Wał ceramiczny

Custom Ceramic Shaft Supplier,Ceramic shafts Manufacturer ;Factory direct supply;Extended use by more than 10%!

Orders now! 10% Discount!

Custom Ceramic Shaft Supplier

Piękna zaleta

Ceramic Shaft Description

GORGEOUS has extensive experience in manufacturing ceramic shafts made of materials such as glinka, tlenek cyrkonu, I azotek krzemu.

Ceramic shafts are essential components for various pump applications, and their application range is wide, including various water pumps and motor equipment.

Ceramic materials have excellent wear resistance and can withstand long-term friction and impact. Compared with traditional metal shafts, ceramic shafts are more durable and are an economical choice for you to save costs!

Gwarancja czasu produkcji i wysyłki

Over 15 years of experience in advanced ceramic production to provide you with high-quality customized production services!

Your goods go through four processes: manufacturing, packaging, loading, and transportation. We serve you carefully and transparently in each process.

Produkcja i transport ceramiki zależą od procesu i Twojej lokalizacji. Szybko wyprodukujemy je dla Ciebie zgodnie z Twoim planem i wybierzemy najlepszą metodę transportu. Najszybsza dostawa lotnicza w Ameryce Północnej, dociera w ciągu 7 dni.

GORGEOUS współpracuje z wieloma wiodącymi firmami logistycznymi, w tym:

- MSC (Śródziemnomorska Kompania Żeglugowa)

- Maersk

- CMA-CGM

- COSCO

- Hapag-Lloyd

- DHL

- UPS

- FedEx

- TNT

Współpracujemy z wieloma spedytorami, aby zagwarantować Ci wydajne opcje wysyłki po niższych cenach, dostawa na czas, I bez ukrytych opłat!

Produkcja

Uszczelka

Załadunek

Transport

Main Properties of Ceramic Shafts

Wysoka twardość

Ceramic materials are harder than traditional metals

Odporny na zużycie

It can withstand greater friction without being easily worn and has a long service life.

Odporny na korozję

Not easily corroded by chemicals, and resistant to most acids, alkalis, salts, etc.

Odporność na wysoką temperaturę

It can resist extreme high temperature and is not prone to deformation.

Izolacja elektryczna

Excellent electrical insulation, can be used in electrical equipment.

PIĘKNY Dostosowywalny produkt Dokładność odniesienia

| Shaft Part | Cylindricity can reach 0.003mm |

| Coaxiality can reach 0.002mm | |

| Chropowatość 0.02 | |

| Minimum Processing Hole Diameter | Up to 0.3mm, depth limit is 3mm |

| Hole depth accuracy can reach 0.005mm | |

| Chropowatość 0.02~0.04 | |

| Plane Machining Tolerance | Parallelism accuracy can reach 0.002 |

| The measurement tolerance is 0.0015mm | |

| Ceramic Thread Machining | Processing internal thread size limit M3.0 |

| Thread accuracy gb-7h | |

| No restrictions on external thread size | |

| Thread accuracy can reach gb-6g |

*Szczegółową dokładność należy określić na podstawie rzeczywistego materiału, kształtu i wymagań procesowych produktu.

Ceramic shaft standard size and specifications

Diameter Range

Micro shaft: 0.5mm - 3mm (commonly used in micro motors)

Conventional shaft: 3mm-20mm (pumps, valves, bearings, etc)

Large shaft: 20mm-50mm or larger (high temperature furnace drive shaft)

Length Range

Short axis: 5mm-50mm (micro motor or sensor)

Medium-long axis: 50mm-300mm (mechanical field)

Extra-long axis: 300mm-1000mm (special equipment)

Examples of Common Diameters

Small diameter: 1mm, 2mm, 3mm, 5mm, 6mm, 8mm

Medium diameter:10mm、12mm、15mm、20mm

Large diameter:25mm、30mm、40mm、50mm

「Support non-standard customization」

「MOQ 1 piece sample order」

Customized Ceramic Shaft Material Parameters and Selection

Guide to Choosing Various Ceramic Materials!

✔️Glinka: Alumina shaft is the cheapest among many materials, with a very high cost performance. Its density is 3.7-3.92g/cm3 . You can choose 95%, 99%, 99.5%, 99.7% and other purity alumina for customization.

✔️Cyrkonia: The density of zirconia shaft is relatively large, exceeding 6.0g/cm3. It has stronger fracture performance than other materials, overcomes the brittleness of ceramics, and it is also self-lubricating, which is very suitable for shaft and pump applications. In addition, you can also choose TTZ, YTZP, ZDY, ZTA and other materials.

✔️Silicon nitride: Silicon nitride shafts are more expensive, but they are lighter and can be polished to a mirror finish of Ra0.05um.

