SiC Wafers / SiC Substrates

GORGEOUS is a leading international ceramic supplier, specializing in providing customers with SIC substrates/wafer products used in new energy electric vehicles and semiconductor manufacturing. We can customize exclusive solutions based on the application!

Silicon Carbide Substrate Solutions

- Multi-Specification Wafer Supply: We offer standard wafer sizes, including 2-inch, 4-inch, and 6-inch, and can customize wafers based on customer needs.

- High-Purity Crystal Growth: We utilize advanced PVT (Physical Vapor Transport) and high-temperature sintering processes to ensure low defect density and high uniformity.

- Hassas İşleme: We offer wafer dicing, grinding, polishing, and epitaxial (Epi) growth processes to ensure surface quality and flatness.

- Metallization and Post-Processing: We offer coating, ion implantation, patterning, and etching services tailored to customer needs to enhance device integration.

- Strict Testing: We conduct defect inspection, thickness uniformity testing, and surface roughness testing on every wafer to ensure it meets the diverse needs of our customers’ high-end applications.

Leading International SiC Substrate Supplier

GORGEOUS has over 15 years of expertise in high-performance ceramic substrate manufacturing, dedicated to providing customers with high-quality SiC substrates and wafers.

We utilize advanced crystal growth technology, employing high-temperature PVT, to produce large-scale, low-defect SiC crystals to meet global market demands.

We offer a complete processing chain, from crystal growth → wafer slicing → polishing → epitaxy → metallization, providing customers with a one-stop solution and ensuring consistent quality.

Our products are marketed globally and have earned the trust of numerous international customers. Whether you’re in the new energy vehicle, renewable energy, communications, or high-end semiconductor industries, GORGEOUS can meet your needs!

When you choose GORGEOUS, you’re not just choosing a supplier; you’re choosing a trusted manufacturing partner capable of large-scale production and fast delivery.

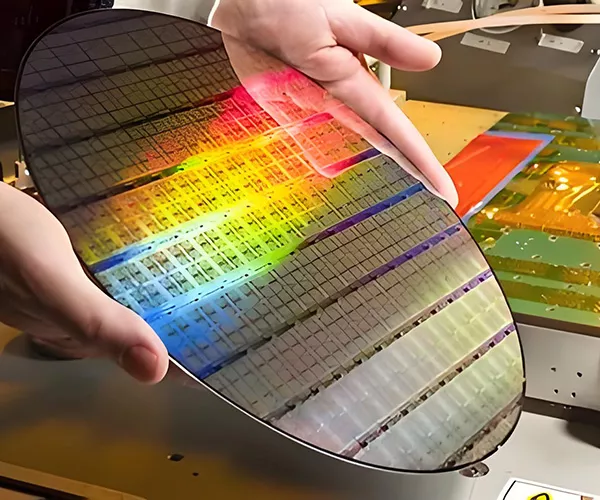

Silicon Carbide Substrate/Silicon Carbide Wafer Product Gallery

4H n-Type SiC Substrate

| Polytype | 4H |

| Diameter(mm) | 150/200 |

| Orientation(°) | 4 |

| Thickness(μm) | 350/500 |

| Yüzey Kaplama | Epi-ready |

4H Semi-Insulating

| Polytype | 4H |

| Diameter(mm) | 100 & 150 |

| Orientation(°) | 0 |

| Thickness(μm) | 500 |

| Yüzey Kaplama | Epi-ready |

Y

Silicon Carbide Substrate/Wafer Applications

Electronics and Semiconductor Fields

Alumina substrates offer excellent electrical insulation and heat dissipation properties, and can be used in printed circuit boards (PCBs) and hybrid integrated circuits (HICs).

Common applications for these substrates in the electronics and semiconductor fields include semiconductor packaging substrates, thick/thin film circuit substrates, and sensor carriers.

Communications and RF Fields

Alumina substrates can be used in the communications and RF fields as RF circuit substrates and microwave device substrates. They maintain low dielectric loss and stable signals in high-frequency communications (such as 5G base stations and radar systems). As microwave device substrates, they are often used in devices such as filters, power amplifiers, and couplers to ensure high-frequency characteristics.

Automobile and New Energy

Alumina substrates can be used in automobiles and new energy vehicles as heat dissipation for power modules such as IGBT modules and motor drive modules, ensuring efficient and stable operation of the system. They can also be used as on-board electronic circuits.

Lighting and Display

Alumina substrates can be used in high-power LED lamp beads to dissipate heat, helping to avoid light decay; while in laser diodes and displays, ceramic substrates can provide good electrical insulation and thermal management.

Aerospace and Military

Radar and satellite electronic devices require high-frequency, high-power, and highly reliable components, and alumina substrates can provide high insulation and thermal stability.

Minimum Sipariş Miktarı Konusunda Endişeleniyor Musunuz?

Our SiC substrates offer custom monolithic manufacturing to meet small order needs. Experience our services today.

Neden GORGEOUS'u Seçmelisiniz?

At GORGEOUS, quality control is our top priority. Every SiC substrate is manufactured to our customers’ exacting specifications and undergoes multiple inspections and tests, from raw materials to finished product, to ensure consistent performance and reliable quality.

Our factory is certified to IATF 16949:2016 for the automotive industry and ISO 9001:2015 for international quality management systems. This not only demonstrates our commitment to quality, but also ensures we can provide our customers with high-standard customized solutions.

Geçiş Başarılarımız Referanslar

The wafers provided by GORGEOUS are of stable quality, delivered on time and have excellent performance.

Christopher Johnson

We needed custom silicon nitride substrates for high-power electronic modules, and GORGEOUS fully met our technical requirements.

Richard Collins

The silicon nitride ceramic substrates provided by GORGEOUS have high surface finish, uniform microstructure and good performance consistency.

Lukas Meier

SSS

What is the heat dissipation performance of silicon carbide substrates?

SiC substrates typically have a thermal conductivity over three times that of silicon and can effectively reduce device operating temperatures. In high-power applications such as new energy vehicles and photovoltaic inverters, the use of SiC substrates enables long-term stable operation at high temperatures and high currents, effectively extending system life.

Is your delivery time stable?

Silicon carbide crystals are difficult to grow and process, which generally results in higher costs than silicon substrates. However, GORGEOUS’s production technology is highly mature, and we have a comprehensive production line and stable supply capabilities, supporting small-batch R&D to large-scale mass production, while ensuring stable delivery to customers.

Why is defect density in SiC substrates important?

Defect density (such as micropipes and dislocations) directly impacts chip yield and performance. Low-defect-density SiC wafers significantly improve device consistency and reliability, making them a key concern for customers during procurement.