Boron Nitride cbn is an advanced ceramic known for its superior properties. BN chemistry has 붕소 질소 bonds that give rise to different structures. Of the structures of BN one such prominent structure of interest is Cubic Boron Nitride cbn. Let us try to understand c-bn and its relative aspects.

Table of Contents

- What is cubic Boron Nitride?

- Structure of Cubic Boron Nitride

- 입방정 질화붕소 특성

- 입방정 질화붕소 대 다이아몬드

- 입방정 질화붕소 사용

- Super abrasive wheels – or diamond c-BN wheel

질화붕소: An Overview

질화붕소 is indicated by chemical formula “BN.” As earlier mentioned, 질화붕소 exist in different forms. Generally, it is the location of Boron and Nitrogen in lattice that creates various Boron Nitride structures. Some of them are quiet famous such as amorphous, hexagonal, cubic and Wurtzite.

When it comes to functionality, Boron Nitride ceramic is highly machinable. Once machined they does not really require any heat sintering or treatment for stabilization. In addition, 질화붕소 has higher heat capacity and is also a good electrical insulator.

For now, let’s try to understand derivatives of BN, 육방정계 질화붕소(h-BN) and another Cubic Boron Nitride (c-BN)

육방정계 질화붕소(h-BN)

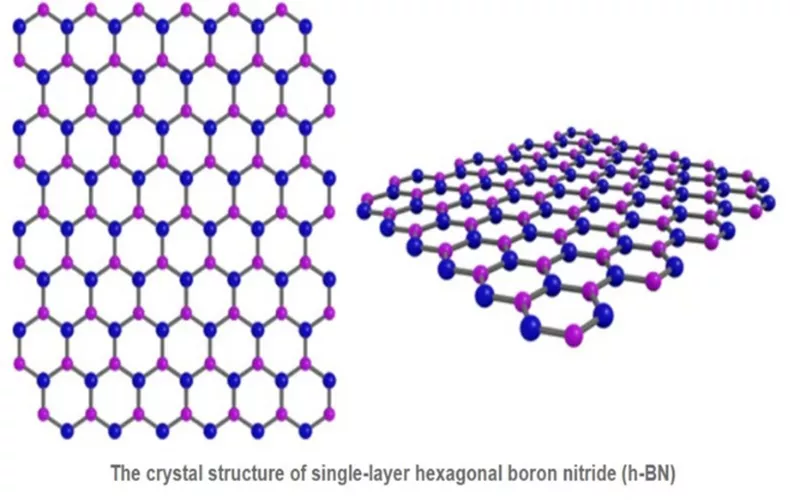

Structure of Hexagonal Boron Nitride

육각형 질화붕소 is a constituent in many industrial products such as cosmetics. HBN has a structure controlled by covalent bonds. However, the layers in HBN obey wander Waals forces. The plate like geometry of HBN is the reason why it is ideal for lubrication.

육각형 질화붕소 has elements of Boron and Nitrogen fixed to its lattice. The arrangement has three nitrogen atoms attached to a Boron Atom. The similarity in the honeycomb structure is the reason for its analogy with carbon. In addition to, properties of mechanical, chemical strength and electrical insulation are due to the planar triangular bonds

Properties of Hexagonal Boron Nitride

육각형 질화붕소 is popularly manufactured through Boric Oxide nitridation at elevated temperatures. Since its stability is closer to graphene, 육각형 질화붕소 is often acclaimed as the most advanced technical ceramic. Some superior properties of 육각형 질화붕소 열전도도와 마찰계수가 낮습니다.

육방정계 질화붕소의 응용

- HBN is used on nanoelectronics devices as a substitute to graphene substrate

- 육각형 질화붕소 in its thin form is used as coatings that resists corrosion

- HBN is often used in the manufacture of sensor materials. It is also used in electron tunneling due to its low value of dielectric constant.

입방정계 질화붕소

What is cubic Boron Nitride?

c-BN은 다음의 파생물입니다. 육방정계 질화붕소(h-BN) produced under high temperature and pressure.

가장 큰 특산품은 c-BN 세계에서 두 번째로 단단한 재료의 자리를 차지하고 있다는 것입니다. 기계적 강도는 입방정 질화붕소 다이아몬드와 동등할 정도로 인기가 높습니다. 붕소의 가장 인기 있는 다형체 중 하나입니다. 질화물.

Structure of 입방정계 질화붕소

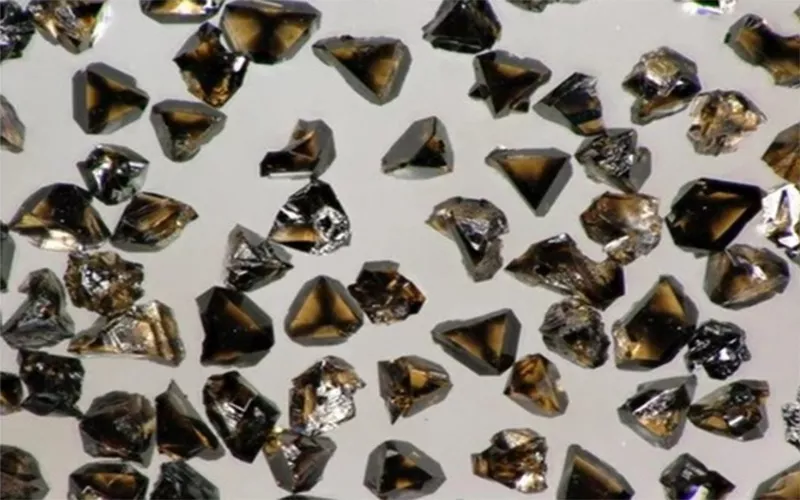

The basic structure of 입방정계 질화붕소 is crystalline. It has density around 3.5 g/cm3 and appears in pale yellow or transparent complexion. C-BN follows alternate arrangement of Boron and Nitrogen atoms. Here, the 붕소 질소 atoms follow covalent bonding which is the basic reason of its hardness and stability.

