CERAMICS (GGS)

-您值得信赖的合作伙伴

产品销往世界各地

总部位于中国的高丽陶瓷(GGS)向全球出口其先进的陶瓷产品,旨在为客户提供快速、高质量、按需制造的解决方案。

作为中国领先的先进陶瓷供应商,我们支持全球发货,最快可在 3-10 天内将产品运送到北美和欧洲的主要地区。

我们的项目工程师都精通英语沟通。工作日期间,我们响应迅速,能够跨时区与客户需求无缝对接,确保项目从原型设计到最终交付都能顺利进行。

30,000㎡ 20,000+ 120+

Factory floor area Global customers The country of service

从新产品开发到解决方案

GORGEOUS CERAMICS (GGS)提供的不仅仅是制造服务。我们提供全方位的产品开发解决方案,从设计和原型制作到生产和包装,涵盖产品开发的各个环节。

为不同行业定制先进陶瓷

我们的陶瓷产品应用范围广泛,包括航空航天、汽车、半导体电子、机械、化工和医疗等领域。

航天

汽车

电子产品

机械工业

医疗的

化学

我们的陶瓷制造应用

GORGEOUS CERAMICS (GGS) 提供定制陶瓷制造,以制造结构、机器和零件,包括:

我们的客户怎么说

GORGEOUS CERAMICS (GGS)与我们沟通得很好,总是准确地理解我们的需求并及时做出回应。

卡尔

他们的生产速度令人惊叹,我们的订单总是准时交付,质量非常好,与他们合作很愉快。

社赞

我们对他们的服务非常满意!他们能立即解决任何问题,展现出专业和高效的服务。非常感谢 GGS!

汉斯

相关资源

Applications of Silicon Carbide Bearings and Shafts in High-Speed and Wear-Intensive Industries

Standard material-made bearings often fail in harsh chemical, advanced engineering, and fast-moving industries. Rather, silicon carbide bearings perform exceptionally well in these fields.Let’s explor…

Silicon Carbide vs Steel FGD Nozzles: Which Reduces Downtime?

Steel desulfurization nozzles fail in 6-12 months due to wear and clogging. Silicon carbide nozzles last 3-5 years with excellent corrosion resistance. This guide covers performance comparison, total …

Silicon Carbide Bulletproof Plate: Lightweight, Reliable & Safe

Your silicon carbide bulletproof plate offers exceptional hardness, low density, and great shock resistance. In your defense equipment manufacturing, SiC translates to superior, lightweight bulletproo…

提交快速报价

为什么GORGEOUS受到 1000+ 顾客?

我们的工业陶瓷制造服务能为各行各业、企业或项目带来诸多益处。以下是我们服务的优势。

经济实惠且生产速度快

GORGEOUS 能够快速生产各种陶瓷原型和最终产品。GORGEOUS 在确保高精度的同时,还能快速生产。我们的大规模生产也使我们能够提供经济高效的陶瓷制造服务。

出色的强度重量比

我们凭借先进的制造技术,生产出高品质且耐用的陶瓷部件。我们保证所有生产的陶瓷产品均具有高强度、耐刮擦和耐腐蚀的特性。

广泛使用的材料和技术

我们是不同陶瓷材料制造技术的专家,这使我们能够生产具有额外复杂特征(例如凹口、狭槽、孔等)的复杂零件。我们广泛的陶瓷材料还具有耐热性、耐腐蚀性等性能。