Comprometidos em fornecer a você personalização especial de tamanho e formato e solucionar diferenças de cores em lotes, fornecedor de braço de cerâmica!

Fornecedor de braço de cerâmica/efetor final de cerâmica

Personalize sua cerâmica

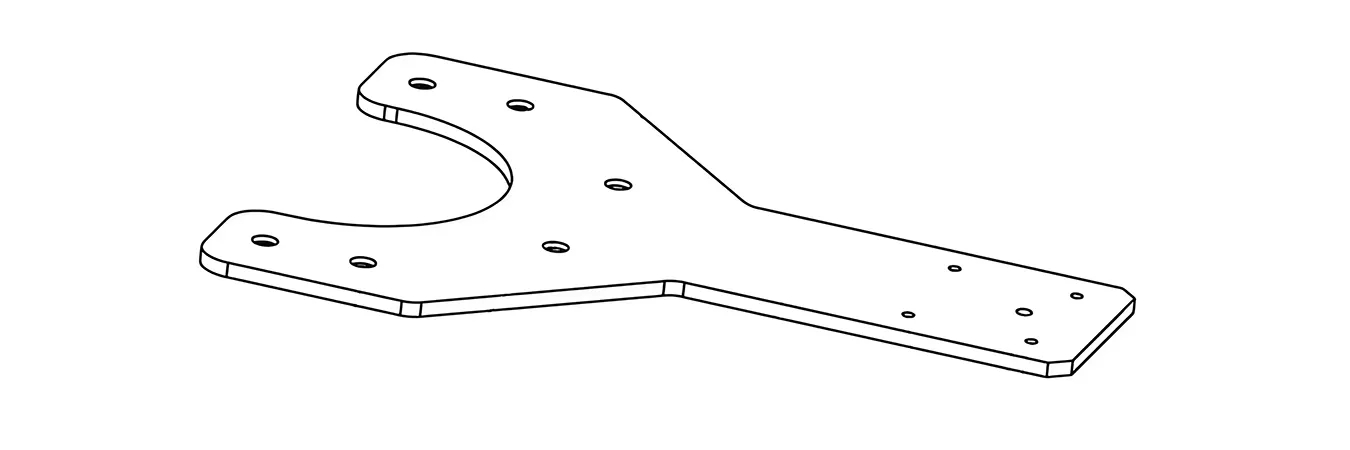

Descrição do braço de cerâmica

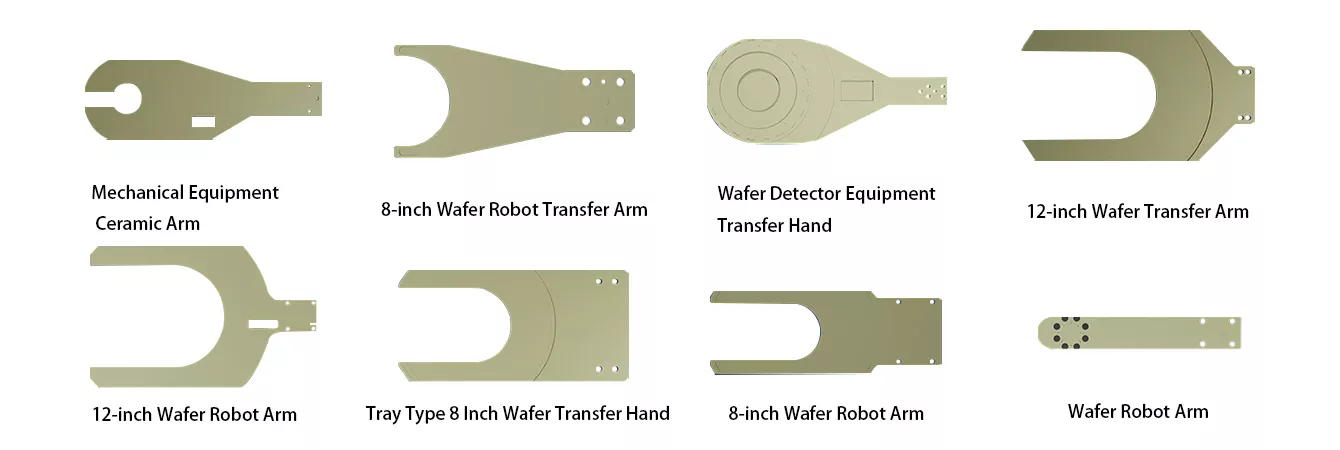

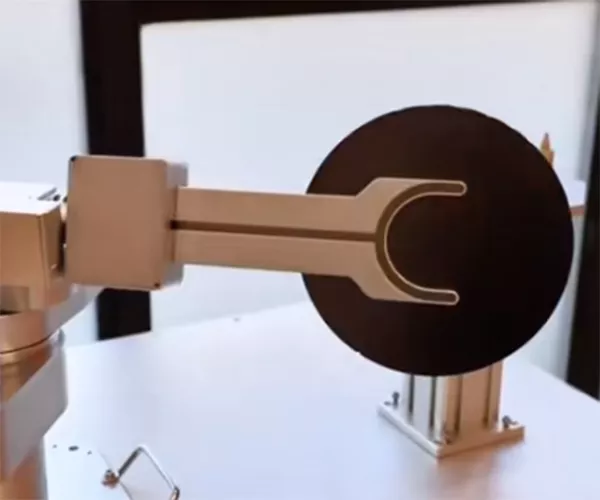

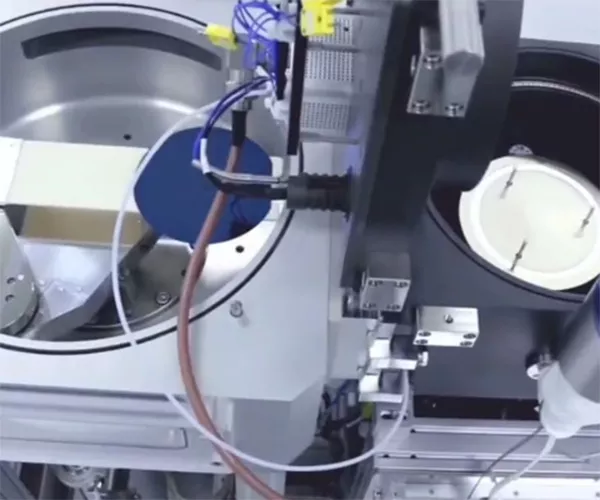

Braços robóticos de cerâmica, também conhecido como dedos robóticos de cerâmica, bandejas de wafer, braços robóticos de wafer redondo, etc., são usados principalmente para o transporte e manuseio de equipamentos semicondutores e são responsáveis pela entrega de wafers de silício em locais designados.

LINDOS recursos do produto:

▫️Alta precisão do produto

▫️Excelente estanqueidade ao ar

▫️Boa resistência a altas temperaturas

▫️Resistividade de superfície controlável

▫️Forte resistência a ácidos e álcalis e resistência à corrosão, adaptável a vários ambientes extremamente adversos

