What if I told you that there is a material that can withstand the high temperature of cutting hardened steel like butter and melting most metals, and has three times the life of the current tool? Advanced ceramic metal composites (ceramets) are not just industrial materials. It is a game changer that is quietly revolutionizing manufacturing sites around the world.

What Are Ceramic-Metal Composites, and Why Should You Choose Them?

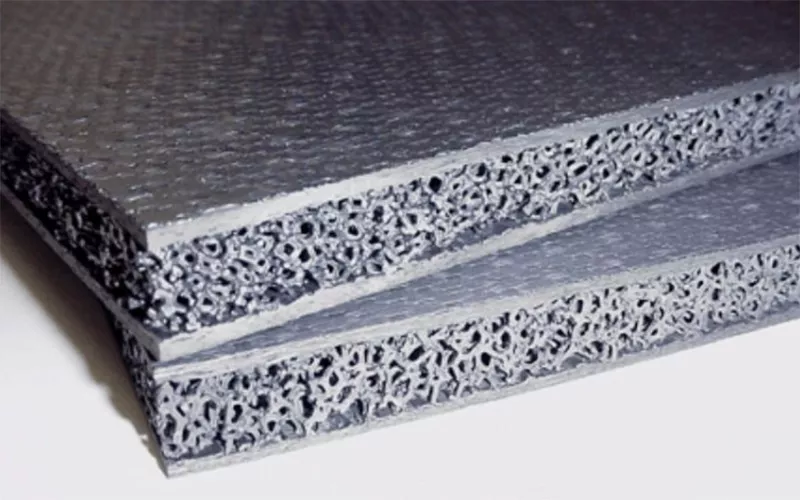

Ceramic metal composites (cermets) may be the solution you need if you are facing a problem of material corruption in harsh environments. Pure ceramics crack under stress, and the metal softens at high temperatures, but the ceramics have both advantages.

The secret of the cermet lies in its double nature. Imagine reinforced concrete. Ceramic particles provide high hardness and heat resistance, and metal matrix adds toughness and workability. With this combination, we can also respond to applications that destroy conventional materials.

For example, you know how difficult it is to process titanium alloys in the aerospace manufacturing industry. Using cermet cutting tools, these strong materials can be processed at high speeds while achieving the surface finish required by specifications.

How to Choose Premium Cermet Solutions for Your Critical Applications

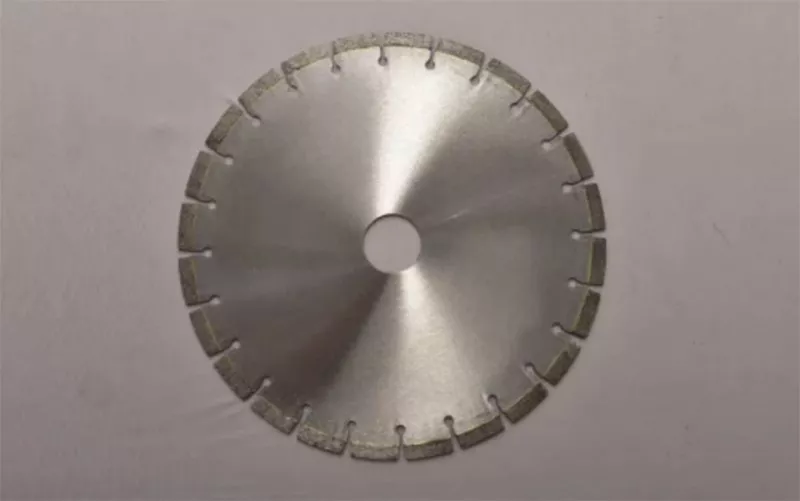

Solving Your Cutting Tool Challenges

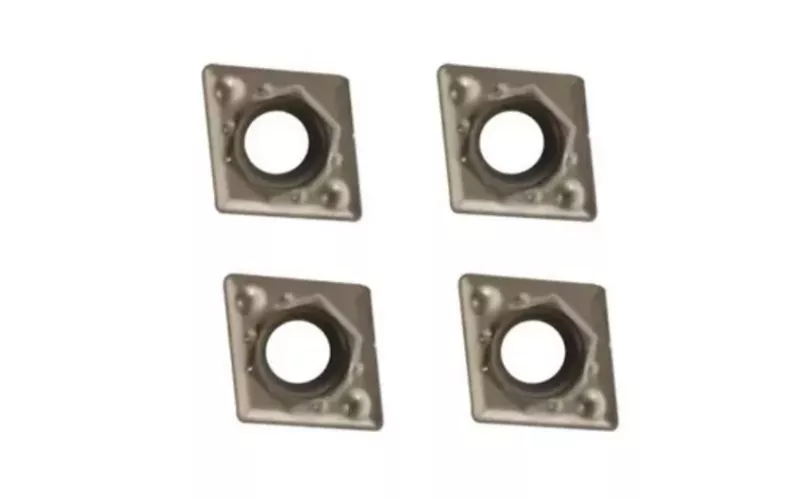

Are you tired of frequent tool changes hindering production schedules? Cermet materials for cutting revolutionized the way manufacturers work on precision cutting.

