Podłoże z azotku krzemu

GORGEOUS is a leading international ceramic supplier, specializing in providing customers with one-stop customized solutions for high-quality, high-purity silicon nitride substrates.

High-Quality Silicon Nitride Substrate

- Ultra-High Mechanical Strength: Flexural strength reaches 800–1000 MPa, twice that of alumina and aluminum nitride substrates, effectively preventing cracks and chipping during processing and use.

- Excellent Thermal Conductivity: Thermal conductivity reaches 70–90 W/m·K, approximately three times higher than traditional alumina and ZTA substrates, ensuring rapid heat dissipation from power devices and high-heat-density applications.

- Silicon-Matched Thermal Expansion Coefficient: The coefficient of thermal expansion (CTE) is close to that of silicon, perfectly matching semiconductor chips and reducing the risk of failure caused by thermal stress.

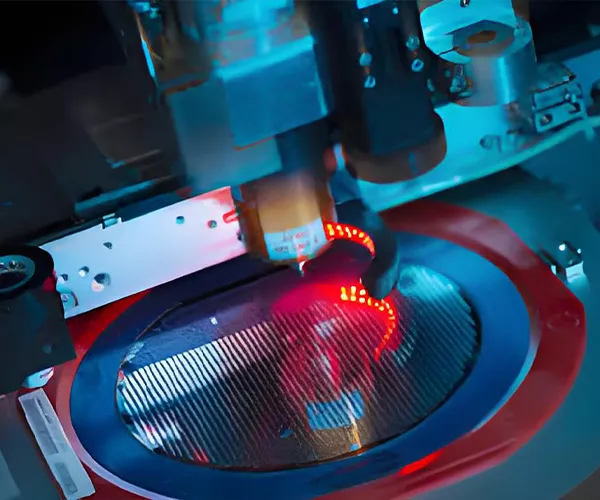

- Diverse Processing Support: We support laser cutting, drilling, polishing, and surface metallization (such as Ag, Au, Cu, and Ni) to meet customers’ diverse packaging and soldering requirements.

- Strict Thickness and Dimensional Tolerances: Thicknesses can reach 0.25–0.635 mm, with a controllable tolerance of ±10%. Customizable dimensions ensure a perfect fit for diverse electronic applications.

- High-quality surface treatment: supports grinding, polishing, and coating, with excellent surface flatness, suitable for high-precision circuit design.

Silicon Nitride Substrate Description

Silicon nitride substrates are ideal for innovative applications such as electric vehicles. GORGEOUS can create ultra-thin substrates with a flexural strength exceeding 700 MPa and a thickness of only 0.25 mm, and can also achieve 1 mm copper metallization.

Silicon nitride substrates coated with copper metallization offer excellent current-carrying and heat-dissipating properties, enabling compact power modules within limited dimensions.

Silicon nitride substrates offer exceptional fracture toughness and insulation properties. When used in applications such as battery-powered electric vehicles, they offer exceptional reliability and longevity, enabling the development of high-power density power modules while maintaining safety.

Silicon nitride substrates are an excellent solution for electric vehicle applications. GORGEOUS has been researching and developing silicon nitride materials for many years and can provide customers with silicon nitride substrates that offer exceptional robustness, superior flexural strength, fracture toughness, and insulation properties, contributing to modern electric vehicle applications.

Provide Customized Services for Silicon Nitride Substrates

Zapewnij klientom rozwiązania dostosowane do ich potrzeb

Silicon Nitride Substrate Parameters

| Właściwości fizyczne | Gęstość | ≥ 3.22 g/cm3 |

| Surface Properties | Ra value | ≤ 0.4 µm |

| Właściwości mechaniczne | Flexural Strength (3-Point Bending, σ₀) | ≥ 700 MPa |

| Fracture Toughness (IF Method) | ≥ 6.5 MPa·√m | |

| Moduł Younga | ≥ 280 GPa | |

| Właściwości termiczne | Coefficient of Thermal Expansion (100–800℃) | ±3.3 × 10⁻⁶/K |

| Specific Heat Capacity at 25 ℃ | ≥ 0.68 J/(g·K) | |

| Thermal Conductivity at 20℃ | 90 W/(m·K) (±10% measurement tolerance) | |

| Właściwości elektryczne | Dielectric Constant (at 1 MHz) | ±7.8 |

| Dielectric Loss Factor (at 1 MHz) | ≤ 3 × 10⁻³ | |

| Volume Resistivity (at 20 ℃) | ≥ 1 × 10¹⁴ Ω·cm | |

| Wytrzymałość dielektryczna | ≥ 25 kV/mm |

Si3N4 Substrate Processing Accuracy

| ltem | Jednostka | Specification |

| Standard Size | inch | 5.5″x 7.5″ |

| Tolerancja | ±1.0%( minimum deviation +0.1 mm) | |

| Grubość | mm | 0.25-0.635 |

| Tolerancja | ±10%( minimum deviation +0.04 mm) | |

| Wypaczenie | mm | 0.002/mm |

Silicon Nitride Substrate Applications

Automotive Electronics

New Energy Vehicle Power Modules: Silicon nitride substrates withstand frequent temperature cycling and vibration shock.

