Figure 1. Biomass stove bringing warmth to your home

Biomass stoves require a stable ignition to heat the house on a daily basis. Heating is disabled when the ignition device breaks down. The ceramic biomass igniters are 3-5 times longer than traditional components and use less power and ignite quicker. This guide will help you choose a biomass igniter suitable for the heating system.

What Makes Biomass Heating Different

Figure 2. Comparing pellet and wood stoves

Tuo biomass stove or boiler burn natural materials such as wood pellets, chips, corn and agricultural waste. Instead of running continuously like a gas system, biomass heating works only when necessary.

This frequent start and stop burden ignition parts. Every time the system starts, the ignition system heats rapidly to more than 1000 °C in just 60 to 90 seconds from room temperature. It is then cooled again after ignition.

Traditional ignition devices cannot withstand this load for long. It is consumed by repeated heating and cooling. In addition, biomass fuels produce ash and rapidly corrode conventional materials. If you’re replacing your igniter every year or two, it’s time to upgrade to materiali ceramici.

Why Ceramic Igniters Work Better

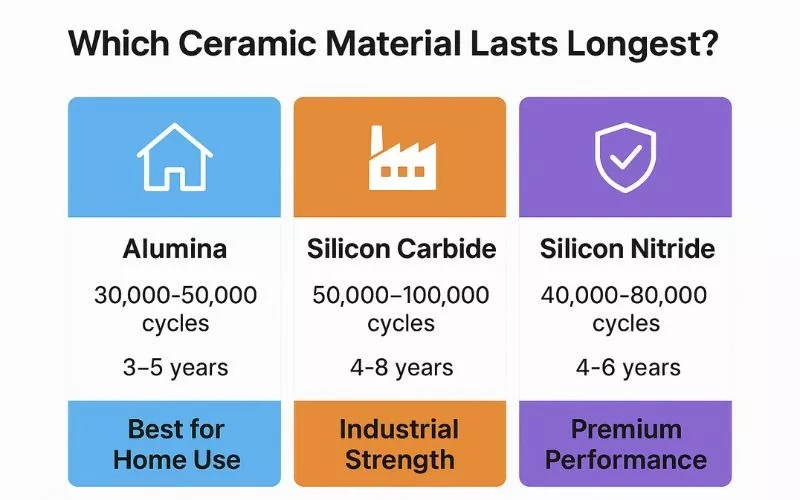

IL ceramic biomass igniters complete 30,000 to 100,000 ignition cycles before replacement is required. This is equivalent to three to eight years of reliable operation. Traditional parts wear out much faster.

The power consumption of ceramic biomass igniters is usually 150 to 300 watts. Old-style hot air blowers use 300-600 watts that’s double the electricity. A 250W ceramic unit running 4 times daily, the annual electricity cost is about $12. Using 500W blowers for the same task costs $24.

IL ceramic ignition system reaches 1000°C in 60-90 seconds and ignites biomass fuel quickly and completely. Clean combustion with little smoke and ash. Whether you burn premium wood pellets or agricultural waste, ceramic materials work reliably in all biomass stoves and boilers without reacting to minerals and ash in your fuel.

Ceramic igniters are in increasing demand across the globe. Actually, it can be seen that the market of the pellet stove itself will reach a mark of 11.4 billion in 2032 since more individuals are interested in heating components that really work.

Types Of Ceramic Materials: Which One Is Right For You?

Figure 3. A ceramic ignition rod up close

Not all ceramic igniters are the same. The material you choose affects how long it lasts, how much it costs, and whether it handles your specific heating conditions.

Alumina Ceramic: The Smart Choice For Most Users

Alumina is aluminum oxide ceramic (Al₂O₃). It is the most popular material because it provides you excellent performance at a reasonable price.

Performance Specifications:

-

Heat resistant temperature: up to 1400°C

-

Ignition cycle life: 30,000-50,000 times

-

Retail price: $35 to $65 per unit (wholesale: $12 to $25 for bulk orders)

-

Power consumption: 200 to 300 watts

When alumina is your best choice: You have a home pellet stove or small business heating system starting 2-6 times daily. Your fuel is decent quality wood pellets. You want reliable performance without spending too much.

