Offriamo servizi completi di produzione personalizzata per realizzare componenti complessi e di alta precisione.

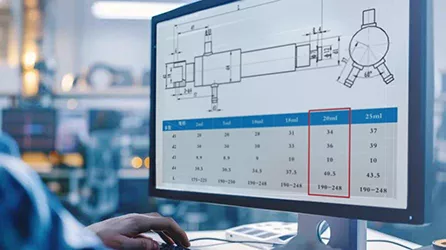

Esperienza nella progettazione e nello sviluppo di soluzioni ceramiche avanzate personalizzate per varie applicazioni.

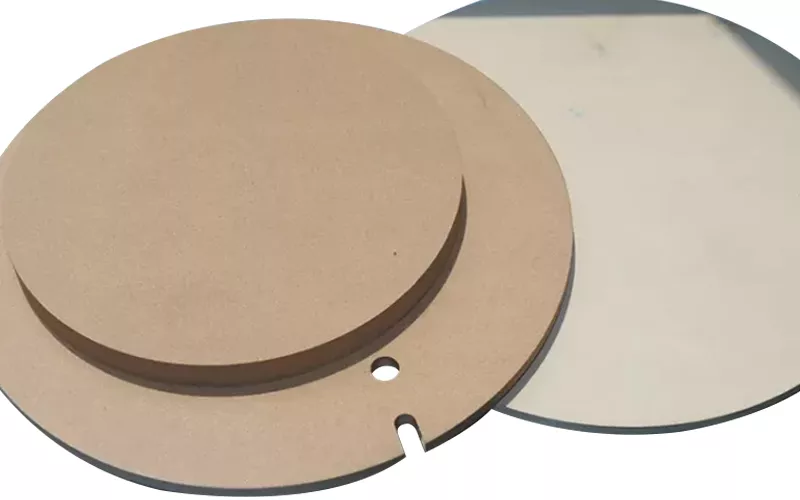

Abbiamo una vasta esperienza nella fresatura, rettifica e lucidatura di ceramiche tecniche ad alta precisione.

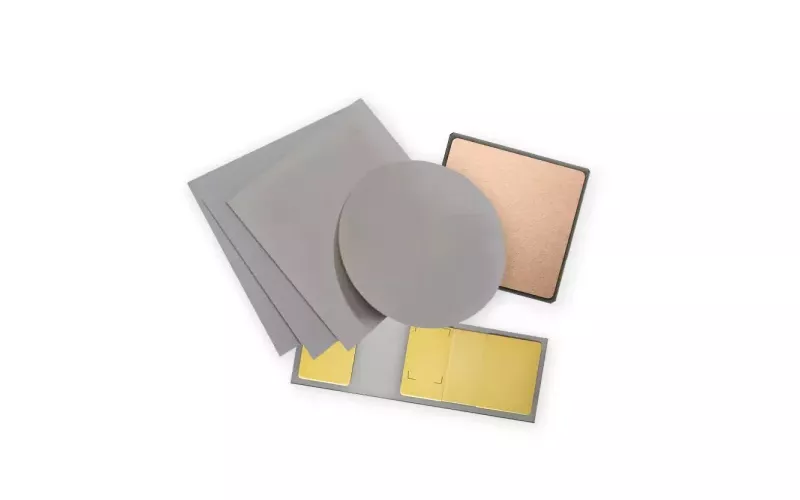

Materiali ceramici personalizzabili

Offriamo un'ampia selezione di materiali ceramici ad alte prestazioni, tra cui allumina, ossido di zirconio, nitruro di alluminio, nitruro di silicio, nitruro di boro, carburo di silicio, carburo di boro e ossido di berillio. GORGEOUS CERAMICS (GGS) vi assisterà nella scelta del materiale più adatto alle vostre esigenze applicative, raggiungendo il giusto equilibrio tra prestazioni e costi.

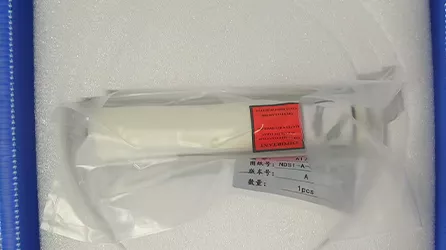

GORGEOUS Prodotti più venduti!

Rispondiamo alle esigenze avanzate in ambito ceramico di diversi settori. Che le vostre esigenze includano componenti ceramici standard resistenti alle alte temperature e alla corrosione, componenti ceramici ad alta precisione per l'industria dei semiconduttori o riscaldatori ceramici con risposta rapida ed elevata efficienza energetica, possiamo fornirvi soluzioni personalizzate collaudate e ad alte prestazioni, garantendo una transizione fluida dalla progettazione alla produzione di massa.

