A procurement manager shared the costly lesson. His team purchased semi insulating sic substrates based on price only. They ignored the specifications of ceramic materials. Six months later, a device failure caused a loss of $2 million. This guide helps you procure appropriate insulated substrate materials. You can avoid expensive mistakes.

1. Advanced SiC Ceramic Materials Overview

1.1 Ceramic Substrate Properties

carbure de silicium is the best ceramic technology for electronics. Semi-insulating SiC combines high thermal conductivity with electrical insulation. These ceramic substrates operate at temperatures up to 1,700°C and maintain strength even at extreme temperatures.

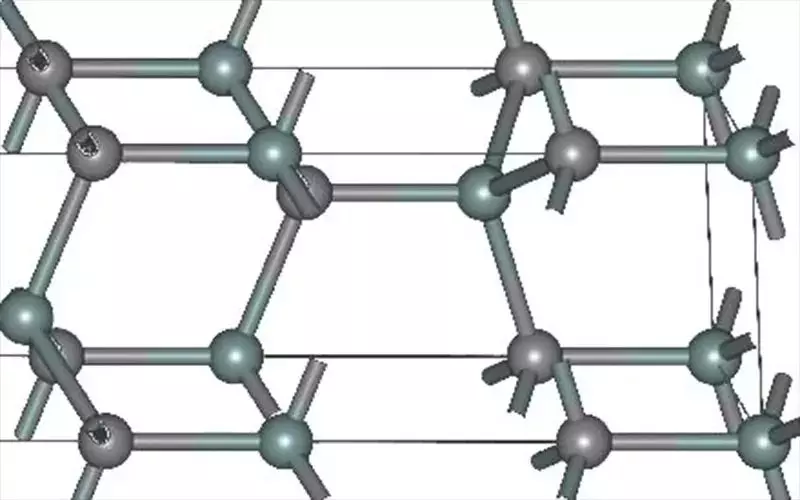

Fig 1: Silicon carbide crystal structure and properties

Source: Adapted from materials science literature

The ceramic structure controls performance. The resistivity of semi insulating sic ceramic is 10^6-10^12 Ω·cm. This is achieved by a controlled crystal defect. N-type ceramic substrates use nitrogen doping. This creates a conductive path with resistance of 0.01-1 Ω/cm.

1.2 Manufacturing Excellence in Ceramic Processing

Precision technology is required for advanced ceramic manufacturing. By the Physical Vapor Transport (PVT), the base material ceramic is formed at more than 2,000°C. Insulating substrate ceramics need extra purification steps. This increases costs by 300-400% compared to conductive types.

High-quality ceramic manufacturers control the crystal orientation. They manage surface finish and defect density. Top suppliers attain a micropipe density of less than 1/cm² and maintain a surface roughness of less than 0.5 nm RMS.