Real example: A homeowner with a 15kW pellet stove gets 5-6 years from an alumina ceramic igniter with monthly cleaning. That’s about $10 per year.

There is a rapid conversion to the use of ceramic igniters by European house owners. Currently, more than 5.5 million pellet stoves are operating in Europe, and Italy has already put in place 200,000 new systems in the previous year alone.

Silicon Carbide: Built For Tough Industrial Use

carburo di silicio (SiC) is the most rugged option. It costs more but handles extreme conditions that destroy other materials.

Performance Specifications:

-

Operating at temperatures up to 1500 °C

-

Durability from 50,000 to 100,000 cycles

-

Retail price: $65 to $110 per unit (wholesale: $25 to $45 for bulk purchases)

-

Maximum resistance to ash and corrosion

When silicon carbide is best: Running commercial or industrial biomass boilers 8 or more times a day. Combustion of waste, wood waste and high ash mixed fuel. You need a biomass gasification boiler igniter that survives harsh chemical environments. Silicon carbide handles the acids and tar that destroy other materials in biomass gasification boiler systems.

Examples: The manufacturing plant that burns sawdust waste with 500kW boiler switches to silicon carbide, achieving a lifespan of 4-5 years per ignition device eliminating emergency service calls.

Silicon Nitride: Premium Performance For Variable Conditions

Silicon nitride (Si₃N₄) has the highest thermal shock resistance. Even sudden temperature changes do not break.

Performance Specifications:

-

Stable operation up to 1400-1500°C

-

40,000-80,000 cycles

-

Retail price: $80-120 per piece (wholesale: $30-55 for bulk purchases)

-

Ottima resistenza agli shock termici

When silicon nitride is best: Your area has frequent power outages forcing cold starts. When using multiple fuel types or available fuel per season. Your heating is in mobile applications like RVs or boats where vibration and temperature swings are constant.

Figure 4. Which material lasts the longest?

Where You’ll Use Ceramic Igniters

Ceramic igniters work in all types of biomass stoves and boilers, from small home units to large industrial systems. Here’s where you’ll use them:

Home Biomass Stove

Your home biomass stove (5-15kW) probably starts 2-4 times daily. The ceramic ignition system operates quietly, consumes less power and lasts for years. Most homeowners do not think about ignition equipment until the replacement time comes after 5-7 years.

Business biomass boilers

If you run a business with biomass boilers (50-300 kW),you can’t afford heating failures. Silicon carbide or high-grade alumina ignition devices handle 6-10 ignition times a day without problems.

Biomass gasification boiler

Tuo biomass gasification boiler converts solid biomass into gas and burns the gas. This creates harsh environments including acid and tar. A carbide ceramic ignition system is required for gasification. Regular materials break down quickly in these conditions.

Industrial equipment

In manufacturing, plants burn waste products in large biomass boilers (500 kW to 10 MW). Ceramic ignition devices reduce unexpected outages and that costs thousands per hour in lost production.

How To Buy The Right Ceramic Igniter

Figure 5. Different types of ceramic igniters

Match Power to Your System: Check the current ignition system wattage. The small home stove is 200-250W, medium business use is 250-350W, large industrial use uses 350-500W. Do not guess, too little power means slow starts.

Material selection: Alumina ceramic is the most cost effective for home use. If you run a business, spend more on carburo di silicio. The longer life pays back the higher cost.

Check Compatibility: The new ceramic ignition system must fit the existing mounting part. Please measure the length of the old ignition device, mounting hole diameter, wiring connection method, voltage (120V or 240V). If you can’t find an exact match, ask about a custom ceramic solution.

Find Certified Suppliers: Find a manufacturer with ISO 9001:2015 certification. Ask for test data indicating that the ignition device meets ASTM C1161 standards.

Compare total costs: Don’t just look at the purchase price. A $60 ceramic igniter lasting 6 years costs $10 per year. A traditional part costing $35 and lasting 2 years costs $17.50 per year. Even if the initial cost is high, ceramic can reduce costs in the long term.

