In this article, we’ll learn how to best use electric heating tubes in various contexts.

Check in to learn DIY and professional tips for effective usage and maintenance!

How To Use Electric Heating Tubes for Industrial Applications?

1. Set the Right Power-Input Voltage

If your electric heating tube’s components keep failing, start by checking your voltage setting. Then set the power input voltage within 10% of your tube heater’s recommended voltage.

This not only prevents premature failure of delicate components, it saves you from costly component replacements. You also get to avoid unnecessary hazards caused by electric shock.

2. Check the Relative Humidity of the Working Air

Relative humidity is a comparison of the amount of moisture in the air and the full amount of moisture the air could hold at the same temperature. You have the moisture currently in the air versus the air’s full moisture-hold potential.

According to the International Electrotechnical Commission (IEC) standards, the relative humidity should be lower than or equal to 95%. This means that your device won’t come into contact with excess moisture and its adversities.

Some of these adversities include compromised insulation, rust on metallic components, I mold growth.

3. Optimize the Insulation Resistance

Simply ensure your insulation resistance is greater than or equal to 1MΩ and the dielectric strength is 2KV/1min for optimal performance.

4. Air Heating

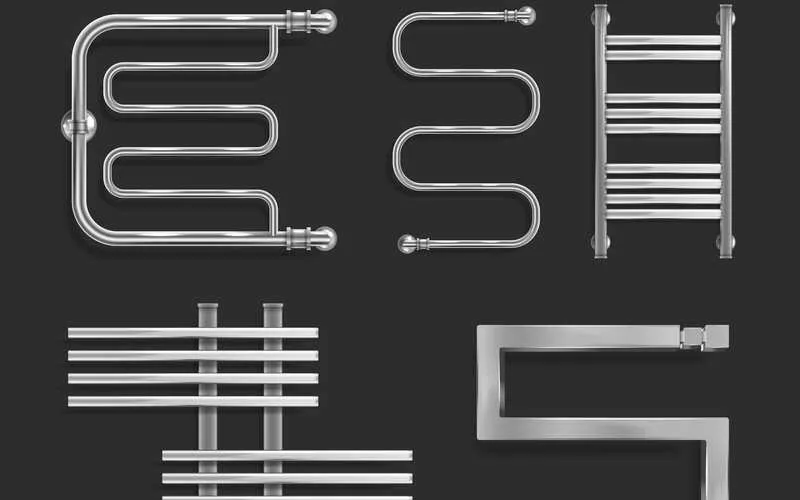

For air heating, positioning the components crosswise will provide just the right heat dissipation conditions. Make sure that the components are evenly placed to provide enough room for heating.

5. Fusible Materials (Nitrates/Wax) Heating

To prevent explosions, lower the voltage setting and ensure the wiring doesn’t come into contact with the fusible material. You also want to keep the wiring dry.

Carry out this procedure in a room with sufficient ventilation, as you direct the heating apparatus away from people. Always fully immerse the heating tube in the fluid, liquid, or solid. Avoid dry heating at all costs.

How to Use Electric Heating Tubes for General Purposes?

https://www.youtube.com/watch?v=ZxSKL02y8rQ&t=613

The following tips apply to the general use of electric heating tubes, whether at home or in an industrial setup.

-

Keep the terminal nuts tight enough (but not too much). Ensure the terminal wiring is clean and dry to avoid short circuits.

-

Once you have unplugged the heat tube, let it cool completely before plugging it back in.

-

Look out for failed components, worn parts, or damaged cords, and replace them accordingly.

-

Keeping the shell grounded effectively prevents fire accidents.

-

For water tank heating, you want to place the heater tube horizontally to enhance quick and uniform heating, rather than placing it vertically.

-

As the main and most common heating tube problem is overheating, take all necessary steps to prevent it.

The life expectancy of all household appliances has either stayed the same or declined in the last decade. Statista.

How the Components of Electric Heating Tubes Work?

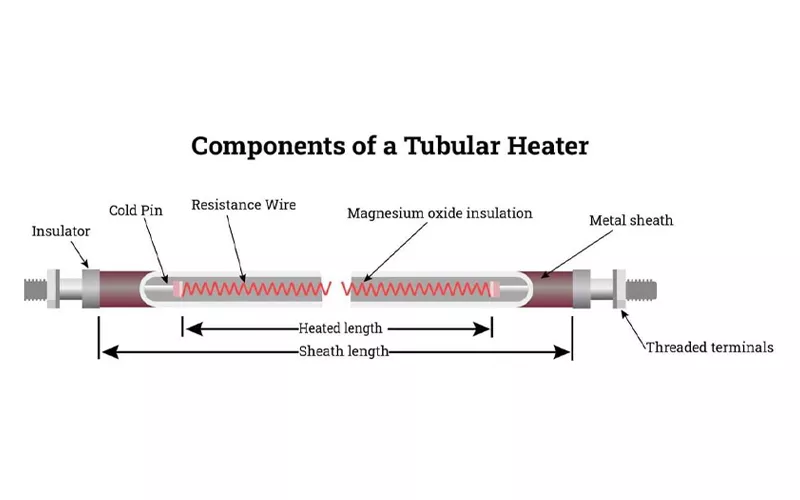

Electric heaters comprise a shell, resistance wire, filler, I a terminal.