🔷Teste de autoaperto: desligue a fonte de ar de vácuo, pressão negativa –85 Kpa para -80Kpa, por mais de anos 60

🔷Teste de adsorção de wafer: desligue a fonte de ar de vácuo, pressão negativa -80Kpa para -25 Kpa, por mais de 35s

Garantia de fabricação e tempo de envio

A GORGEOUS é uma fabricante líder de cerâmicas para processamento de wafers semicondutores. Nós temos 15 Anos de tecnologia e experiência na fabricação de cerâmicas avançadas, e estamos constantemente otimizando e aprimorando o processo de fabricação de cerâmicas semicondutoras. Podemos personalizar diversos componentes para você, como braços cerâmicos, efetores terminais de robôs, mandris de wafers cerâmicos, etc.

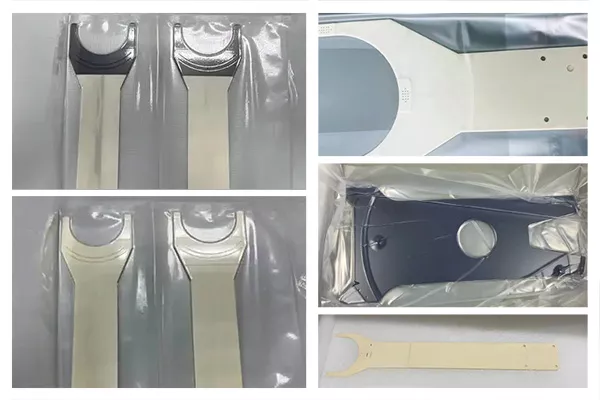

A embalagem do braço de cerâmica pode ser baseada em suas necessidades, usando materiais rígidos e ecológicos ou proteção de espuma macia.

Nossas cerâmicas são enviadas para todo o mundo, e o transporte depende da sua localização. Produzimos rapidamente para você, de acordo com o seu plano, e selecionamos o melhor método de transporte. O frete aéreo mais rápido da América do Norte chega em 7 dias.