Di seguito sono riportati alcuni dei prodotti più venduti di GORGEOUS CERAMICS (GGS)!

Riscaldatore in ceramica

Accenditore in ceramica

Substrato ceramico

Ceramica semiconduttrice

Ceramica microporosa

Passaggio

GORGEOUS CERAMICS (GGS)

– Il tuo partner di fiducia

Prodotti venduti in tutto il mondo

Con sede in Cina, GORGEOUS CERAMICS (GGS) esporta i suoi prodotti ceramici avanzati in tutto il mondo, con l'obiettivo di fornire ai clienti soluzioni di produzione rapide, di alta qualità e su richiesta.

In qualità di fornitore leader di ceramiche avanzate in Cina, supportiamo le spedizioni globali, effettuando consegne nelle principali regioni del Nord America e dell'Europa in appena 3-10 giorni.

I nostri ingegneri di progetto parlano tutti inglese. Nei giorni feriali, rispondiamo rapidamente, interagendo perfettamente con le esigenze dei clienti, indipendentemente dal fuso orario, e garantendo un avanzamento fluido del progetto, dalla prototipazione alla consegna.

30,000㎡ 20,000+ 120+

Factory floor area Global customers The country of service

Dallo sviluppo di nuovi prodotti alle soluzioni

GORGEOUS CERAMICS (GGS) offre molto più di semplici servizi di produzione. Forniamo soluzioni di sviluppo prodotto a ciclo completo, dalla progettazione e prototipazione alla produzione e al confezionamento.

Ceramica avanzata personalizzata per diversi settori

I nostri prodotti ceramici trovano ampia applicazione nei settori aerospaziale, automobilistico, dei semiconduttori, dell'elettronica, dei macchinari, chimico e medico.

Aerospaziale

Automobilistico

Elettronica

Industria meccanica

Medico

Chimico

Le nostre applicazioni di fabbricazione della ceramica

GORGEOUS CERAMICS (GGS) fornisce servizi di produzione di ceramiche personalizzate per creare strutture, macchine e parti, tra cui:

Cosa dicono i nostri clienti

GORGEOUS ha comunicato molto bene con noi, ha sempre capito accuratamente le nostre esigenze e ha risposto tempestivamente.

Carlo

La loro velocità di produzione è incredibile, i nostri ordini vengono sempre consegnati in tempo, la qualità è eccellente ed è un piacere lavorare con loro.

LEI ZAN

Siamo davvero soddisfatti del loro servizio! Risolvono subito qualsiasi problema, dimostrando professionalità ed efficienza. Un grande grazie a GGS!

Hans

Risorse correlate

Applications of Silicon Carbide Bearings and Shafts in High-Speed and Wear-Intensive Industries

Standard material-made bearings often fail in harsh chemical, advanced engineering, and fast-moving industries. Rather, silicon carbide bearings perform exceptionally well in these fields.Let’s explor…

Silicon Carbide vs Steel FGD Nozzles: Which Reduces Downtime?

Steel desulfurization nozzles fail in 6-12 months due to wear and clogging. Silicon carbide nozzles last 3-5 years with excellent corrosion resistance. This guide covers performance comparison, total …

Silicon Carbide Bulletproof Plate: Lightweight, Reliable & Safe

Your silicon carbide bulletproof plate offers exceptional hardness, low density, and great shock resistance. In your defense equipment manufacturing, SiC translates to superior, lightweight bulletproo…

Invia un preventivo rapido

Perché GORGEOUS ha la fiducia di 1000+ clienti?

La nostra produzione di ceramica industriale offre numerosi vantaggi a diversi settori, aziende o progetti. Ecco i vantaggi dei nostri servizi.

Produzione conveniente e veloce

GORGEOUS è in grado di produrre rapidamente diversi prototipi in ceramica e prodotti finiti. GORGEOUS offre una produzione rapida garantendo al contempo un'elevata precisione. La nostra produzione su larga scala ci consente inoltre di fornire servizi di produzione ceramica a costi contenuti.

Ottimo rapporto resistenza/peso

Grazie alla nostra avanzata tecnologia di fabbricazione, possiamo produrre componenti in ceramica di alta qualità e al tempo stesso resistenti. Garantiamo elevata resistenza, resistenza ai graffi e alla corrosione a tutti i prodotti ceramici realizzati.

Ampia gamma di materiali e tecniche utilizzate

Siamo esperti in diverse tecniche di fabbricazione di materiali ceramici che ci consentono di produrre parti complesse con caratteristiche aggiuntive intricate come tacche, fessure, fori, ecc. La nostra ampia gamma di materiali ceramici può anche resistere a resistenza termica, resistenza alla corrosione e altro ancora.