The table below shows the different components of heating tubes against their roles in giving optimal performance:

|

Component |

Tworzywo |

Role |

|

Shell |

Copper, stainless steel, or iron |

Forms the outer layer of protection for the inner components |

|

Resistance wire |

Iron-chrome-aluminum or nickel-chromium |

Have high resistance that converts electric energy to heat. They also have a high temperature resistance of 1,200°C |

|

Filler |

Upgraded Magnesia (MgO) powder |

Has impressive thermal conductivity and insulation properties for minimal heat loss |

|

Terminal |

Stainless steel, iron, copper |

Acts as a connection between the resistance wire and the power line |

Why the Material of Electric Heating Tubes Matters?

You might be finding it hard to keep your working air conditions at the right relative humidity. Besides, sometimes exposure of heating tubes to gases or corrosives is inevitable. In such circumstances, the type of material of the device is the determinant for longevity.

You can either get a susceptible component material that easily breaks down or a resilient one that’s designed to withstand harsh conditions.

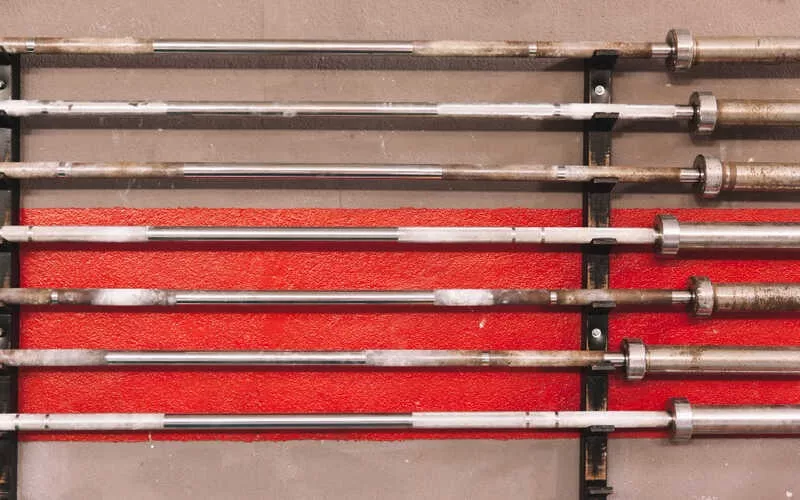

Most heating tube components are mostly metallic (iron, stainless steel, copper). However, you may get alternative tube component materials like ceramics.

Click Tutaj for more information about ceramics as heating elements.

Ceramic Vs. Metallic Heating Components

The table below shows the direct distinction between ceramics and metals as used in electric heating tube components.

|

Nieruchomość |

Metal |

Ceramiczny |

|

Współczynnik rozszerzalności cieplnej |

10–17 x 10⁻⁶/°C |

4–8 x 10⁻⁶/°C |

|

Oxidation rate |

High, hence high material degradation |

Niski |

|

Maximum temperature |

1,200°C |

2,000°C |

|

Korozja |

Prone to chemical degradation |

Resistant to alkali, acids, and fluids |

|

Okres użytkowania |

Up to 5 years |

Up to 15 years |

From the above information, ceramic heating tube components last 3 times longer than their metallic counterparts. Thus, spending a fortune on a product that lives up to its lifespan is better than being frugal for a short service life.

Why Ceramic Heating Tubes are the Future!

Electric heating has undergone an impressive transformation through the breakthrough of advanced ceramics. Now, manufacturers can create any product and customize it with this premium material for a “safety” touch.

Instead of having to worry about how to prevent scalding or how to stay away from corrosives, they curate a resilient material. One that won’t need much nudging to give the desired performance output.

And if you’re a manufacturer looking to venture into electric heating tubes, there’s no better time. The global electric heating tube market is growing exponentially, being driven by a 14.1% CAGR (Compound Annual Growth Rate) from 2025 to 2032.

Wniosek

So far, we hope you have all it takes to get a fit-for-the-job electric heating tube. Remember, good maintenance and frequent inspection will expose any faults and result in optimal heating tube performance. Overall, a good heating tube material is the answer for longevity, especially in harsh working conditions.

Talk to Us!

https://www.youtube.com/watch?v=gGhpDM6uQxQ&t=8s

If you’re looking to optimize your electric heating tube manufacturing with ceramic materials, we’re here to help. Also, feel free to skim through our website for a quick preview of our products.