Substrat d'alumine

GORGEOUS is a leading international ceramic supplier, specializing in providing customers with alumina substrate products used in the electronics and semiconductor manufacturing fields. Various purities and sizes can be customized.

Manufacturing High-Quality Alumina Substrates

GORGEOUS can supply customers with alumina substrates with a purity of 99.6%.

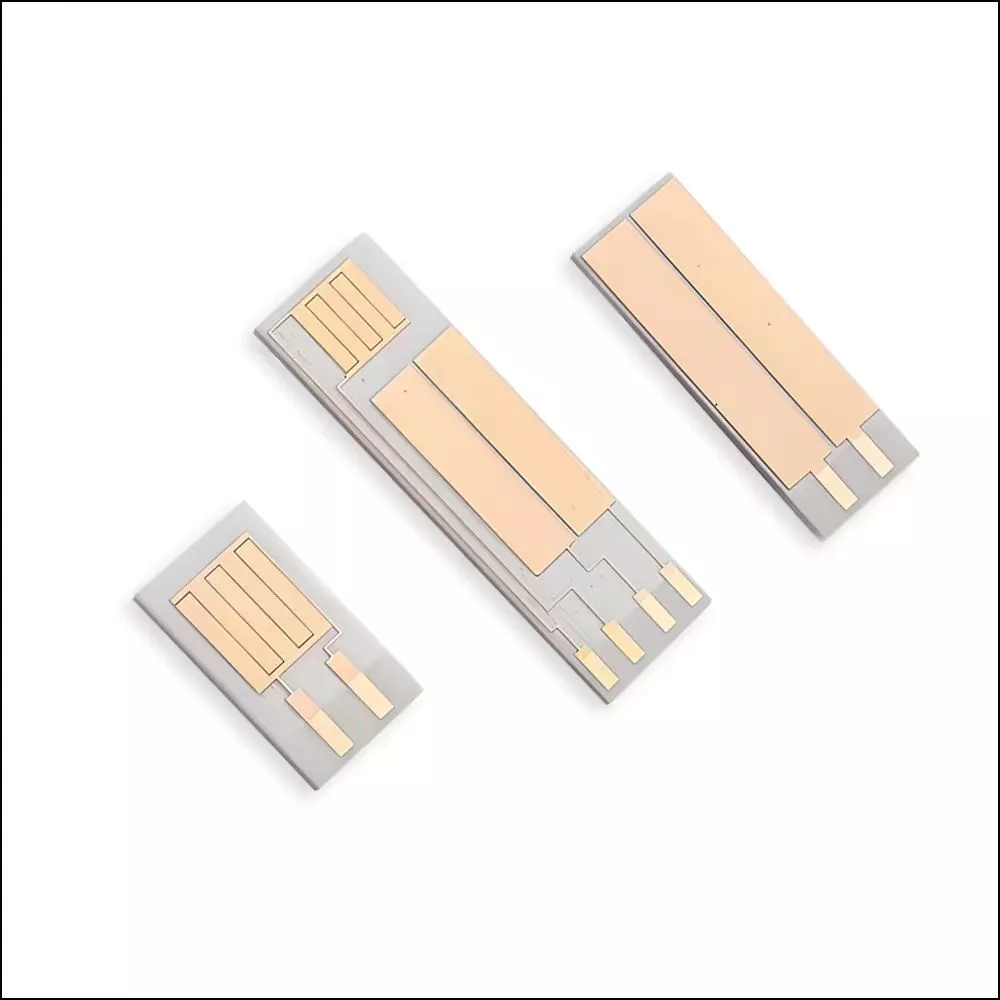

We also offer thin-film and thick-film metallized ceramic substrates.

Product Advantages:

- High smoothness and extremely low porosity

- Minimal warping, bending, and undulation

- Excellent physical and chemical stability in high-temperature environments

- Excellent insulation, high dielectric breakdown voltage, and high surface and volume resistivity

- Excellent mechanical strength

- Oil and chemical resistance

Leading Global Manufacturer of Alumina Substrates

GORGEOUS has over 15 years of expertise in high-performance ceramic substrate manufacturing, specializing in alumina substrates, PCBs, and thin-film ceramic substrates. Our products are widely used in electronics, power modules, LED packaging, and advanced semiconductor applications.

Our advanced production lines and testing equipment ensure that every substrate we produce meets the highest standards of precision, reliability, and thermal performance. From raw material processing to final inspection, every step is subject to rigorous quality control.

Our experienced team of engineers provides customized design support and technical guidance, helping customers optimize their solutions for improved performance and cost-effectiveness.

With GORGEOUS, you gain not only a supplier but also a trusted manufacturing partner capable of large-scale production and rapid delivery.

Alumina Ceramic Substrate/Alumina Substrate PCB Products

We offer flexible alumina substrates and customized alumina PCB services to meet diverse customer needs.

