ジルコニアセラミックチューブ

GORGEOUS zirconia tubes are made from high-quality alumina and are available in a variety of custom purities and sizes.

High Quality Zirconia Tube

カスタム加工サプライヤー

Zirconia Tube Description

GORGEOUS can provide customers with complete zirconia ceramic tube manufacturing services. We are proficient in a variety of advanced processes such as isostatic pressing, slip casting, dry pressing, CNC precision machining, polishing and high-temperature sintering to ensure that each product reaches the industry-leading level and accurately meets the application needs of customers.

Zirconia ceramic tubes are widely used in high-strength mechanical components, high-speed bearings, thermocouple protection tubes, chemical pipelines, analytical instruments, fuel cell systems and other fields. Its outstanding mechanical strength, wear resistance, corrosion resistance and thermal stability make it still perform well under harsh working conditions.

In addition, the low thermal conductivity and good insulation properties of zirconia also make it an ideal choice for certain specific insulation and heat insulation applications.

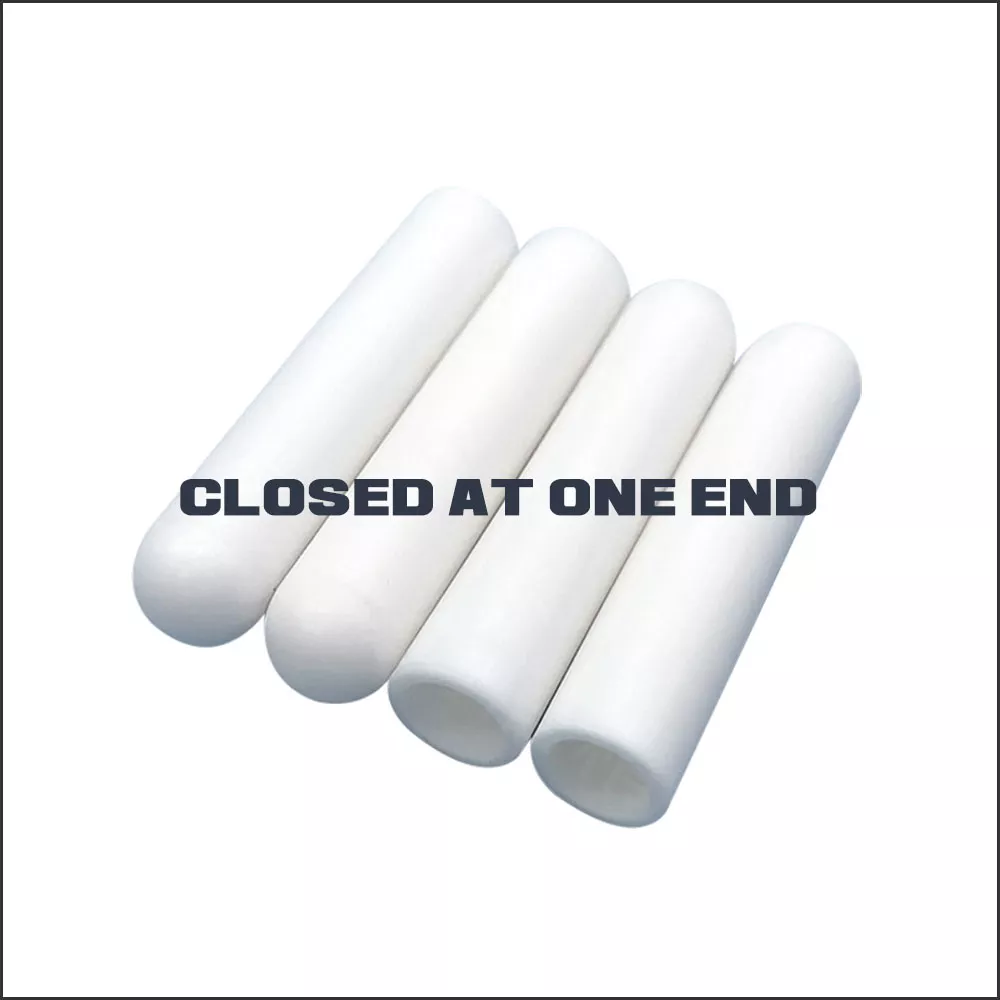

GORGEOUS customizes zirconia ceramic tubes according to the specific needs of customers. Whether it is a complex inner hole structure, precise wall thickness control, or special-shaped geometric design, our professional team can provide you with efficient solutions.

