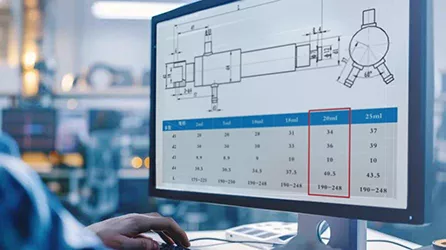

当社は、高精度で複雑な部品を製造するための包括的なカスタム製造サービスを提供しています。

さまざまなアプリケーション向けのカスタム先進セラミックソリューションの設計および開発の経験。

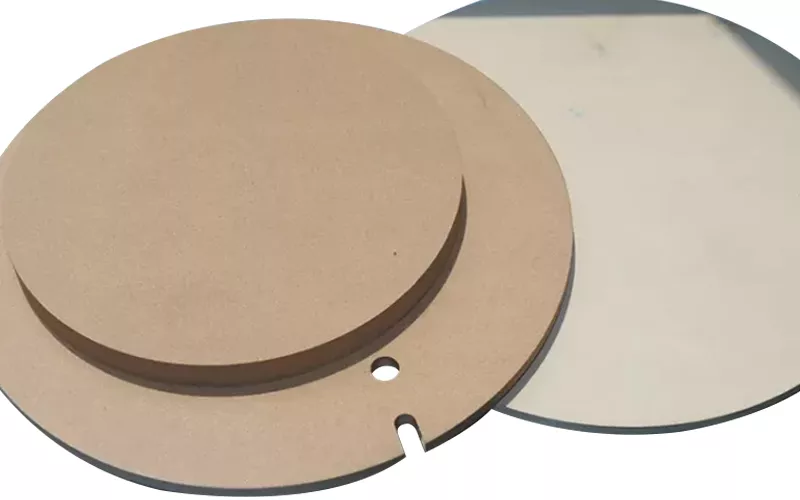

当社は高精度のテクニカルセラミックのフライス加工、研削、研磨において豊富な経験を持っています。

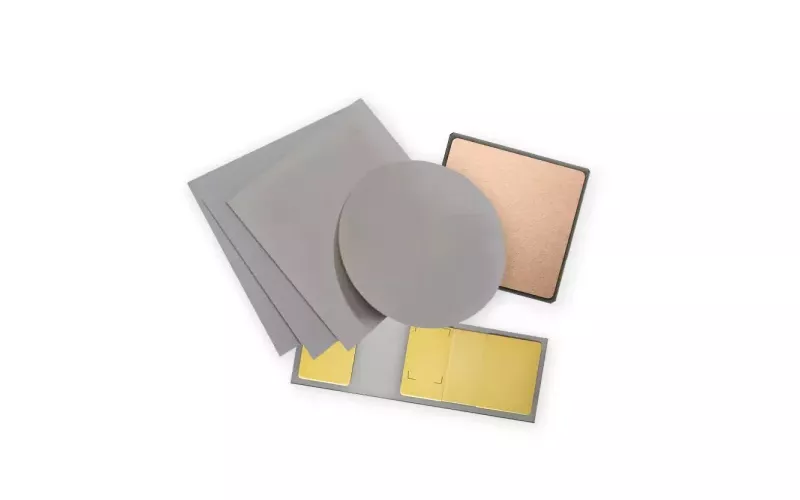

カスタマイズ可能なセラミック材料

GORGEOUS CERAMICS(GGS)は、アルミナ、酸化ジルコニウム、窒化アルミニウム、窒化ケイ素、窒化ホウ素、炭化ケイ素、炭化ホウ素、酸化ベリリウムなど、幅広い高性能セラミック材料を取り揃えています。GORGEOUS CERAMICS(GGS)は、お客様のアプリケーション要件に基づいて最適な材料ソリューションを選択し、性能とコストの最適なバランスを実現できるようお手伝いいたします。

GORGEOUS ベストセラー製品!

