For your high-precision laboratory process, crucibles greatly determine your results accuracy. A crucible made from PBN material provides the exceptional strength, purity, accuracy, and consistency that your industry demands. Whether for manufacturing semiconductors, conducting material research, high-temperature reactions, or quantitative analysis, a PBN crucible delivers outstanding stability and cleanliness. This guide explores how selecting PBN crucibles in your laboratory improves product quality, process performance, and cost savings.

Understanding PBN Material Used in Your Crucible

-

PBN material is a synthetic керамика called Pyrolytic Boron Nitride that’s created through a high-temperature chemical vapor deposition process. This process doesn’t use sintering agents or binders, which ensures your PBN material is over 99.9% pure.

-

A PBN crucible is a vessel made from the PBN material. It utilizes the material’s purity to deliver results in your high-tech applications or extreme conditions. Your laboratory may also utilize PBN-coated graphite products, which offer chemical inertness, thermal stability, and temperature resilience at less weight.

-

In your lab, PBN crucibles are used for tasks that demand very little contamination. They include determining ash content, high-temperature experiments, material testing, and evaporating metal fumes.

Properties of PBN Crucibles Used in Your Laboratory

Химическая инертность

-

Your PBN crucible resists corrosion from alkalis, acids, molten metals, organic reagents, and salt. This chemical inertness helps prevent contamination in your industrial processing.

Excellent Purity

-

Your crucibles made from the PBN materials are manufactured through the CVD process and don’t contain metal contaminants, ensuring they retain a purity of 99.9% or higher. This further minimizes the contamination of your materials being processed.

High Thermal Stability

-

Your PBN Crucibles withstand up to 2,000 to 2,200 °C in inert conditions. This reduces failure and ensures safety in your high-temperature industry uses.

Механическая прочность

-

PBN has a dense hexagonal structure, which provides high tensile and flexural strength. This ensures your crucibles resist cracking and last longer.

Low Thermal Expansion

-

Your PBN material has a minimal thermal expansion coefficient. This property ensures your crucible maintains stability during cooling and heating.

Resistance to Thermal Shock

-

Your PBN crucible offers a high resistance to thermal shock, ensuring it doesn’t crack even under sudden changes in temperature.

“After switching to PBN crucibles, our process stability increased and contamination levels dropped to almost zero.”

— Chin Y., Lab Technician, ADV Materials Research Centre

Advantages of Using PBN Material For Your Lab Crucibles

-

PBN crucibles are durable and can serve thousands of cycles without degradation, wear, or tear. They also help minimize downtime in your industry as they require fewer replacements. This reduced long-term replacement frequency translates to cost savings, despite the upfront cost being higher.

-

Crucibles made from PBN material offer better process control as they allow your process to manage the temperature and heat conditions. They also offer enhanced purity, which ensures they don’t react with the materials you’re testing.

-

They also perform better in high-temperature applications due to their blend of good heat transfer, non-porous surfaces, and chemical resistance.

“PBN provided exceptional temperature resistance, also helped reduce downtime by up to 52%…”

— Robert M., Materials Engineer, KENelectricals Manufacturers

Applications of a PBN Crucible in Your Industry

Semiconductor Manufacturing in Your Industry

-

For your silicon or compound полупроводники, PBN crucibles are crucial for growing high-purity crystals. They help deposit thin films of your semiconductors on substrates during your epitaxy processes, and are also used to create thin material layers in your molecular beam epitaxy.

Manufacturing Your Medical equipment and devices

-

For your production of implants and biocompatible devices, a PBN crucible provides the required super-clean conditions. PBN is non-reactive, and so your crucible doesn’t interfere with your biomedical components.

Metal processing and metal evaporation in Your Industry

-

Your metal processing and evaporation demands high purity, chemical stability, and resistance to extreme temperatures. PBN crucibles deliver all these properties, ensuring minimal failures and contamination when melting your reactive Zirconium or Titanium metals.

Your High Temperature Laboratory reactions

-

During processes like crystal growth, your PBN crucible ensures safety and stability. PBN also withstands very high temperatures and is chemically inert, adding to its effectiveness in your reactions.

Material research

-

PBN crucibles are ideal for your materials testing laboratory, offering unmatched purity and inertness. This ensures that your process yields quality, unaltered results.

“We used PBN crucibles in our molten salt corrosion tests. Their structure remained the same, and contamination was very minimal”.