If your project requires wear-resistant, high-temperature-resistant, and corrosion-resistant zirconia ceramic tubes, please feel free to contact us to help you achieve the dual goals of product performance and quality.

Supply Various Shapes of Zirconia Ceramic Tubes

顧客のニーズに合わせてカスタマイズされたソリューションを提供する

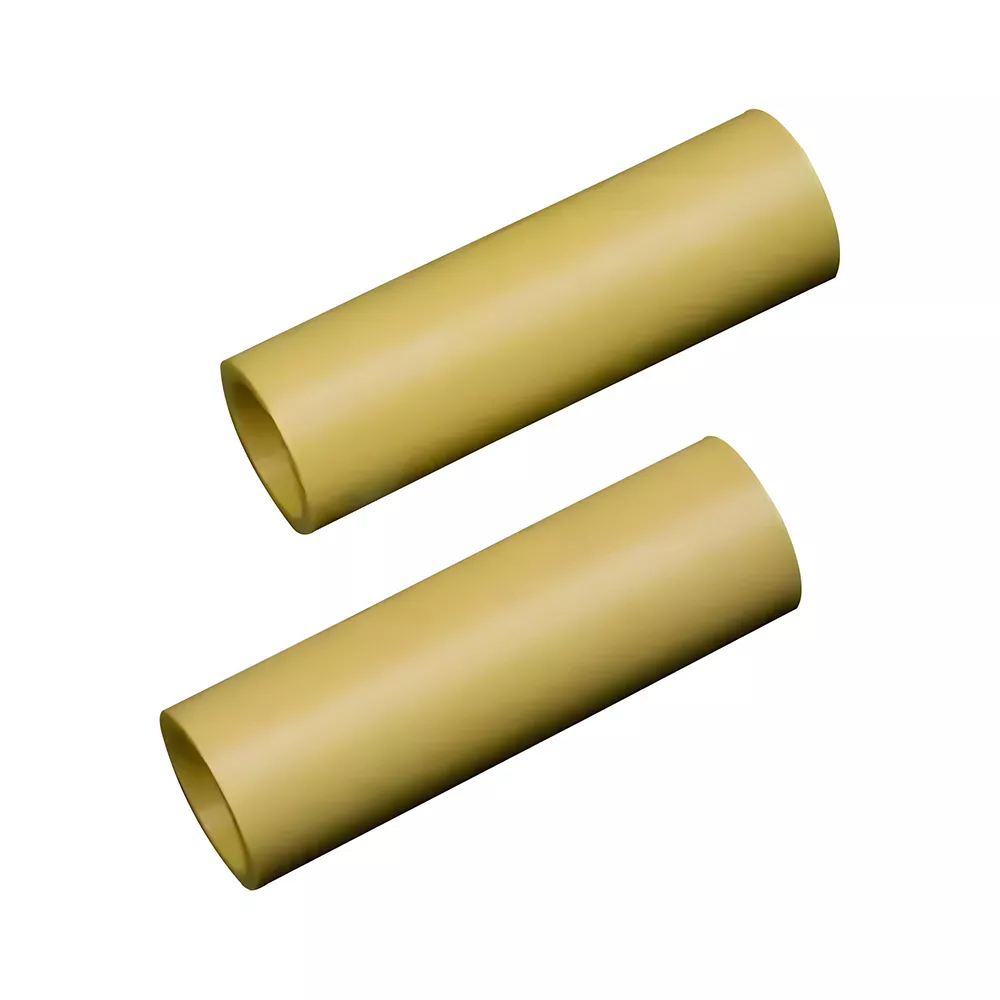

Supply Different Types of Zirconia Tubes

Note: YSZ is the material with the best bending strength among all the zirconia-based materials we supply. However, YSZ tubes are very brittle and you should be careful when using them as processing tubes.

In addition, the heating and cooling speeds should be as slow as possible (usually <5℃/min for heating at temperatures of 800℃ and above, and <2℃/min for temperatures above 1500℃)

YSZ Tube

8 mol% Y₂O₃ stabilized zirconia tube is resistant to high temperatures, has stable chemical properties, and has the best bending strength among zirconia-based materials.

Black Zirconia Tube

Adding specific elements, such as cerium oxide, yttrium oxide, chromium oxide or carbide, gives it a unique appearance and greater resistance to light pollution.

Mg-FSZ Tube

MgO-stabilized zirconia tubes have good thermal shock resistance and low cost, and are often used in high-temperature structural ceramics in the metallurgical industry.

