Introduzione

Hexagonal boron nitride is gaining significant popularity for its ability to efficiently manage heat in modern power electronics. Let’s explore their properties, benefits, how they improve thermal performance, and discover emerging trends, especially if you’re seeking better thermal management solutions.

What is Hexagonal Boron Nitride?

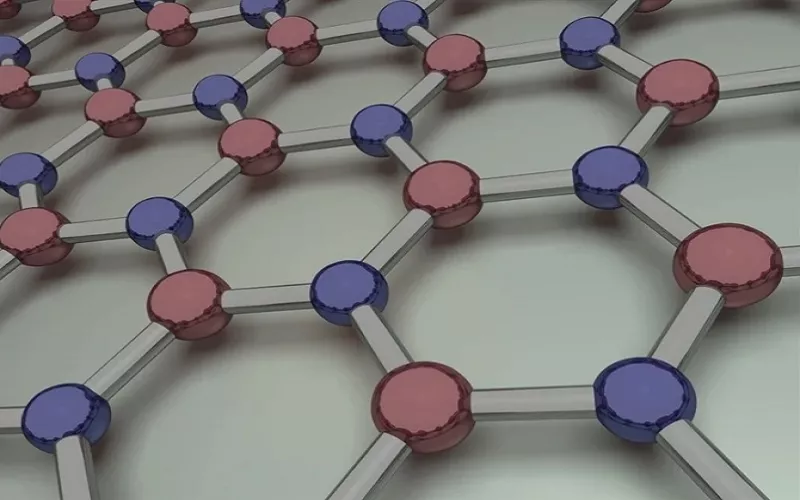

Diagram 1: Hexagonal Boron Nitride

nitruro di boro esagonale (h-BN) is a special material made from boron and nitrogen. It’s a ceramic material with atoms arranged in layered hexagonal sheets. You can also refer to it as the hexagonal form of boron nitride. Commonly called “Graphite”, the most stable and soft polymorph of boron nitride.

It’s a very useful material, especially in high-power electronic devices, because it conducts heat efficiently while remaining electrically insulating. Unlike many other thermal materials, h-BN tends to give your device the stable performance it requires at high temperatures.

Hexagonal boron nitride helps you remove heat from power components without allowing electrical current to pass through them. This is a highly sought-after feature that prevents electrical shorts, overheating, and damage to any equipment.

In most cases, you’ll find hexagonal boron nitride used as coatings, powders, sheets, or composite fillers. They make it possible to apply either an insulating layer, thermal interface material, or a heat-spreading component.

Today, manufacturers use it as an additive in cosmetics production or lubricants in industrial settings. h-BN is also used in inverters, power modules, substrates, EV, high-power electronics, and heat sinks that demand precise heat control. It works effectively in these equipments because:

-

It improves efficiency

-

Lowers operating temperatures

-

Support compact High-power features and designs

-

Increases the lifespan of your devices

-

It is chemically stable

-

Has low moisture absorption.

These features make it a very reliable option for thermal management in virtually any setting. Let’s see some of the key properties you’ll get to enjoy with hexagonal boron nitride:

-

Thermal expansion coefficient: 1 - 2 ×10⁻⁶ /K

-

Electrical resistivity: >10¹⁴ Ω·cm

-

Thermal conductivity (in-plane): 250 - 400 W/m·K

-

Thermal conductivity (through-plane): 2 - 30 W/m·K

-

Moisture absorption: <0.1%

-

Dielectric strength: 3 - 7 kV/mm

-

Density: 2.1 - 2.3 g/cm³

-

Chemical stability: Inert to most acids and alkalis

-

Maximum operating temperature (air): 900 °C

-

Maximum operating temperature (inert atmosphere): 1800 °C.

These properties also translate to your electronic devices made of hexagonal boron nitride.

Grades Types of Hexagonal Boron Nitride in Power Electronics

Today, the grade type of hexagonal boron nitride you choose matters just as much as the material itself. Your choice depends on the type of design you need, the heat load, or insulation needs. There are many options to pick from, and each one fits a different thermal management. Some are:

Boron Nitride Powder (h-BN Powder)

If you need flexible and scalable thermal solutions, then consider this very common form of hexagonal boron nitride. Most industries use it as fillers for polymers, greases, thermal interface materials, and adhesives. It mainly helps you improve heat dissipation in your device while maintaining electrical insulation.

Diagram 2: Composite fillers

You will find them available in different particle sizes and purities, which affect their prices and thermal performances.