Fig 2: SiC ceramic substrate manufacturing process flow

Source: Industrial ceramic processing documentation

SiC Ceramic Substrate Specifications

|

Propriété |

Semi-Insulating SiC |

N-Type SiC |

|

Resistivity (Ω.cm) |

10^6 - 10^12 |

0.01 - 1 |

|

Conductivité thermique |

3.7 W/cm⋅K |

3.7 W/cm⋅K |

|

Maximum heat resistance temperature |

1,700°C |

1,600°C |

|

Ceramic Hardness |

28-35 GPa |

28-35 GPa |

|

Cost of procurement |

3-5 times of standard |

Base Value |

2. HPSI vs Vanadium-Doped Ceramic Substrates

2.1 High-Purity Semi-Insulating (HPSI) Ceramics

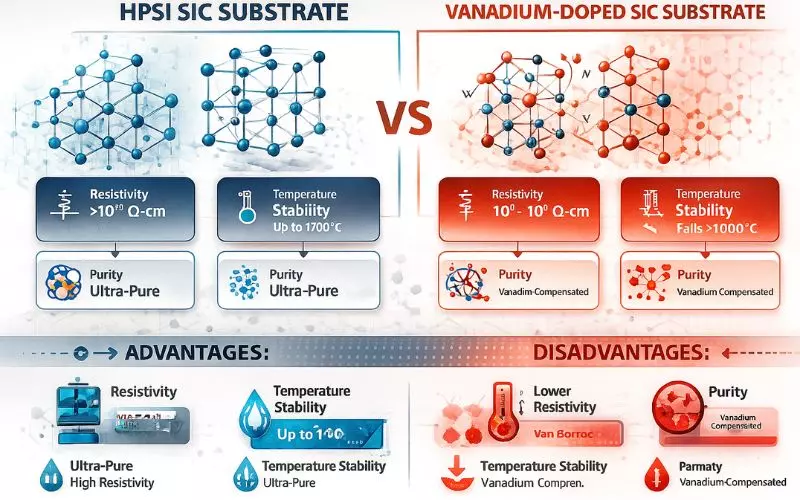

HPSI ceramic substrates are high quality semi-insulating SiC materials. These ceramics are insulated by crystal defects. No metal dope agent is used. Carbon pores form a deep energy level that effectively traps the charge carrier.

One communication device manufacturer switched to HPSI ceramics. Vanadium additives caused temperature failure. The HPSI board operates up to 1,700°C. V-doped ceramics become conductive above 1,000°C.

Fig 3: HPSI vs Vanadium-doped SiC substrate comparison

Source: Semiconductor substrate analysis studies

2.2 Vanadium-Doped Ceramic Limitations

The initial cost of vanadium-added insulated substrate ceramics is low. But there is an operational problem. When the device is miniaturized, the backgate effect occurs, causing unexpected conductivity. It also deteriorates at high temperatures.

V-additive ceramics are effective for specific applications. The operating temperature must be below 800°C. Cost optimization influences material selection. Multiple suppliers offer low-cost ceramic options.

3. Ceramic Substrate Applications in Power Electronics

3.1 Power Device Integration

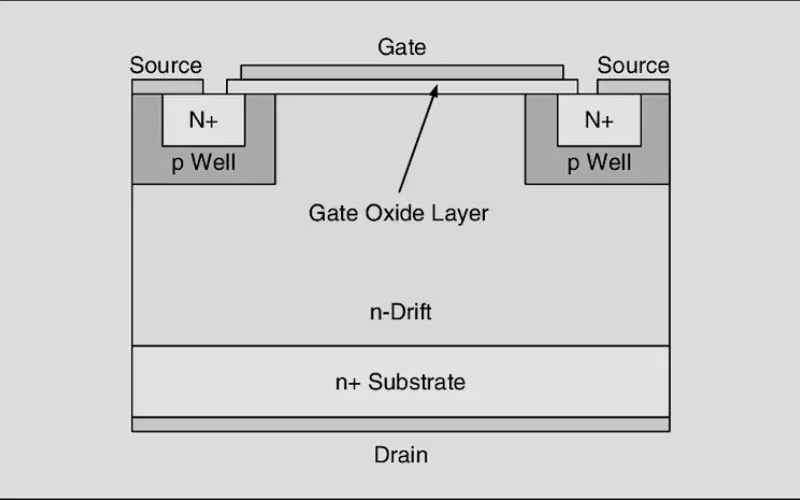

In modern électronique de puissance ceramic substrates are used for thermal management. Silicon carbide ceramics achieve high power density. This is not comparable to conventional materials. One EV manufacturer reported a 40% increase in efficiency. The company uses N-type ceramic substrates for inverters.

Fig 4: Power electronics using SiC ceramic substrates

Source: Power device application examples

Selecting ceramic substrates affects system design. Low-resistance N ceramic reduces loss of MOSFET and IGBT. Thermal conductivity eliminates hot spots, thereby preventing device reliability problems in automotive applications.

3.2 High-Temperature Ceramic Performance

Advanced ceramic substrates function in harsh environments. Military contractors use semi insulating sic ceramics for radar applications. These systems operate in desert thermal environments above 70°C. The ceramic matrix maintains electrical insulation and dissipates heat from sensitive GaN devices.

Industrial motor drives benefit from the thermal stability of ceramics. Pump manufacturers reduced their warranty claims by 60% by switching from alumina to silicon carbide ceramics.

