GORGEOUS CERAMICS (GGS) is a manufacturer specializing in the production of alumina ceramic biomass boiler igniters.

Nostro igniters are manufactured using an advanced ceramic lamination process, resulting in excellent high-temperature resistance and durability, ensuring stable and reliable ignition.

Choose us! We have professional technical support to ensure the high quality of biomass boiler igniters, and we can also provide the best after-sales support and fast delivery.

Alumina Igniter Parameters

Manufactured using a ceramic lamination process, the MCH alumina biomass boiler igniter features a compact structure, high power output, rapid heating, and reliable and stable performance.

Widely applied in automotive, medical, and semiconductor fields, this ceramic heater provides an innovative and reliable heating solution.

|

Implementation |

Pellet Combustion Burner /biomass Fired Boiler |

|

Ceramic seat |

17.5mm/25mm or equivalent size |

|

Operating voltage |

120V+/-10% |

|

230V+/-10% |

|

|

Heating element |

95% Al₂O₃ White Ceramic |

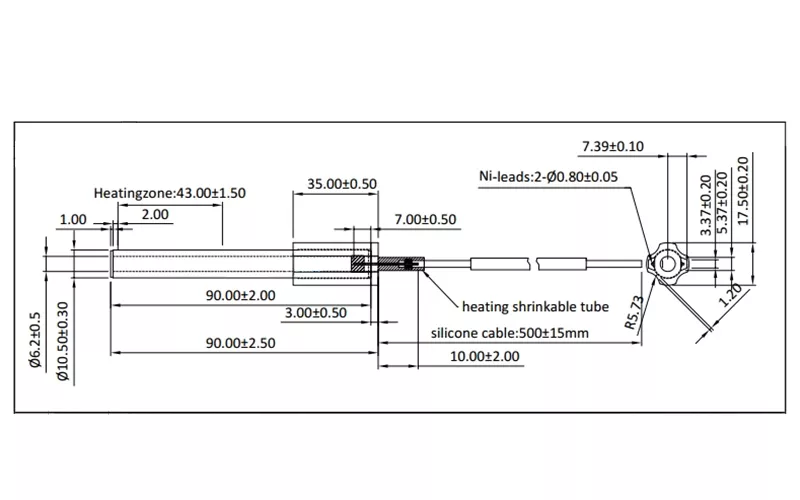

Primary Dimensions of Alumina Ceramic Igniter:

1. Heater: White alumina ceramic, alumina content greater than or equal to 95%.

2. Nickel wire: N6 nickel wire, 0.8mm in diameter.

4.3 Brazing filler : Ag72Cu28

3. Ceramic base: 95% alumina ceramic, 17.5mm diameter

4.Heat shrink sleeve: Black, capable of withstanding temperatures up to 180°C.

5. Cable: Silicone-insulated, rated for 180°C heat resistance.

General Characteristics of Alumina Igniters

|

Caratteristica |

Standard |

Condizione |

|

Forward current |

AC220V+/-10% |

50/60 Hz |

|

Power consumption |

220V |

114W~134W |

|

230V |

120W~150W |

|

|

240V |

131W~160W |

|

|

Resistenza |

Corresponding value |

23℃±2°C |

|

Heating time |

The temperature rises to 800°C in 30 seconds 940°C in 120 seconds |

Applicable to AC 220V, ambient temperature 23℃±2°C |

|

Maximum temperature |

1050°C |

|

|

Resistenza di isolamento |

Minimum 500VDC - 100MOmbra Temperature 23°C ± 2°C Humidity 65%±10% |

Tester: Insulation resistance tester. A 10% ammonium nitrate solution was placed in the heating area and a 500 V DC voltage was inserted at a distance of 5 cm from the electrode. |

|

Pressure resistance |

AC1500V, 1 second, leakage current less than 5mA |

Tester: Pressure tester. Place tap water in the heating area and plug in a 1500V AC power supply at a distance of 5 mm from the electrodes for 1 second. |

|

Nickel wire tensile test |

≥ 3.0Kgf |

Tester: Tensile Testing Machine . Degree: 45°C |

|

Startup test |

When the device runs at the set voltage for one minute, it can avoid problems such as no heating, uneven heating and explosion. |

Install the heating wire into the test device and operate it for one minute under the condition of inputting a stable voltage. |

|

Electrical Resistance test |

Thermal Resistance : corresponding |

Tester: DC Resistance Tester |

|

Aspetto |

Defects such as color mixing, cracks, pinholes, scratches, contamination, or chipping are not permitted. The leads must be soldered at right angles. |

You can use visual method. If the defects are difficult to identify,ou can be inspected using an X20, X100, or X200 microscope. |

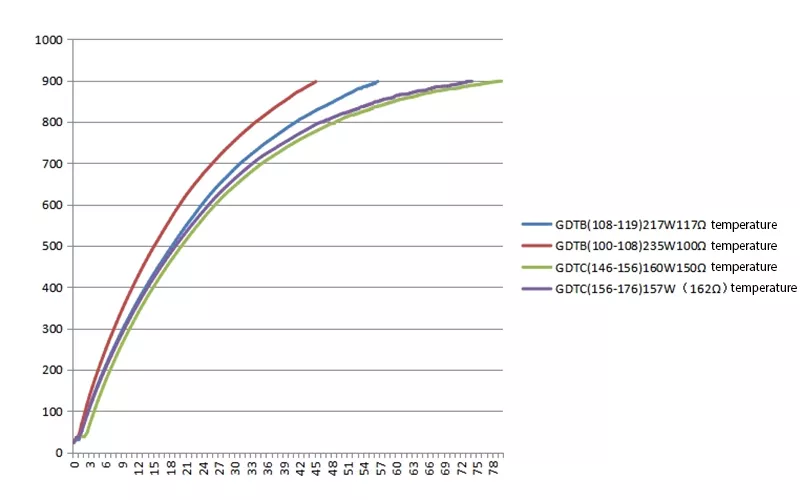

Ignition Heating Rate (Reference)

The igniter heats up slightly differently depending on the resistor.

The graph below shows the effect of different temperatures on different resistor values.

Biomass Boiler Ignitor Applications

- Wood Pellet Stoves

- Wood Pellet Boilers

- Wood Pellet Burners

- Wood Chip Burners

- Straw Burners

- Other Biomass Burners