A GORGEOUS opta por cooperar com diversas empresas líderes em logística, incluindo:

- MSC (Companhia de Navegação do Mediterrâneo)

- Maersk

- CMA CGM

- COSCO

- Hapag-Lloyd

- DHL

- UPS

- FedEx

- TNT

Trabalhamos com vários transportadores de carga para garantir opções de envio eficientes a preços mais baixos, entrega no prazo, e sem taxas ocultas!

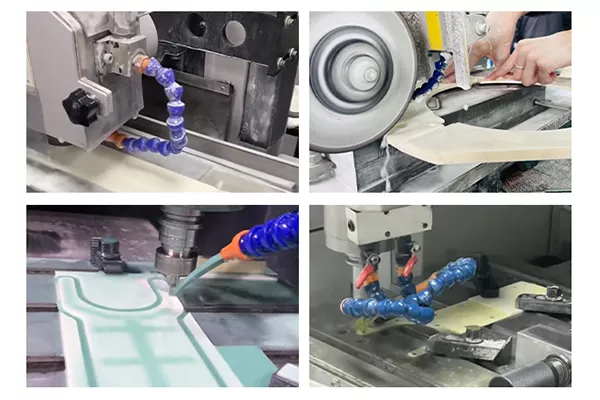

Fabricação

Embalagem

Carregando

Transporte

Desempenho principal do braço cerâmico/efetor final cerâmico

Leve

Resistente ao desgaste

Resistente à corrosão

Resistência a altas temperaturas

Isolamento forte

Referência de precisão de produto personalizável e LINDA

| Mínimo | Máximo | |

| Espessura total | 1,5 mm | 4 mm |

| Espessura da cavidade | 0,5 mm | 0,7 mm |

| Espessura da lacuna entre a cavidade e a superfície | 0,5 mm | – |

| Largura da cavidade | 2 mm | 6 mm |

| Limite de distância da borda | 2 mm | – |

| Tamanho do poro de adsorção | 0,5 mm | – |

| Comprimento do Vazio | – | 360 mm |

*A precisão específica precisa ser determinada de acordo com o material real do produto, formato e requisitos do processo.

Personalize vários tipos de braço cerâmico semicondutor

![]()

![]()

![]()

![]()

![]()

Parâmetros e seleção de materiais de braço personalizados

| Item | Unidade | Zircônia |

| Densidade | g/cm3 | 6.0 |

| Teor de zircônia | % | 94.4% |

| Tamanho do grão | µm | 0.5 |

| Dureza Rockwell (45N) | R45N | 78 |

| Dureza Vickers (Carga 500g) | GPa (kg/mm)2 ) | 11,5 (1175) |

| Resistência à flexão (20℃) | MPa | 800 |

| Resistência à compressão (20℃) | MPa | 2000 |

| Resistência à fratura (20℃) | MPam1/2 | 9.0 |

| Condutividade térmica (20℃-400℃) | W /(mk) | 2.5 |

| Coeficiente de Expansão Térmica | 10-6 /℃ | 9.6 |

| Resistência ao choque térmico | △T℃ | 250 |

| Propriedade | Unidade | AL2O3 99.7 | AL2O3 99.5 | AL2O3 99 | AL2O3 95 |

| Pureza | — | 99.7% | 99.5% | 99% | 95% |

| Densidade | g/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| Resistência à flexão | MPa | 375 | 370 | 340 | 304 |

| Resistência à compressão | MPa | 2450 | 2300 | 2250 | 1910 |

| Módulo de elasticidade | GPa | 380 | 370 | 330 | 330 |

| Resistência à fratura | MPam1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| Dureza | HRA | 91 | 91 | 90 | 89 |

| Dureza Vickers | HV1 | 1600 | 1550 | 1450 | 1400 |

| Coeficiente de Expansão Térmica | 10- 6 K-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| Condutividade térmica | Com mk | 32 | 32 | 25 | 25 |

| Estabilidade ao Choque Térmico | △T.℃ | 220 | 220 | 200 | 200 |

| Temperatura máxima de operação | °C | 1750 | 1750 | 1700 | 1500 |

| Resistência de volume a 20℃ | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| Rigidez Dielétrica | kV/mm | 22 | 20 | 16 | 15 |

| Constante Dielétrica (temperatura ambiente) | / | 10 | 11 | 11.5 | 11 |

| Fator de perda dielétrica em MHz | tan δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