4. RF and Microwave Ceramic Applications

4.1 GaN-on-SiC Ceramic Technology

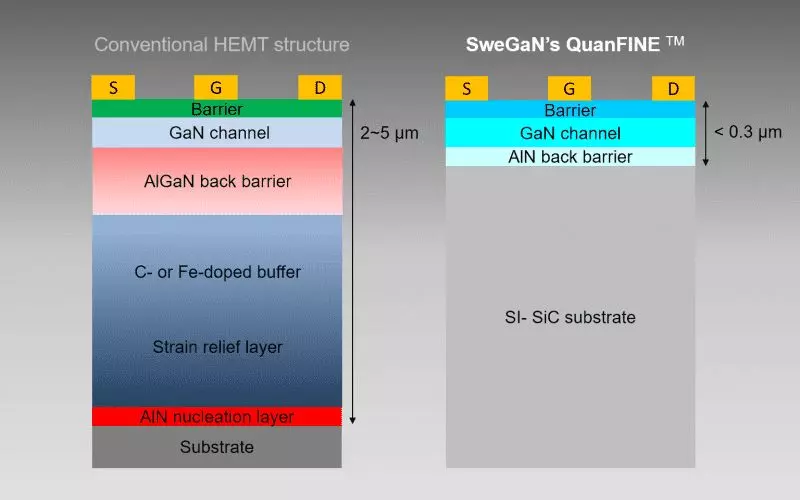

When you are dealing with the challenging RF applications, you mix the gallium nitride with the insulating substrate ceramics. This solution provides the best 5G infrastructure and satellite communications performance. The SiC ceramic allows thermal control as you continue to have electrical isolation of clean signals.

Fig 5: GaN-on-SiC RF power amplifier structure showing substrate integration

Source: RF device architecture documentation

Ceramic properties directly impact your RF performance. Low dielectric loss and high thermal conductivity is required so that power amplifiers can be built at millimeter-wave frequencies. These ceramics are provided by defense contractors when you construct radar systems.

4.2 Ceramic Manufacturing for RF Applications

When you order RF ceramic substrates, then you require specially manufactured operation at high frequencies. Mirror finishes that are produced by chemical mechanical polishing have a sub-nanometer RMS. Semi insulating sic wafers are subjected to several tests in order to make sure that you end up with uniform dielectric properties.

The major suppliers invest in RF performance metrology equipment. When you measure quality, vector network analyzers ensure that there is dielectric uniformity across the wafers.

5. Industrial Sourcing and Procurement Strategies

5.1 Ceramic Supplier Evaluation Framework

The purchase of ceramic substrates needs thorough supplier evaluation. The ISO 9001 certification gives minimum quality assurance. More complex ceramic uses require further certifications such as AS9100 of aerospace components.

Premium ceramic suppliers have technical support capabilities that commodity vendors do not have. Application engineers, who are aware of the ceramic properties, as well as the problems of integrating the device, are invaluable in the development of the new product.

5.2 Global Ceramic Supply Chain Management

There are complicated global supply chains in insulating substrate ceramic procurement. Major suppliers have facilities in various locations to guarantee supply chain. The sourcing decision of ceramic materials is increasingly becoming geopolitical.

Quality requirements, delivery time and support should be discussed during contract negotiations. Long-term contracts offer good prices and also they guarantee priority when there is a shortage.

6. Ceramic Substrate Quality Standards and Testing

6.1 Industry Standards Compliance

Insulation sic code varies according to application and region. ASTM F1241 sets up basic requirements of silicon carbide ceramic substrates. SEMI standards specify requirements of geometry and surface quality of wafer. Regulatory compliance is guaranteed by following the proper insulation sic code.

The standards of military uses are stricter. The specifications of MIL-PRF guarantee the dependability of the material under severe conditions. Different performance criteria that you should take into account are covered by each insulation sic code specification.

6.2 Quality Control and Incoming Inspection

In-depth inspection at the inlet prevents flaws, which may affect the production outputs. X-ray topography is used to see crystal defects that cannot be seen by optical means. The measurements are performed using Hall effect to check the resistivity in the wafers.

Intelligent buying teams create supplier scorecards to monitor quality indicators. Frequent inspection of suppliers will ascertain that there is no further violation of insulation sic code standards.