— Fang A., Research Engineer, Corrtests Labs

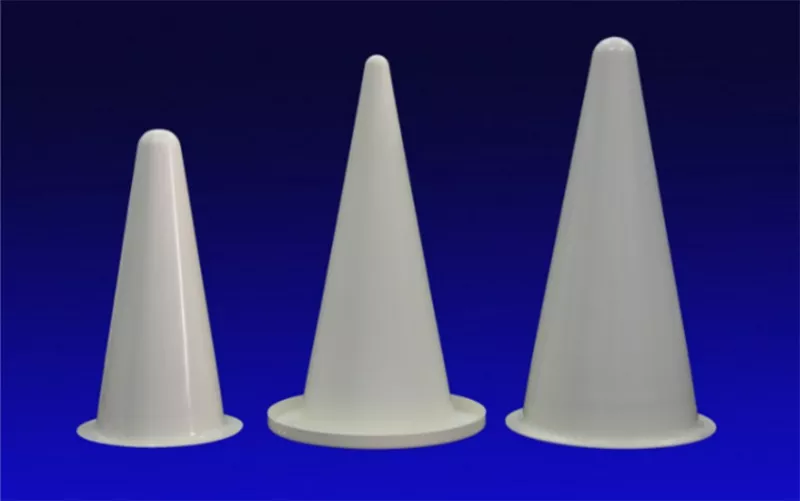

PBN Crucible Types and Where They Excel the Most

-

Cylindrical PBN crucibles: These offer uniform distribution of heat and are ideal for general laboratory uses, including your crystal growth processes. They do well in processing your semiconductors and high-purity reactions.

-

MBE crucibles: These are ideal for Molecular Beam Epitaxy when manufacturing your semiconductors. Your industry utilizes them during the growth of epitaxial layers.

-

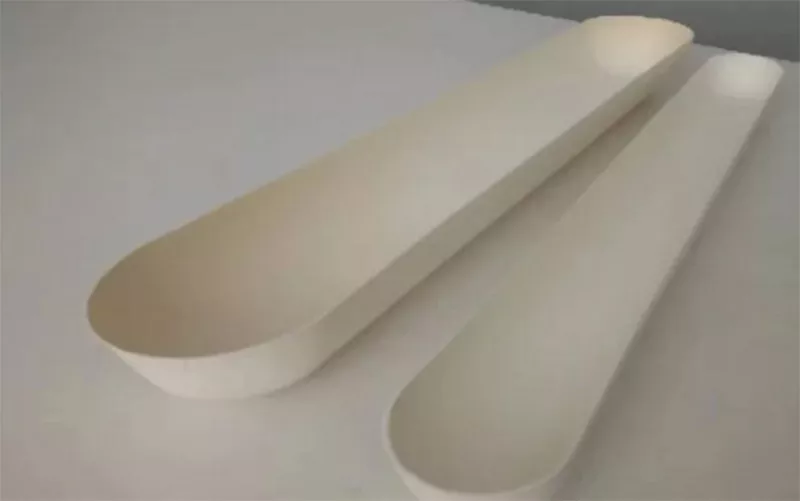

PBN Boat Crucibles: These ones are ideal for your Thin-Film Deposition, and in evaporating multiple materials. They ensure controlled flow of materials in your processes such as vacuum coating.

-

OLED PBN crucibles: These are used in testing and evaporating your organic compounds.

Using the right PCB crucible type in your laboratory process will enhance performance and results.

Crucibles made from PBN Material Vs other crucibles in Your Laboratory

|

Материал |

Температура |

Reaction With Chemicals |

Пористость |

Электроизоляция |

|

ПБН |

Up to 2000 °C or more |

Инертный |

Non-porous |

Отличный |

|

Up to 1473 K |

Умеренный |

Пористый |

Умеренный |

|

|

Высокий |

Реактивный |

Умеренный |

Conductive |

|

|

Varies |

Реактивный |

Низкий |

Conductive |

|

|

Up to 1600 °C |

Умеренный |

Пористый |

Хороший |

|

|

Up to 2000 °C |

Moderate to Low |

Пористый |

Хороший |

“Before adopting PBN, we tried Porcelain and Alumina. Their Chemical reactions and porosity brought significant errors…”

—Jackt C., Lead Chemist, Tempstar Labs

How to choose the right crucible For Performance in Your Laboratory Process

-

When selecting a PBN crucible, consider your process temperature, the material being heated, the level of purity needed. Ensure the crucible size, volume and heating profile aligns with your process needs

Where to Buy High-Quality PBN Crucibles For Your Laboratory Use

-

Purchase PBN crucibles from reliable suppliers like the Gorgeous Ceramic Group. We ensure consistent production quality, and offer a variety of PBN crucible types tailored to your industry demands.

“We have been sourcing PBN crucibles from Gorgeous for over two years. Their attention to detail and custom dimensions enhance our yield.”

—Jason O., Procurement Lead, GrowCrystal Laboratories

Conclusion and Your Takeaway

The quality of your crucibles impact your laboratory’s success. A PBN crucible offers your process outstanding purity, durability and thermal stability. Whether your industry process semiconductors or conducts materials research, PBN material is key to improving precision and productivity. Invest in the right crucible today, and your laboratory will benefit from the upgraded performance and long time cost-savings.

Contact Georgeous Ceramic today for more technical guidance or to explore specifications and customizations.

FAQs About PBN Crucibles

Q: What is a crucible used for in the laboratory?

A: Crucible is used to hold substances during your high temperature lab processes such as melting and evaporation.

Q: What is the function of the crucible in the laboratory when using PBN?

A: Crucibles made from PBN material retains your chemicals purity, resist thermal shock, and ensures your process lasts longer, hence providing reliable results.

Q: Why does a PBN crucible’s temperature performance stand out?

A: Your PBN crucibles withstand temperatures of up to 2000°C, or more when used in inert environments. They ensure high thermal stability and doesn’t crack easily, hence reducing downtimes in your lab.