Let’s share the real case:

Precision parts manufacturers faced problems with frequent tool replacement disrupting production schedules. As a result of switching to ceramic tools with advanced titanium carbon nitride (TiCN) composition, the tool life is greatly extended and the surface finish quality is improved. What is the impact on your profits? In addition to a significant monthly reduction in tool costs, productivity increases due to reduced production disruption.

Le best cermet for cutting tools depends on your specific application:

-

If you’re machining steel parts: Choose TiC-based cermets for optimal wear resistance

-

For interrupted cuts: Go with TiCN-based grades that handle shock loading better

-

When surface finish is critical: Select fine-grained cermet grades with optimized chip breakers

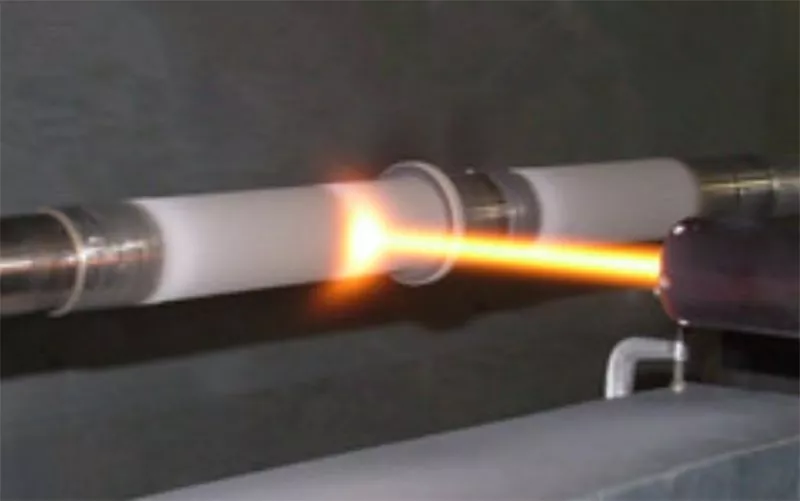

Protecting Your Equipment with Industrial Coatings

Is equipment wear eating into your maintenance budget? Cermet thermal spray coatings provides a cost-effective solution that greatly extends the life of components.

The following is a success story that you can sympathize with:

There was a re-manufacturer of automotive engines facing early wear problems on valve seats for parts. Ceramet coating using advanced plasma injection technology has dramatically improved the life of components. As a result, customer complaints and warranty claims were greatly reduced.

Your cermet coating options include:

-

For high-temperature applications: Chromium carbide-nickel chrome cermets

-

Chemical resistance needs: Tungsten carbide-cobalt compositions

-

Electrical applications: Titanium carbide-nickel for conductive wear resistance

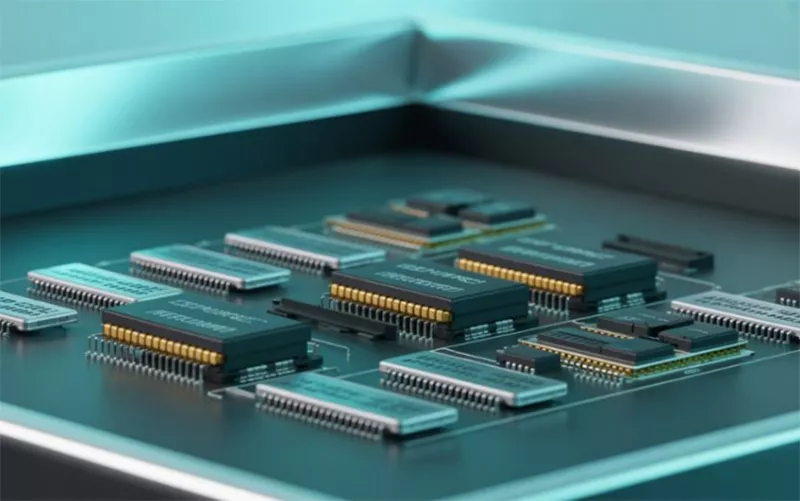

Enhancing Your Electronic Designs

Do you design electronic devices that operate in harsh environments? Ceramet electronic components provide the reliability required for products that are not allowed to fail.

Actual Challenge Example:

Medical device manufacturers needed a heating element that could maintain accurate temperature accuracy during long operation periods. Their solution was a cermet heating element using advanced aluminum oxide ceramic with special metallization treatment. Benefits of this approach: These elements show excellent temperature stability and outstanding durability.