What Good Ceramic Manufacturers Offer

High quality materials

Top manufacturers use high purity materiali ceramici. Always ask for material certifications and test data of the material. Low purity causes short lifetime and poor performance. Quality is more important than low price.

Proper Certifications

Check ISO 9001:2015 certification for quality control. Check CE, UL and RoHS compliance depending on the region. ISO 17885:2025 Thermal Cycle Standard proves that the ignition device can withstand repeated heating. These certifications ensure safety and reliability.

Customization Options

Special dimensions may be required for biomass boilers. Good suppliers offer custom length, different diameters and various wire types. Mounting brackets can also be customized. Ask about minimum order quantities, some require 500+ pieces for custom work, others work with small batches.

Technical Support

Real technical support makes a difference. Choose a supplier that provides telephone and email support, installation guides, and troubleshooting assistance. Warranty coverage should be 2+ years minimum. This enables investment protection in case of problems.

Fast delivery and availability

Check if suppliers keep common sizes in stock. Lead time is important for emergency repair of heating systems. Reliable manufacturers maintain stock and ship quickly. Check the delivery time before ordering.

Testing and Quality Control

All ceramic ignition devices should be tested before shipment. Quality is ensured by heating time, resistance value and heat resistance test. Manufacturers with computerized testing systems can detect defects early. This reduces the failure rate after installation.

For ISO certified ceramic ignition equipment and custom solutions, GGSCeramic manufactures materiali ceramici avanzati including allumina E silicon carbide parts. With engineering expertise and a high-quality production system, the company supports biomass heating manufacturers and end users around the world.

Common Mistakes When Buying To Avoid

Do not make the following errors when purchasing ceramic ignition devices:

-

Prioritize price over quality: A $40 igniter lasting 5 years is better than the $25 part that breaks down in one year.

-

Ignore voltage requirements: Incorrect voltage (120V vs 240V) instantly damages ignition equipment and voids warranty.

-

Purchase without authentication:Uncertified ignition equipment creates fire hazards and voids equipment warranty

-

Omitting Compatibility Check: Be sure to measure the dimensions of the old ignition device (length, diameter, mounting method) before ordering

Easy Maintenance Tips

Figure 7. Simple care keeps your igniter running for years

-

Cleaning once a month: Open the combustion pot once a month. Remove ash from the surface of the ceramic ignition system with a soft brush. Do not use metal tools that damage ceramics. This simple procedure extends the life of the ignition device.

-

Twice a year inspection: Multi-meter confirmation of resistance between ignition terminals (at power off). It should read 30-60 ohms when cold. Numbers far outside this range mean your igniter is wearing out.

-

Check ignition time: Biomass stoves and boilers should be ignited within 3-5 minutes. If ignition takes some time, check the air flow first. Most slow-start problems come from blocked air vents, not bad igniters.

-

Replacement: Check the ceramic ignition device when cleaning. Small cracks mean it’s near the end of life. Replace cracked units before complete failure to prevent emergency service calls.

Domande frequenti

How long does a ceramic ignition system last?

3-5 years for home use and 2-4 years for business use are common. This is equivalent to 30,000 to 100,000 ignition cycles. Actual life depends on the system’s startup frequency and maintenance status.

Can I replace metal with ceramic?

It is possible if the voltage and size match. Ceramic ignition devices usually fit the same mounting position as conventional metals. A simple adapter bracket may be required. Check with your supplier for compatibility with your biomass stove model.

Does the ceramic ignition system operate with wet or low-quality fuel?

Ceramic materials handle various fuel qualities better than traditional materials. However, very wet fuel (over 25% moisture) is difficult to ignite any ignition device. Use fuel with 6-12% moisture content for optimal results. Store biomass pellets and chips in a dry place.

Final Advice

Ceramic igniter will help your biomass stove or boiler run smoother and longer. It uses less power and stays reliable over time. Although it may be a little more expensive in the short term, you will be saving money on replacement and repairs. Select a reliable ceramic manufacturer with ISO certification. Contact us today to know more and get the right ceramic igniter for your system.