Y-TZP Tube

3 mol% Y₂O₃ stabilized zirconia tube, phase transformation toughening, high bending strength, high fracture toughness and wear resistance, suitable for precision parts.

ジルコニアセラミックチューブの利点

High Flexural Strength

破壊靭性

耐食性

Low Thermal Conductivity

Mechanical Properties of Zirconia Tubes

| 名前 | ジルコニア | |||

| 密度 | g/cm3 | 6.02 | ||

| ヤング率 | GPa | 200 | ||

| 破壊靭性KIC | MPa m1/2 | 17 | ||

| ポアソン比 | – | 0.3 | ||

| 圧縮強度 | MPa | 2000 | ||

| 曲げ強度 | MPa | 1200 | ||

| 硬度 | GPa | 13 | ||

アルミナセラミックチューブの用途

工業製造業

In the industrial manufacturing industry, the high hardness and low friction coefficient of zirconia tubes are very suitable for replacing metals in various pumps, valves, and shaft applications.

よく使用される用途: Wear-resistant bushings, shaft sleeves, ceramic nozzles, insulation pipes, high-temperature pipe linings.

電子工学と電気工学

Zirconia is used as an insulator and can be used in high-frequency, high-voltage equipment components, such as for encapsulating thermocouple probes.

よく使用される用途: Electrical insulation tubes, thermocouple protection tubes, vacuum equipment components

医学および生物学

Zirconia has excellent biocompatibility and is often used in medical bioengineering equipment components and implants.

よく使用される用途: Bioceramic sleeves, laser beauty probe protective sleeves, dental equipment pipelines.

自動車と航空

Zirconia tubes are suitable for high temperature and highly corrosive working environments. In the automotive and aviation industries, they can be used to encapsulate oxygen sensor elements, thermal insulation components, etc.

よく使用される用途:Automotive oxygen sensors, exhaust temperature sensor sheaths, fuel cell isolation components.

MOQ について心配ですか?

少量生産のお客様のニーズにお応えするため、1個からの最小注文数量(MOQ)も承っております。まずはお気軽に当社のサービスをお試しください。

GORGEOUSを選ぶ理由

GORGEOUS focuses on quality control to ensure that every zirconia tube product meets customer requirements. Our quality inspection process is strict and meticulous. From raw materials to finished ceramic products, every step is precisely inspected and tested.

In addition, the GORGEOUS factory has passed the IATF16949:2016 automotive industry quality management system certification and ISO9001:2015 quality management certification, and is able to provide customers with the best quality customized services.

パス成功例 お客様の声

GORGEOUS's zirconia tubes are very competitively priced and of superior quality. We have established a long-term and reliable cooperative relationship with them.

Michael

GORGEOUS custom-made zirconia tubes are exactly as per our drawings. They are excellent in precision and appearance, and are normally equipped with factory equipment.

David

GORGEOUS のサービスは素晴らしく、荷物は迅速かつ安全に到着しました。

John

よくある質問

What is the difference between zirconia ceramic tubes and other ceramic tubes?

Zirconia ceramics have stronger toughness and fracture resistance than other ceramics. Compared with alumina, zirconia is more resistant to cracking and has better mechanical impact toughness. Compared with silicon carbide and silicon nitride, zirconia has poorer heat resistance under mechanical load.

What are the benefits of zirconia ceramic tubes?

Excellent mechanical strength - Zirconia tubes have excellent bending and compressive strength, making them ideal for load-bearing applications.

High fracture toughness - Zirconia is different from other ceramics and can resist cracks and mechanical impact.

Excellent wear resistance - Suitable for various high wear environments such as seals, plungers or bushings.

What are the disadvantages of zirconia ceramic tubes?

Pure zirconium oxide tends to undergo phase changes, requiring the use of stabilization agents such as yttria, adding complexity.

Density is higher than most ceramics, a limitation in some weight-sensitive applications.

In what fields can zirconia ceramic tubes be used?

Industrial machinery (high-pressure pump pipes, plungers, sealing rings): suitable for high-friction, corrosive liquid delivery systems

Chemical and material processing (corrosion-resistant transmission pipelines): used for the transportation of strong acids, strong alkalis or high-temperature corrosive gases/liquids

Medical and biotechnology (implant-level product development experimental pipelines): biologically inert and non-toxic

Electronic and electrical insulation (high-voltage electrical insulation pipes, thermal insulation sheaths): used for high-temperature/high-voltage power equipment

Automotive and energy industries (thermal barrier coating cores/insulated conduits): used for engine and turbine systems

Special fields (laser system guide tubes): suitable for high-precision laser processing equipment