当社は、様々な業界の高度なセラミックニーズにお応えします。標準的な高温・耐腐食性セラミック部品、半導体業界向けの高精度セラミック部品、高速応答性と高いエネルギー効率を備えたセラミックヒーターなど、お客様のご要望に応じて、実績のある高性能なカスタマイズソリューションをご提供し、設計から量産までシームレスな移行を実現します。

以下は、GORGEOUS CERAMICS (GGS) のベストセラー製品の一部です。

セラミックヒーター

セラミック点火装置

セラミック基板

半導体セラミックス

マイクロポーラスセラミックス

フィードスルー

GORGEOUS CERAMICS (GGS)

– 信頼できるパートナー

世界中で販売されている製品

GORGEOUS CERAMICS (GGS) は中国に本社を置き、顧客に迅速で高品質なオンデマンド製造ソリューションを提供することを目指し、高度なセラミック製品を世界中に輸出しています。

中国における大手先端セラミックサプライヤーとして、当社は世界規模の配送をサポートし、北米とヨーロッパの主要地域に最短 3 ~ 10 日で配送します。

当社のプロジェクトエンジニアは全員、英語でのコミュニケーションに堪能です。平日は迅速に対応し、タイムゾーンを越えてお客様のニーズにシームレスに応え、試作から納品まで、プロジェクトのスムーズな進行をサポートします。

30,000㎡ 20,000+ 120+

Factory floor area Global customers The country of service

新製品開発からソリューションまで

GORGEOUS CERAMICS (GGS) は、単なる製造サービスにとどまりません。設計、試作、生産、パッケージングに至るまで、製品開発サイクル全体にわたるソリューションを提供します。

さまざまな業界向けにカスタマイズされた先進セラミックス

当社のセラミック製品は、航空宇宙、自動車、半導体エレクトロニクス、機械、化学、医療分野など、幅広い用途に使用されています。

航空宇宙

自動車

エレクトロニクス

機械工学

医学

化学薬品

当社のセラミック製造アプリケーション

GORGEOUS CERAMICS (GGS) は、次のような構造、機械、部品を作成するためのカスタムセラミック製造サービスを提供しています。

お客様の声

GORGEOUS は私たちと非常にうまくコミュニケーションを取り、常に私たちのニーズを正確に理解し、タイムリーに応答してくれました。

カール

彼らの生産スピードは驚異的で、私たちの注文は常に時間どおりに納品され、品質も優れており、一緒に仕事をするのが楽しいです。

シェ・ザン

彼らのサービスには本当に満足しています!どんな問題でもすぐに解決してくれて、プロフェッショナルで効率的です。GGSに心から感謝します!

ハンス

関連リソース

Applications of Silicon Carbide Bearings and Shafts in High-Speed and Wear-Intensive Industries

Standard material-made bearings often fail in harsh chemical, advanced engineering, and fast-moving industries. Rather, silicon carbide bearings perform exceptionally well in these fields.Let’s explor…

Silicon Carbide vs Steel FGD Nozzles: Which Reduces Downtime?

Steel desulfurization nozzles fail in 6-12 months due to wear and clogging. Silicon carbide nozzles last 3-5 years with excellent corrosion resistance. This guide covers performance comparison, total …

Silicon Carbide Bulletproof Plate: Lightweight, Reliable & Safe

Your silicon carbide bulletproof plate offers exceptional hardness, low density, and great shock resistance. In your defense equipment manufacturing, SiC translates to superior, lightweight bulletproo…

クイック見積もりを送信

GORGEOUSが信頼される理由 1000+ 顧客ですか?

当社の工業用セラミック製造は、様々な業界、事業、プロジェクトに多くのメリットをもたらします。当社のサービスの利点をご紹介します。

手頃な価格で迅速な生産

GORGEOUSは、様々なセラミックの試作品から最終製品を迅速に製造できます。GORGEOUSは、高精度を確保しながら迅速な生産を実現します。また、大規模生産により、コスト効率の高いセラミック製造サービスも提供しています。

優れた強度対重量比

当社の高度な製造技術により、高品質かつ耐久性に優れたセラミック部品を製造できます。製造されるすべてのセラミック製品は、高い強度、耐傷性、耐腐食性を保証します。

幅広い素材と技術を使用

当社は、ノッチ、スロット、穴などの複雑な特徴を備えた複雑な部品の製造を可能にする、さまざまなセラミック材料製造技術の専門家です。当社の幅広いセラミック材料は、耐熱性、耐腐食性などにも耐えることができます。