| Item | Unidade | Nitreto de silício |

| Densidade | g/cm3 | >3.2 |

| Dureza | – | HRA90 |

| Dureza Vickers (Hv50) | HV0,5 | >1550 |

| Módulo de Elasticidade | GPa | 290 |

| Resistência à flexão | MPa | >600 |

| Resistência à compressão | MPa | 2500 |

| Resistência à fratura | MPam1/2 | >6.0 |

| Temperatura Máxima de Uso | °C | 1200 |

| Condutividade térmica | W /(M·K) | 15-20 |

| Coeficiente de Expansão Térmica | 10-6/℃ | >3.1 |

| Resistência ao choque térmico | △T℃ | 500 |

| Capacidade térmica específica | kJ/kg·K | 700 |

| Rigidez Dielétrica | kV/mm | 1 |

| Constante Dielétrica | er | – |

| Resistividade volumétrica a 20℃ | Ω.cm | 1,0×1012 |

Referência de tamanho padrão do braço/efetor final de cerâmica

Braços/efetores de cerâmica são componentes-chave usados para manusear wafers na fabricação de semicondutores. Podemos personalizá-los de acordo com o tamanho do wafer, o tipo de equipamento e os requisitos do processo. Aqui estão alguns tamanhos padrão comuns de braços cerâmicos para sua referência!

Escolha o comprimento do braço de cerâmica de acordo com o wafer:

❇️Wafer de 6 polegadas (150 mm): Comprimento do braço: aproximadamente 200-250 mm

❇️Bolacha de 8 polegadas (200 mm): Comprimento do braço: aproximadamente 250-300 mm

❇️Wafer de 12 polegadas (300 mm): Comprimento do braço: aproximadamente 350-400 mm

❇️Wafer de 18 polegadas (450 mm): Comprimento do braço: aproximadamente 500-550 mm

Largura e espessura do braço de cerâmica

❇️Largura: Tipicamente 20-50 mm, dependendo do tamanho do seu wafer e da capacidade de carga do braço necessária.

❇️Grossura: Tipicamente 5-15 mm, para garantir resistência e rigidez adequadas e reduzir o peso.

Design da extremidade do braço

❇️Design do garfo: comumente usado para manusear wafers, a largura e o espaçamento dos garfos correspondem às ranhuras da caixa do wafer

❇️Design de ventosa a vácuo: pode absorver diretamente o wafer, o tamanho comum da ventosa é 10-20 mm

❇️Design de fixação de borda: usado para processos especiais, a largura da área de fixação é 5-10 mm

Quais são os usos dos braços de cerâmica?

Braço robótico industrial

Braços de cerâmica são usados em robôs industriais de alta precisão, resistentes ao desgaste e à corrosão, e podem funcionar de forma estável em alguns ambientes de processamento de precisão e alta temperatura.

Fabricação de semicondutores

No processo de fabricação de chips, wafers de silício precisam ser transferidos entre diferentes etapas do processo (como litografia, gravação, deposição, etc.), e braços de cerâmica podem atuar como manipuladores de manuseio em um ambiente sem poeira.

Fabricação de eletrônicos

Braços cerâmicos para fabricação eletrônica são adequados para processos com altos requisitos de limpeza, como revestimento a vácuo, fabricação de chips e fabricação de displays OLED. Eles podem evitar a influência da expansão térmica de materiais metálicos e melhorar a estabilidade.

Pesquisa científica

Em equipamentos de laboratório que exigem resistência à corrosão e ambientes de alta temperatura, braços cerâmicos podem ser usados em áreas como síntese química, experimentos de plasma e pesquisa de supercondutividade.

Indústria alimentícia e farmacêutica

Materiais cerâmicos não contêm precipitação de íons metálicos e são adequados para áreas como processamento de alimentos e embalagens farmacêuticas, que exigem limpeza de material extremamente alta.

Serviço completo de fabricação de braços cerâmicos

15+ Anos de experiência. Alta precisão e design OEM. Equipe profissional de P&D. Preço competitivo.

O braço de cerâmica/efetor final de cerâmica se desgastará com o tempo?

Sim, o braço de cerâmica se desgasta com o tempo, especialmente em ambientes agressivos e agressivos. Mas não se preocupe muito, a cerâmica é um material muito duro e durável. Desde que seja bem conservado, você pode usá-lo por muitos anos.

O que causaria a quebra de um braço de cerâmica?

Mudanças bruscas de temperatura podem causar choque térmico e quebrar o braço cerâmico. Sobrecarga, colisão ou impacto severo além da capacidade nominal também podem causar ruptura.

Com que frequência você deve verificar seu braço de cerâmica?

Inspeções frequentes semanais permitirão que você detecte problemas precocemente. Os braços de cerâmica podem se desgastar, rachar ou se soltar após o uso prolongado. Recomendamos que você realize manutenções regulares.