Key applications where you’ll find cermets essential:

-

Precision resistors: When you need stable resistance values across wide temperature ranges

-

High-frequency applications: Where parasitic capacitance must be minimized

-

Power electronics: When thermal management is critical for reliability

Making the Right Choice: Cermet vs Traditional Materials

Still wondering if investing in cermets is worth it? I will explain it compared to what I am currently using.

Example of optional evaluation with manufacturers:

Tool costs were rising sharply during the machining of cast iron brake rotors. The surface finish requirements were strict and the tool performance was not stable. We conducted a comprehensive evaluation comparing different material options:

|

Your Concerns |

Cermet Performance |

Tungsten Carbide |

What This Means for You |

|

Tool Life |

Longer |

Normal |

Savings |

|

Surface Finish |

Smooth |

Rough |

Quality |

|

Speed Capability |

Faster |

Slower |

Productivity |

|

Cost Effectiveness |

Investment |

Cheap |

Profitable |

Realistic consideration:

The cost investment in ceramic composite tools are high, but the cost per part is beneficial since they have longer life durability and are more productive.

The reality check: Although cermet tools cost more to buy, they frequently end up costing less per piece with longer life at increased production.

Under what conditions are cermets to be preferred to carbide?

-

When you have constant operations such that when you change tools, production is disturbed then you use it.

-

They are shrinking when the demands on surface finish are tightening

-

In case you are machining faster in order to be more productive

-

When the tools that you are currently using are not up to specification

Why cart with carbide: Interrupted cuts that are heavy in nature, knuckling machining or in instances where toughness rather than wear resistance is important.

Your Guide to Selecting the Right Cermet Grade

Spinning over technicalities? There is no need to worry, though, because I will explain step by step how you can make the proper decision when it comes to correctly selecting the cermet that best fits your application.

The three easy questions to answer are:

-

What is your effective temperature? This decides what stage of ceramics you take on.

-

What magnitude of shock loading will there be? This affects the metal matrix that you choose.

-

What is more important, toughness or wear resistance? This directs your balance of composition.

Your Composition Roadmap

You are new at cermets? Well, this is where you start:

-

In general machining of steels: Use TiC-Ni based cermets

-

Especially when the additional strength is required: TiCN-Ni grades it is

-

To be resistant to high temperatures: Choose Al₂O₃ metal composites

It is all in your application. In automotive manufacturing, you have to know where to get production that needs to be consistent over expansive quantities. In the case of aerospace applications, the surface finish and dimensional accuracy are more important than cost. The biocompatibility may be necessary in medical devices manufacture.

Your Practical Guide to Sourcing and Pricing

Ready to buy but not sure what to expect? Let me give you the insider knowledge that’ll help you get the best value.

Understanding Real-World Pricing

Most cermet pricing depends heavily on the complexity of the composition as well as the quantity and needs of the order being fulfilled. The price that you pay will vary with your material type, volume of your order, your custom machining requirements, and the level of quality certifications.

One buying error which I observe most frequently is this: Buyers concentrate themselves on the material cost and disregard the processing charges. Smart approach? Get comprehensive quotes that include your finished specifications.

How to Evaluate Cermet Suppliers

What you should do: Order small sample quantities out of 2-3 suppliers. Before spending considerable budgets on the concerned materials, test them in the actual use.

Questions to be asked to any supplier:

-

Do you have certified test reports per batch?

-

How many days on average of custom compositions do you have?

-

Do you give technical assistance in parameters optimization?

Warning signs: Cermet suppliers that cannot give you a technical data sheet, that refuse to examine their quality systems, that are pushy to give you immediate answers without appropriate consideration.

Case Studies: Industrial Success Stories

Manufacture of aerospace parts

One of the leading companies producing major turbines obtained a substantial increase in component life by changing conventional coating technology to cermet thermal spray technology. The composite of ceramic and metal was the best thermal barrier and achieved high bond strength with regard to thermal cycling.

Production of the automotive engines

An automotive manufacturer who has used cermet cutting tools in machining engine blocks has experienced a massive decrease in the frequency of tool changes and better quality of surface finish, which has led to significant savings in the annual budget of their production line.

Electronics Excellence in Manufacturing

A manufacturer of semiconductor equipment incorporated cermet heating elements which provided very uniform heating and processing temperatures throughout processing chambers, and cermet heating elements lasted 3 to 4 times longer than metallic heating elements.

Conclusion

Ceramic-metal composites are proven solutions for manufacturing challenges. From cermet cutting tools to protective coatings that extend the life of the equipment, these materials offer quantifiable benefits. Starting with small tests and working with experienced suppliers, you can achieve the performance improvements your business needs.

Are you ready to consider a cermet solution that suits your application? Contact a certified ceramic manufacturer for technical consultations, material samples and custom engineering support to maximize the performance benefits these advanced materials offer.