Giới thiệu

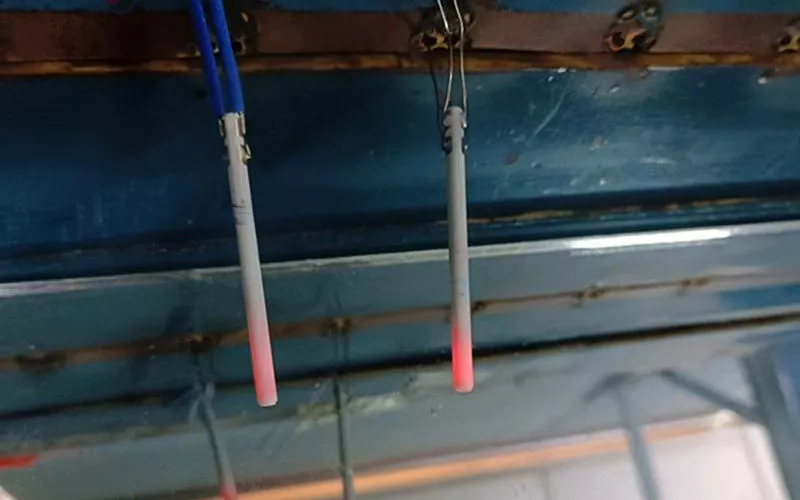

Diagram 1: High-power ceramic heating element

High-power ceramic heating elements are at the forefront of modern heating technology. Primarily because they possess the necessary features to excel in high-temperature environments. Now we’ll explore some of those key features and how you can utilize them in several applications.

Characteristics of High-Power Ceramic Heaters

A high-power ceramic heating element is a solid heating device produced from vật liệu gốm tiên tiến. Materials that can easily withstand high temperatures without melting or breaking down.

Diagram 2: Ceramic materials

The resistance wire is the major component of this rugged ceramic heater. It’s either composed of Nichrome or any other suitable alloy based on the engineer’s preference. This wire is wrapped around the ceramic body (alumina).

Diagram 3: Resistance wire

When you pass electricity through the resistive material, this is what happens immediately: the ceramic first absorbs and then distributes the heat evenly across its surface. This way, you get a powerful heat source.

The ceramic element heater helps to spread the heat uniformly. That way, you can avoid overheating in a particular spot. This might look harmless, but it’s vital in complex applications like soldering a capacitor or wires.

High-power ceramic heating elements are a stronger grade of ceramic heating elements. Truth is, they have been designed to work better in environments where normal heaters would burn out quickly. You will see them in applications like heavy-duty dryers, furnaces, industrial ovens/kilns, 3D printers, laboratory equipment, etc.

One way they achieve this is by generating larger amounts of heat than other heaters while maintaining stability under intense circumstances.

Today, many high-power ceramic heaters come in various shapes like rods, cartridges, tubes, plates or honeycomb blocks. It now depends on where you want it installed.

The fun fact is that ceramic heater elements can last you longer than virtually any other type of heater. This again is due to their impressive strength and resisting power. They’ll keep a maximum performance with very little maintenance.

Some of the properties of a high-power ceramic heater are:

-

Maximum operating temperature: 1000 - 1700°C (depending on the type of ceramic material used).

-

Thermal conductivity: 20 - 30 W/m·K

-

Tensile strength: 80 - 200 MPa.

-

Compressive strength: 2000 - 2500 MPa.

-

Electrical resistivity: 10⁸ - 10¹⁴ Ω·cm

-

Thermal expansion coefficient: 7-9 × 10⁻⁶ /°C.

-

Dielectric strength: 10 - 15 kV/mm

-

Heat capacity: 700 - 900 J/kg·K

-

Density: 3.6 - 3.9 g/cm³

-

Thermal shock resistance: Withstands 200 - 300°C sudden temperature change without cracking.

-

Flexural Strength: 100 - 50 MPa

-

Melting Point of the ceramic material: 2000 - 2050°C (for alumina-based ceramics)

-

Porosity: Usually less than 1% (high-density, low-porosity structure).

-

Surface Hardness: 1500 - 2000 HV (Vickers Hardness).

Key Features of High-power Ceramic Heating Elements

High-power ceramic heating elements have many interesting features you can explore. These key features will make you choose them over and over again.

-

Fast Heating:

It doesn’t take long to reach very high temperatures. They literally heat up within a few seconds. So, they’re your best bet for heating systems that need quick heating.

-

Độ ổn định nhiệt tuyệt vời

Ceramic heater elements are designed to withstand thermal shocks. This means you’re guaranteed smooth operations without sudden temperature fluctuations.

-

High Heat Resistance

These ceramic heater elements can also function well in extremely high temperatures. So, you have no reason to worry while using it in such conditions.

-

Even Heat Distribution

Their excellent design expels any concern about uniform heat distribution. These high-power ceramic heaters are excellent heat dissipators. Meaning, they’ve got you covered.

-

High Strength and Resistance to Unfavorable Conditions

They are strong and able to resist cracking or rusting. You can trust them even in highly demanding industrial conditions.

-

Energy-saving Capacity

Ceramic materials are popular for their high heat storage. It therefore means their energy-saving capacity is impressive. This important feature can, in turn, help you save costs and increase productivity.

-

Sự an toàn

They have insulators that help maintain a well-controlled surface temperature during operation. Thereby minimizes the risk of overheating and electrical shock.