✔️Silicon carbide: The density of silicon carbide shafts is similar to that of silicon nitride, and their hardness is higher than that of general ceramic materials, and their wear resistance is also better.

| Przedmiot | Jednostka | Ceramika cyrkonowa |

| Gęstość | g/cm3 | 6.0 |

| Zawartość cyrkonii | % | 94.4 |

| Wielkość ziarna | mikrometr | 0.5 |

| Twardość Rockwella (45N) | R45N | 78 |

| Twardość Vickersa (obciążenie 500 g) | GPa(Kg/mm2 ) | 11,5 (1175) |

| Wytrzymałość na zginanie (20℃) | MPa | 800 |

| Wytrzymałość na ściskanie (20℃) | MPa | 2000 |

| Wytrzymałość na pękanie (20℃) | MPam1/2 | 9.0 |

| Przewodność cieplna (20℃-400℃) | W /(mk) | 2.5 |

| Współczynnik rozszerzalności cieplnej | 10-6 /℃ | 9.6 |

| Odporność na szok termiczny | △T℃ | 250 |

| Nieruchomość | Jednostka | glin2O3 99.7 | glin2O3 99.5 | glin2O3 99 | glin2O3 95 |

| Czystość | — | 99.7% | 99.5% | 99% | 95% |

| Gęstość | g/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| Wytrzymałość na zginanie | MPa | 375 | 370 | 340 | 304 |

| Wytrzymałość na ściskanie | MPa | 2450 | 2300 | 2250 | 1910 |

| Moduł sprężystości | GPa | 380 | 370 | 330 | 330 |

| Wytrzymałość na pękanie | MPam1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| Twardość | HRA | 91 | 91 | 90 | 89 |

| Twardość Vickersa | HV1 | 1600 | 1550 | 1450 | 1400 |

| Współczynnik rozszerzalności cieplnej | 10- 6 K-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| Przewodność cieplna | W/mk | 32 | 32 | 25 | 25 |

| Stabilność szoku termicznego | △T.℃ | 220 | 220 | 200 | 200 |

| Maksymalna temperatura pracy | ℃ | 1750 | 1750 | 1700 | 1500 |

| Rezystancja objętościowa przy 20℃ | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| Wytrzymałość dielektryczna | KV/mm | 22 | 20 | 16 | 15 |

| Stała dielektryczna (temperatura pokojowa) | / | 10 | 11 | 11.5 | 11 |

| Współczynnik strat dielektrycznych MHz | opalony δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

Dostosowywalny ceramiczny koniec wału Typ odniesienia

🔷Straight: can be directly mounted to bearings, bearing seats, brackets, etc.

🔷Keyed: can be precisely combined with your machine to transmit torque to gears, sprockets, etc.

🔷D-Profile: one end is flat and allows insertion into the shaft to firmly install gears, sprockets and bearings, etc.

🔷Splined: can be customized with multiple keyway-like grooves, which can be used in hydraulic systems and machine tools.

🔷With Retaining Ring Grooves: can clamp the retaining ring into the groove, which can be used to separate and locate bearings, rings and sprockets.

🔷Step Down: can use the shoulder near the end of the shaft as a shaft support.

🔷Threaded: the end of the shaft is threaded and can be linked to threaded accessories.

🔷Tapped: has threads inside and can be installed on threaded posts.

🔷Hollow: lighter than solid shafts, can reduce the overall weight of the equipment, can be used for wires, compressed air pipes, etc.

Application of Ceramic Shaft

Ceramic Motor Shaft

Ceramic motor shafts are used in various motor equipment and have a longer life than traditional metal shafts.

Ceramic Shaft for Impeller

Ceramic shaft for impeller, extremely corrosion resistant

Ceramic Shaft for Water Pump

Ceramic shafts for water pumps, used in various water pump equipment, with excellent durability

Engine Ceramic Shaft

Used for various automobile engine shafts, bicycle axles, etc., with strong high temperature resistance.

Mechanical Equipment Shaft

Ceramic shafts for various mechanical equipment.

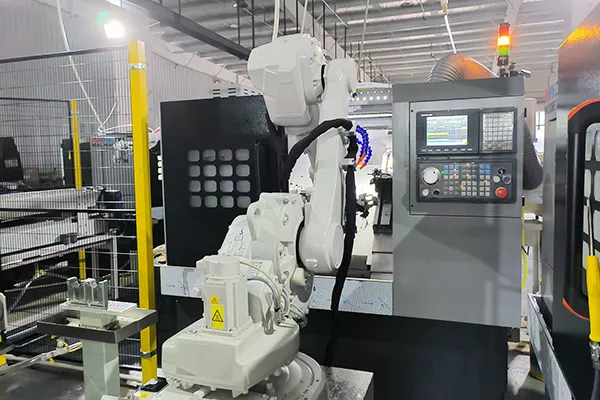

One-stop ceramic shaft manufacturing service

15+ Lata doświadczenia. Wysoka precyzja i projekt OEM. Profesjonalny zespół badawczo-rozwojowy. Konkurencyjna cena.

Ceramic Shaft vs. Metal Shaft

Ceramic shafts have excellent wear resistance and corrosion resistance, especially in some high temperature and corrosive environments.

Metal shafts have better impact and vibration resistance, but are easily corroded and worn.

Ceramic Shaft Manufacturing Process

- Raw material preparation: Select and process suitable ceramic raw materials.

- Molding: Dry pressing, injection molding, etc.

- Drying: Remove moisture after molding and wait for sintering.

- Sintering: High temperature sintering to form a hard ceramic structure.

- Post-processing: Precision machining or other processing.

How to Customize Poducts?

You only need to send us an inquiry and drawings, and our professional team will customize it for you.