Cubic Boron Nitride Formula is given as c-BN. There are two popular types of c-Bn available today in the market. One is dense 입방정 질화붕소 and the other polycrystalline cubic Boron Nitride.

Cubic Boron Nitride Properties

C-BN is a brilliant semiconductor whose bandgaps are susceptible to changes in applied pressure. These changes in bandgap helps them excel as electric insulators. 입방정계 질화붕소 are generally inert and possesses low dielectric constant value. Their thermal conductivity is around 1300 KW/MK.

When it comes to reactivity, c-BN remains non-respondent even to ferrous materials. The optical range dealt by 입방정 질화붕소 varies from Ultra violet to the visible spectrum.

입방정 질화붕소 대 다이아몬드

다이아몬드보다 단단하지는 않지만, 입방정 질화붕소 다이아몬드와 비교했을 때 특별한 위치를 차지합니다. Cubic boron Nitride hardness is 4500 Kg/mm2 whereas diamond has hardness around 600 Kg/mm2.The value of modulus both young’s and bulk are also in similar range of 800 – 1000 and 370 – 450.

Furthermore, when it comes to structure, like diamond, c-BN has its two base atoms that are different. The similarity of both diamond and c-BN is generally attributed to the lookalike structure they possess.

입방정 질화붕소 사용

CBN 절삭 공구 소재

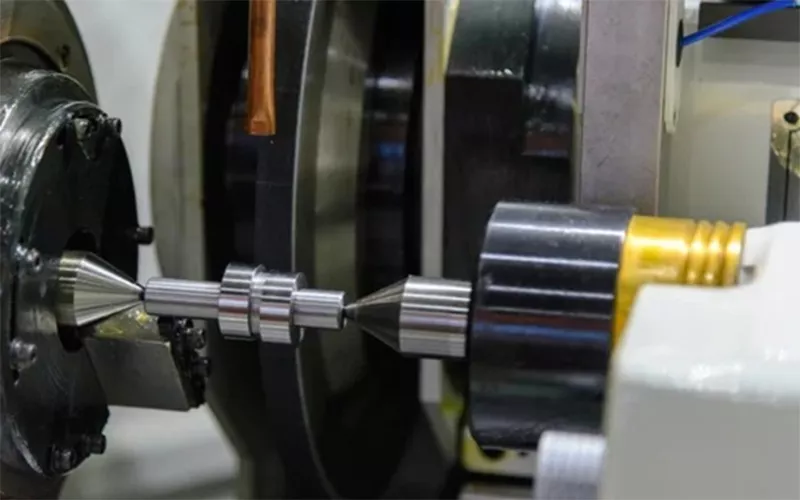

입방정계 질화붕소 exhibits both young’s and Bulk modulus greater than Boron Carbide and Silicon Carbide. This very reason strongly contributes to the hardness of cubic Boron Nitride. The hardness makes them suitable as abrasives and help them function as CBN 절삭 공구 소재. Generally Dense c-Bn is used for cutting application and porous type for grinding requirements.

The inert nature of Cubic Boron Nitride also helps them function as cutting and machining material. Unlike diamond it doesn’t react to iron. However, conventional c-Bn requires manipulation for utilising it in cutting application. This is generally done during the conversion of h-Bn to c-Bn while sintering.

cbn as electrical insulators

Apart from hardness 입방정계 질화붕소 also excels in electrical insulators. This is attributed to their wide bandgap.

cbn in semiconductor applications

By coating aluminium and Group 8 metals, C-BN functionality of becoming a sink is popular in electronic industry. C-BN is used as heat sink in lasers, microelectronic devices and LEDs.

입방정계 질화붕소 also adds value during semiconductor synthesis to obtain p and N type by proper doping. The common materials used for doping are Silicon or Beryllium. These semiconductors work at high temperature and are used in UV sensors.

c-BN 연삭 휠

의 발명 c-BN 연삭 휠 merited precision manufacturing due to the increased efficiency. wheels made up of c-BN contributed to industries such as aerospace, machines, tool production and automobile. c-BN 연삭 휠 also offer high hardness and good performance on comparison with SiC and Alumina. They ensure structural integrity at higher temperature and undergo no degradation.

The wheels of c-BN can withstand high temperature and deals with the amount of heat generated during the process. The resistance to wear and tear is also economically beneficial while considering c-BN grinding wheels. c-BN grinding wheels offer excellent surface finish and keeps away the work piece wastage. It also ensures lesser cycle time as the tasks are done quickly and precisely.

Super abrasive wheels – or diamond c-BN wheel

The super abrasive wheels are the ones differ from conventional wheel of Sic and Alumina. They are made from combining c-Bn and diamond. The super abrasive wheel offers better thermal conductivity limiting the rise in temperature of the workpiece. The 다이아몬드 c-Bn 휠 또한 더 긴 수명에 기여하는 높은 정확도와 정밀한 절단 기능을 제공합니다.

결론

입방정계 질화붕소 현대 과학 및 소재 제조 분야에서 선호되는 소재입니다. 다이아몬드와 같은 소재와 비교했을 때 경쟁력이 있으며, 경도, 강도, 전기 절연성 등의 특성이 뛰어납니다. 넓은 밴드갭, 불활성, 낮은 유전율, 그리고 광학적 특성 또한 장점으로 꼽힙니다.