We provide advanced processing solutions, including:

- Thin-film ceramic substrate manufacturing – precision surface treatment and thin-film circuit integration

- Metallization – such as Mo/Mn+Ni plating, tungsten-based metallization, and thick film printing

- Laser cutting and drilling – suitable for complex shapes, through-holes, and high-precision microstructures

- Polishing and surface treatment – ultra-smooth surfaces for superior thermal and electrical performance

- Substrate assembly support – enabling direct placement of electronic components

Taille standard du substrat

| Taille du substrat (mm) | Erreur dimensionnelle (mm) |

| 50.8*50.8 | ±0,2 |

| 76.2*76.2 | ±0,3 |

| 101.6*101.6 | ±0,4 |

Épaisseur du substrat

L'épaisseur du substrat est de 0,1 à 3 mm, avec des épaisseurs typiques de 0,254, 0,381, 0,508 et 0,635. La tolérance d'épaisseur du substrat est de ±10%.

| épaisseur (mm) | Tolérance d'épaisseur (mm) | ||

| Tiré | Sol | Brillant | |

| 0.127 | ±0,012 | ±0,005 | ±0,005 |

| 0.254 | ±0,025 | ±0,005 | ±0,005 |

| 0.381 | ±0,038 | ±0,005 | ±0,005 |

| 0.508 | ±0,050 | ±0,01 | ±0,01 |

| 0.635 | ±0,063 | ±0,01 | ±0,01 |

| 0.762 | ±0,076 | ±0,01 | ±0,01 |

| 1.016 | ±0,10 | ±0,01 | ±0,01 |

Capacités techniques

| Type de substrat | Rugosité de surface | Déformation |

| Tiré |

Avant : ≤ 100 nm Arrière : ≤ 200 nm |

0.3% |

| Sol | Selon les exigences du client | 0.1% |

| Brillant | ≤ 25 nm | 0.1% |

Alumina Substrate Applications

Electronics and Semiconductor Fields

Alumina substrates offer excellent electrical insulation and heat dissipation properties, and can be used in printed circuit boards (PCBs) and hybrid integrated circuits (HICs).

Common applications for these substrates in the electronics and semiconductor fields include semiconductor packaging substrates, thick/thin film circuit substrates, and sensor carriers.

Communications and RF Fields

Alumina substrates can be used in the communications and RF fields as RF circuit substrates and microwave device substrates. They maintain low dielectric loss and stable signals in high-frequency communications (such as 5G base stations and radar systems). As microwave device substrates, they are often used in devices such as filters, power amplifiers, and couplers to ensure high-frequency characteristics.

Automobile and New Energy

Alumina substrates can be used in automobiles and new energy vehicles as heat dissipation for power modules such as IGBT modules and motor drive modules, ensuring efficient and stable operation of the system. They can also be used as on-board electronic circuits.

Lighting and Display

Alumina substrates can be used in high-power LED lamp beads to dissipate heat, helping to avoid light decay; while in laser diodes and displays, ceramic substrates can provide good electrical insulation and thermal management.

Aerospace and Military

Radar and satellite electronic devices require high-frequency, high-power, and highly reliable components, and alumina substrates can provide high insulation and thermal stability.

Êtes-vous inquiet au sujet du MOQ ?

Our Al2O3 substrates offer a special minimum order quantity (MOQ) of one piece to meet small order needs. Experience our service now.

Pourquoi choisir GORGEOUS ?

At GORGEOUS, quality control is our top priority. Every alumina substrate is manufactured to exacting customer specifications and undergoes multiple inspections and tests, from raw materials to finished product, to ensure consistent performance and reliable quality.

Our factory is certified to IATF 16949:2016 for the automotive industry and ISO 9001:2015 for international quality management systems. This not only demonstrates our commitment to quality, but also ensures we can provide our customers with high-standard customized solutions.

Nos réussites en matière de passeports Témoignages

We are very satisfied with this batch of customized alumina ceramic substrates and the project is progressing very smoothly.

James Walker

I believe we will continue to maintain this long-term cooperative relationship!

Sarah Wilson

The performance of GORGEOUS's alumina ceramic substrate exceeded our expectations and we were deeply impressed during the communication process.

Jonathan Miller

FAQ

What is an alumina substrate?

Alumina substrate is a base material made primarily of aluminum oxide. It offers high insulation, high thermal conductivity, high-temperature resistance, corrosion resistance, and good mechanical strength. It is commonly used as a support material for circuits and as an insulating and heat-dissipating material.

What are the advantages of alumina substrates in electronic products?

They are relatively low-cost and cost-effective. They offer excellent electrical insulation, ensuring safe and stable circuits. Their high thermal conductivity facilitates heat dissipation and extends device life. They are also resistant to high temperatures and corrosion, making them adaptable to complex environments. Their exceptional mechanical strength allows them to support precision components.

Can GORGEOUS ceramic substrates be customized?

Yes, we offer custom ceramic substrates in various thicknesses, sizes, and surface finishes. We provide the best design and custom solutions based on our customers’ application needs.