-

Độ bền

Long lifespan is also a key feature of any high-power ceramic heating element you purchase. They boast this ability because of their high thermal conductivity and shock resistance.

How Does a High-Power Ceramic Heating Element Work?

High-power ceramic heating elements perform in a clear process - they quickly convert electricity to heat energy and spread it evenly across surfaces.

How? To begin with, electricity is passed through a specially designed ceramic material (alumina) or an insulator material. Then, heat is generated immediately by the material’s resistance to electricity.

This heat generated is controlled and steady in whatever system you want it to power. Why? Ceramics excel at handling extreme temperatures without breaking down.

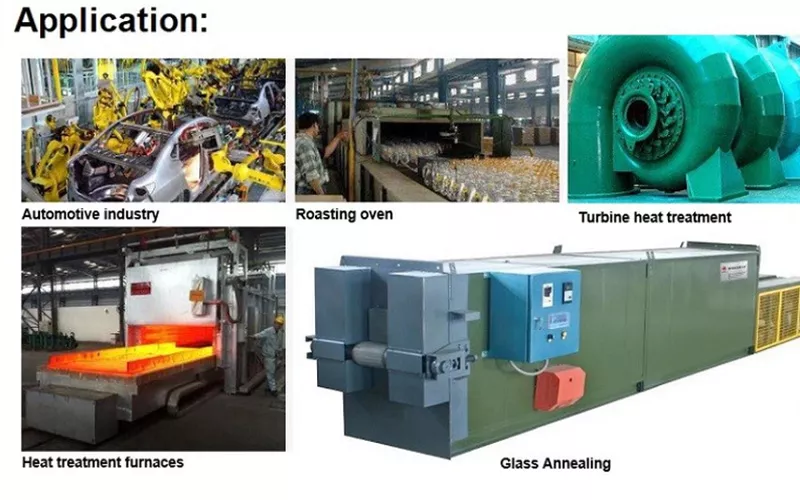

Ứng dụng của bộ phận gia nhiệt bằng gốm

Diagram 4: Different application of ceramic heater

There are many applications that require a high-power ceramic heater. Aside from high-temperature environments, you may also need them in a wide range of applications, like:

Industrial Furnaces and Kilns

High-power ceramic heaters are built to provide your industrial systems with intense and steady heat. This heat is very much needed in heavy machine/metal works and glass processing.

Thiết bị y tế

Medical procedures that require sterilization, safety and incubation can be made faster with ceramic heater elements. Their high power ensures accurate temperature control and reliability.

Điện tử

High-power ceramic heating elements heat up quickly and do not wear out easily. Which means you can use them for any delicate electronic work that demands accuracy and speed.

Space Heaters

Ceramic heaters can help warm up rooms, offices, warehouses, etc. In fact, most space heating systems today use high-power ceramic heating elements.

Drying and Dehydration Systems

They are a safer and more reliable option in food dehydration or industrial drying lines. This is because they consistently produce even and controlled heat that prevents burning.

Advantages of Ceramic Heating Elements

High-power bộ phận gia nhiệt bằng gốm are a far better choice compared to metal heaters. Some of the many advantages you’ll enjoy while using them in several applications are:

-

These ceramic heater elements can withstand extreme temperatures without breaking down like metal heaters.

-

You are guaranteed a very fast and steady heat while using them. This is because of their high thermal conductivity.

-

You will enjoy high productivity, save more energy and cost while using ceramic heater elements. Want to know why? It’s because they have an inbuilt system that stores heat longer.

-

Under unfavorable working conditions, they will offer you a better performance compared to other heaters. Simply because they are specifically built to survive dust, chemicals and corrosion.

-

They have excellent temperature control compared to other types of heaters. This means you can rely on them to work well in high-power industrial lines. A good example is the PTC (Positive Temperature Coefficient) heating element.

-

They can help you manage large systems and compact devices excellently. This is due to their excellent heat dissipation.

-

High-power ceramic heaters have high strength and a longer service life.

-

They only need a little maintenance compared to metal heaters.

It’s obvious these advantages are not something you want to miss out on. So, if you’re yet to purchase yours, quickly contact us now at GGSGốm sứ for top-quality ceramic heaters.

Những câu hỏi thường gặp

How do high-power ceramic heating elements handle sudden temperature changes without cracking?

It’s due to the advanced ceramic materials they are produced from (e.g. Alumina). For instance, Alumina has high thermal shock resistance that allows it to withstand rapid heating and cooling cycles that would destroy many other heater elements.

Can ceramic heaters operate safely in dusty or moist environments?

Yes, because they have chemically inert sealed ceramic bodies. This helps to protect their internal components from dust, moisture or corrosion.

Why do ceramic heating elements last longer than metal coil heaters, especially in high-temperature applications?

High-temperature applications require heating elements that are stable enough to resist extreme heat, oxidation and thermal shock. Ceramic heater elements do this way better than metals, and as a result, last longer.

How can I know if a high-power ceramic heating element is the right choice for my equipment?

Depending on your preferences or the type of equipment you use. For example, it’s the right choice if you want your system to heat up faster under very high temperatures.

Phần kết luận

Ceramic heating elements have proven to be the most reliable heaters. You obviously don’t want to overlook the impressive features and high-power efficiency they offer in various heating applications. Key features like precise temperature control, strength and durability make them so popular in household and industrial settings. They’re the ultimate frontrunners in modern heating!