Boron Nitride Coatings

Diagram 3: Boron Nitride Coatings

This is the type applied as thin layers on substrates or heat sinks. They prevent electrical shorting and improve heat circulation in your electronic devices.

These are considered a good choice if you have limited space and still want to prioritize thermal control. Engineers prefer to use them in compact electronic designs and other high-power electronic devices.

Boron Nitride Sheets and Plates

These are the types used as solid insulators or efficient heat spreaders, because they have been proven to offer stable performance at high temperatures.

They are also a good match for direct contact with electronic components. Interestingly, they are the easiest to use if you’re looking at customizing the layout design for your power electronics device. For example, momentive boron nitride, which is a ready - made product from top suppliers.

All these options come with consistent quality, save development time, and guarantee maximum performance. Also, they’re ideal for industrial, commercial, and household applications.

Benefits of Hexagonal Boron Nitride

There are many benefits from using hexagonal boron nitride, especially in power electronics. Some of them are:

-

You’ll get consistent electrical insulation while managing heat. Actually, unlike many thermal materials, h-BN allows the heat movement without risking any electrical short circuits.

-

Faster heat removal - Hexagonal boron nitride helps you remove heat faster from critical components in your electronic device. It does this by spreading heat efficiently, consequently reducing hotspots that normally damage devices.

-

Your electronic devices would be more reliable and durable. Why - Hexagon boron nitride allows them to work at lower operating temperatures. This means little or no premature failures and less thermal stress.

-

You get stable performance at high temperatures because h-BN doesn’t break down easily, even in high-stress environments.

-

If you’re using hexagonal boron nitride, then higher power densities wouldn’t be a problem. This is because h-BN allows you to pack more power into smaller designs without necessarily causing overheating issues.

-

Your equipment and devices will not run the risk of overheating. h-BN helps most power electronics devices to run smoothly and more coolly.

-

You will get to enjoy design flexibility due to the many forms of h-BN (boron nitride powder, solid forms, or coatings). This also means you can apply h-BN exactly where it fits your design.

-

There’s less maintenance for you to do with hexagonal boron nitride-based power electronics. This is largely due to better thermal control.

Future Trends in Hexagonal Boron Nitride

Diagram 4: Hexagonal Boron Nitride Future Trend

Hexagonal boron nitride is obviously making waves in today’s world. Now let’s review some of the future/emerging trends and see where h-BN is heading.

-

Rising demand in wide band-gap and high-power electronics

This will mean more uses for h-BN due to better thermal insulation. Obviously, Gallium Nitride and Silicon Carbide devices may likely not be able to handle rising demands in the near future.

-

Emerging electric vehicles and charging systems

Hexagonal boron nitride is one of the best options for power modules in EVs. They ensure better heat control, which these EVs and charging systems need.

-

More efficient, slimmer coatings

You’ll notice more improved and efficient coating techniques made from h-BN layers. More uniform, thinner, and more effective for compact designs.

-

Phasing into next-generation substrates

New generation chips and power modules now use more hexagonal boron nitride. This is because h-BN tends to manage heat better when technicians use it in electronic packaging.

-

Global rise in the use of engineered commercial solutions like momentive boron nitride.

Yes, it’s safe to say manufacturers craving consistent performance are moving towards ready-made h-BN products like Momentive Boron Nitride or Boron Nitride Powders.

You’ll notice one thing - These emerging trends keep increasing. Why - h-BN literally solves real thermal problems modern electronics can’t seem to ignore. Also, a significant feature to remember when it comes to hexagonal boron nitride is that it transfers heat efficiently even during electrical insulation. This is a very rare and valuable combination in power electronic devices.

Domande frequenti

Can the lifespan of power electronic devices be increased by hexagonal boron nitride?

Technically, it can. How - Hexagonal boron nitride will help your device clear hotspots that can disrupt key components and damage its overall performance/lifespan.

Is hexagonal boron nitride a safe and stable material for long-term electronic use?

Yes, it is, because it’s chemically inert and will comfortably resist oxidation for a long period.

Why is hexagonal boron nitride considered a better option compared to traditional thermal materials?

It’s because it can offer you better thermal stability at high temperatures. It also won’t conduct electricity or break down like other regular thermal materials.

A GORGEOUS CERAMIC(GGSCeramic), you can purchase any of these h-BN grade types to solve your thermal management needs. We offer one of the best services. Don’t sleep on this opportunity!

Conclusione

Hexagonal boron nitride consistently offers you outstanding thermal performance due to its amazing properties. The various forms, aside managing heat efficiently in your electronic devices also improves performance and lifespan. In need of better thermal solutions? Then try boron nitride-based options. They’re one of the best!