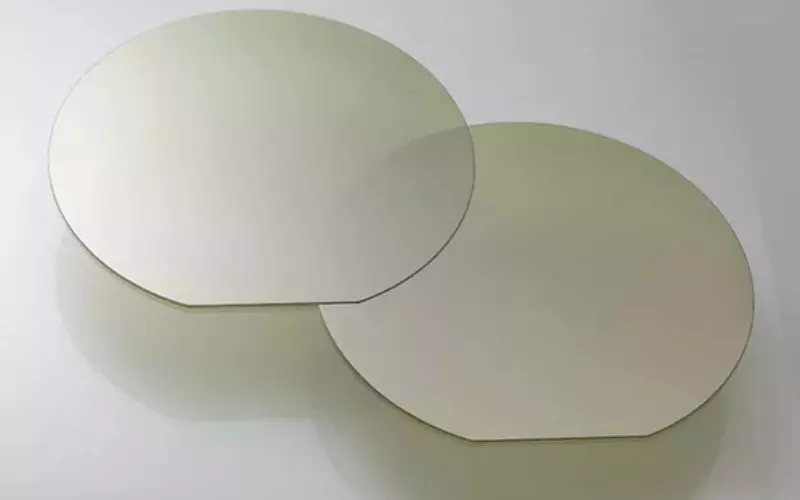

Fig 6: High-quality SiC ceramic substrates for industrial applications

7. Cost Analysis and Budget Planning for Ceramic Materials

7.1 Total Cost of Ownership Modeling

Semi insulating sic ceramics are initially more expensive and are better and longer lasting. In 18 months, one power company saved money. They were less problematic as far as warranty was concerned and were more efficient. Sophisticated customers consider the overall expenses, rather than the retail price.

The more ceramics you purchase the more you save. Annual contracts with minimum quantities attract 15-20 per cent discounts as opposed to small purchases. There are other companies that save even more when they purchase in bulk. Before committing to a lot of things, check your technology plans to avoid wastage.

Look at the long-term effects in comparison. Nicer ceramic substrates will save you money in maintenance and also enhance the performance of your product.

7.2 Market Dynamics and Pricing Trends

The supply of silicon carbide ceramics remains low. Electric vehicles and renewable energy is increasing demand. The major suppliers increase production and shipment takes more than 20 weeks to deliver high-grade products.

Bigger wafer sizes are more expensive per unit but provide value in the high volume production. Ceramic substrates of six and eight inches are more efficient in large orders. Intelligent buyers get space in advance to prevent congestion.

8. Supplier Landscape and Vendor Selection

8.1 Premium Ceramic Substrate Manufacturers

The best suppliers are the ones who have decades of experience in silicon carbide. Their high production assists you in receiving consistency on quality and reliability in the delivery of large orders. Technical support involves application support and failure analysis.

Other suppliers apply sophisticated crystal growth technology. They produce superior ceramic materials that are used in hard tasks. Their research-grade and specialty substrate is targeted at new technology markets. Tailor-made specifications suit the needs.

8.2 Regional Supplier Considerations

The price of Asian suppliers of ceramics is competitive in terms of standard specifications, but technical support differs. The quality requires close checks with suppliers. During peak times, the lead times increase.

The suppliers of European ceramics are low-cost conscious but are more concerned with quality and technical service. They collaborate with automobile and industrial businesses. Insulation of substrate ceramics provided by these vendors is usually subjected to very stringent quality requirements.

9. Decision-making Framework for Selecting Ceramic Materials

Intelligent customers have definite decisions when selecting ceramic substrates. Your application requires material requirements. Vendor choice is influenced by budget restrictions. Technology plans assist you in controlling the inventory and suppliers.

Risk checks are checks on stability in supply chains, technological changes and competition. Big supply risks could be achieved by using one supplier, but could be more successful. The two suppliers are employed by many companies to minimize risks at the cost of additional qualification expenditures.

Consider the specifications of ceramic substrates according to the requirements of the entire system. Semi insulating sic ceramics is the best to use in RF applications where electrical isolation is required. Types in the N-type are more appropriate in power electronics where the most important factor is electrical flow. There are trade-offs in each application that determine the best material to use.

Questions fréquemment posées

1. What quality standards should be specified in ceramic substrate procurement?

Based on ASTM F1241 compliance, additional criteria should be set according to application requirements. MIL-PRF certification is required in the military and aerospace field.

2. How to evaluate the technical capabilities of ceramic board suppliers?

When selecting vendors, in addition to basic material specifications, application engineering support, failure analysis capability and customization options should be evaluated.

3. What is the best procurement strategy for ceramic materials?

Long-term contracts with quantity guarantees should be utilized to obtain price preferential treatment and supply stability. In risk management, ensure multiple suppliers for critical applications.

Conclusion

Advanced ceramic board procurement balances performance, cost and supply chain needs. semi insulating sic ceramics offer excellent performance in demanding applications. N-type variants optimize cost efficiency. For professional guidance on advanced ceramic solutions, contact MAGNIFIQUE which provides you comprehensive technical consulting and custom manufacturing services.