GORGEOUS CERAMICS (GGS) specializes in the research, development, production, and customization of alumina and zirconia ceramic heating elements. Leveraging our mature ceramic manufacturing processes and technical expertise, we provide customers with high-performance, stable, and reliable product solutions.

In the automotive sector, we custom-manufacture oxygen sensors for renowned brands such as Denso, Delphi, NTK, and NGK. The core function of an oxygen sensor is to monitor the oxygen content in vehicle exhaust in real time, enabling the engine control system to optimize fuel injection and combustion efficiency. Ceramic heating elements play a key role in this process—they rapidly heat the sensor during cold starts, allowing it to quickly enter operational status, improving monitoring accuracy and effectively reducing emissions.

With 15 years of expertise in tecnología de calentamiento cerámico, GORGEOUS CERAMICS (GGS) not only meets standardized requirements but also provides customized ceramic heating solutions, helping the automotive industry achieve more efficient and environmentally friendly emissions control.

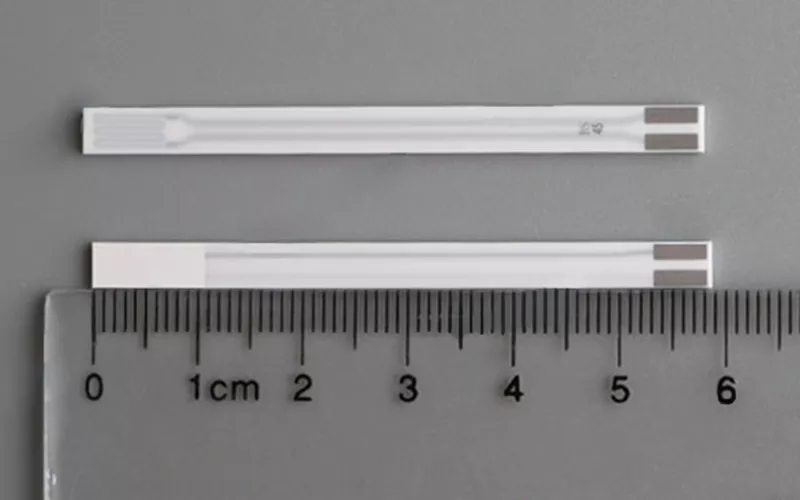

Basic Characteristics of Chip-Type Zirconia Heating Chip

GORGEOUS CERAMICS (GGS) new laminated planar oxygen sensor utilizes a composite design of alumina and zirconia, with the heating element embedded directly within the zirconia substrate. Using alumina as the heating substrate ensures efficient and uniform heating while also effectively compensating for the low thermal conductivity of zirconia.

Our new laminated planar oxygen sensor activates within 10 seconds after a cold start, significantly improving the response speed and accuracy of engine emissions monitoring, providing reliable support for automotive energy conservation and emission reduction.

Our sensors are specifically designed to measure the oxygen content in gasoline engine exhaust. The broadband lambda sensor, LSU 4.2, utilizes a planar ZrO₂ structure and an integrated, high-efficiency heater. It is a dual-cell, limiting current sensor.

The output signal remains monotonic within the air equivalence ratio (λ) range of 0.65, making the LSU precise for measurements at λ=1 while also providing flexibility across other λ ranges, making it a versatile sensor with broad applicability.

- Operating voltage: 13V ±1V

- Heating resistance: 9.5 ±1Ω

- Heater dimensions: 58.6*4.4*1.25mm

- Heater current: 0.5 ±0.1A

- Activation time: ≤5s

- Heating time to 350°C: ≤7s

- Peak temperature: 770°C ±50°C

- Operating temperature: 350-850°C