Motor Control Modules: Si3N4 substrates improve the reliability of motor control units.

ADAS Radar Systems: Ensure the stability of electronic components in extreme environments.

Elektronika mocy

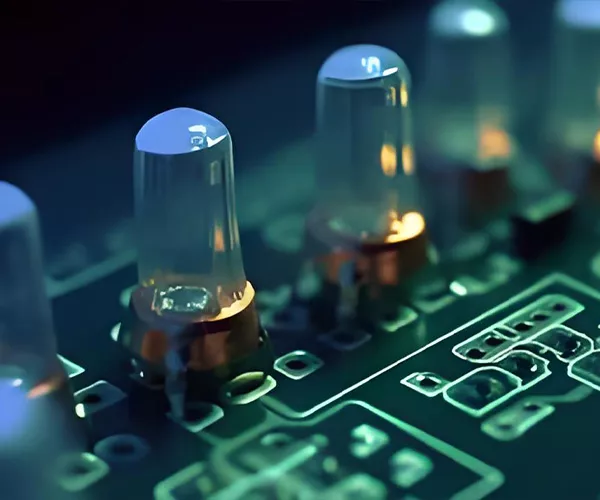

IGBT Modules: Si3N4 substrates can be used for heat dissipation in high-power devices such as new energy vehicles, electric vehicle drives, inverters, wind power generation, and rail transit.

MOSFET Modules: Silicon nitride substrates can improve heat dissipation efficiency and reliability in power management systems and high-frequency switching power supplies.

Semiconductors & LEDs

LED Heat Dissipation Substrates: Silicon nitride ceramic substrates can be used for high-power LED chip packaging, ensuring heat dissipation and extending lifespan.

RF Device (RF) Packaging: Substrates provide excellent thermal management and electrical insulation in 5G and satellite communications.

Aerospace & Defense

Radar and High-Power Microwave Devices: Silicon nitride substrates' high-temperature and thermal shock resistance make them ideal for radar and high-power microwave device applications.

Zastosowania przemysłowe

High-frequency welding module: Substrates used in high-frequency welding modules can improve heat dissipation and stability.

Industrial power supplies: Si3N4 substrates can be used for heat dissipation and electrical isolation in high-power converters.

Czy martwisz się minimalnym zamówieniem?

We offer a special minimum order quantity (MOQ) of one piece for Si3N4 ceramic substrates to meet the needs of individual merchants for small orders. Experience our service now.

Dlaczego warto wybrać GORGEOUS?

GORGEOUS places high priority on quality control, ensuring that every silicon nitride substrate meets customer specifications. Our rigorous quality inspection process ensures that every step, from raw material (silicon nitride powder) to finished ceramic (silicon nitride substrate), is precisely inspected and tested.

Furthermore, our factory is certified for automotive industry quality management systems according to IATF16949:2016 and ISO9001:2015, enabling us to provide our customers with the highest quality customized services.

Nasze sukcesy w przepustkach Referencje

The custom silicon nitride ceramic substrates we ordered from GORGEOUS exceeded our expectations. Their excellent performance is a perfect match for our module application.

James Anderson

The cooperation with GORGEOUS was very smooth. Through their detailed and professional technical support, the substrate was customized according to our design requirements.

Dawid

GORGEOUS is a trusted long-term supplier of silicon nitride ceramic substrates with good performance and high durability.

Jan

Często zadawane pytania

What is the thermal conductivity of aluminum nitride substrates?

The thermal conductivity of aluminum nitride substrates is typically between 170–200 W/m·K, several times higher than that of aluminum oxide, making it ideal for heat dissipation in high-power devices.

What are the electrical insulation properties of aluminum nitride substrates?

Aluminum nitride substrates offer excellent electrical insulation, ensuring stable operation of electronic devices in high-temperature, high-power environments.

What are the main applications of aluminum nitride substrates?

Aluminum nitride substrates are commonly used in power modules, LEDs, laser diodes, RF devices, and other electronic products that require high heat dissipation and reliability.

How does the cost of aluminum nitride substrates compare to aluminum oxide?

Although aluminum nitride substrates are relatively expensive compared to aluminum oxide, they offer a more cost-effective solution for high-end electronics and high-power applications