Введение

Many modern industries consider aluminum oxide a very reliable and affordable option when making tools and abrasives due to its useful qualities. Little wonder that aluminum oxide is now a household name; it’s become so popular that you can find it virtually anywhere you look. So just in case, you’re among the many people wondering “what is aluminum oxide?” or why this ceramic material has so much popularity and widespread use, especially in tools? Then, wonder no more as today’s article will show you the properties of aluminum oxide that make it not only an easy but very beneficial option in tools and a wide variety of applications.

Что такое оксид алюминия?

Aluminum oxide, commonly known as alumina, is a whitish crystalline compound made from aluminum and oxygen. It is a very good electrical insulator as well as an amphoteric oxide ceramic material, meaning it can react with both acidic and basic mediums.

Aluminum oxide (Al2O3) is actually a basic advanced ceramic material known to be very hard and thermally stable. It’s one of the best ceramic materials you should consider when it comes to wear resistance. Industries in different sectors use it in a host of high-profile applications like cutting tools, grinding wheels, coatings of any kind, production of reliable abrasives, electrical insulator materials, feedthroughs, and even biocompatible medical implants.

Apart from being white and sometimes brown in color, you can produce Al2O3 by refining bauxite (a naturally occurring form of aluminum) using Bayer’s process.

Fun fact is, for a ceramic material with so many outstanding properties, alumina is relatively cheap and easy to find or produce, making it one of the best options for high-temperature applications and tool manufacturing. It can literally give you the same qualities that top advanced ceramic materials like silicon carbide or boron nitride will give, but at a lesser cost. Interesting right?

Now, let’s move on to see some of these properties of aluminum oxide.

What Are The Properties of Aluminum Oxide?

There are a lot of outstanding properties of aluminum oxide that make it a popular choice among manufacturers. They are:

-

It’s an efficient electrical insulator.

-

It is highly resistant to heat and extreme temperatures.

-

It has a high and stable thermal conductivity of about 30 Wm-1k-1

-

It is odorless and has a density of 3.987g/cm.

-

It has a high melting point of 3,762°F.

-

It has a high hardness of about 17GPa and a rating of 9 on the Mohs hardness scale.

-

Its molar mass is 101.960g/mol.

-

Its compressive strength ranges between 2500-4000 MPa.

-

It is chemically inert and insoluble in water.

-

It is highly resistant to corrosion, wear, and tears.

-

It is a suitable abrasive you can use anywhere.

-

It is lightweight and malleable.

Aluminum Oxide Uses

оксид алюминия use is found in almost any application because, aside from being an excellent ceramic material, it’s very affordable. In this section, we will x-ray some of the many uses of alumina.

Mechanics and automobiles

The mere fact that aluminium oxide has high strength, impressive wear resistance, thermal stability, and long-lasting power means it’s a very good mechanical material. It can help you produce automobile/machine parts, car doors/engine coatings, aircraft components, nozzles, refractory materials, kiln linings, thermocouple sheaths, pump impellers, spark plugs, feedthroughs, valves, strong pipes coated with Al2O3, etc

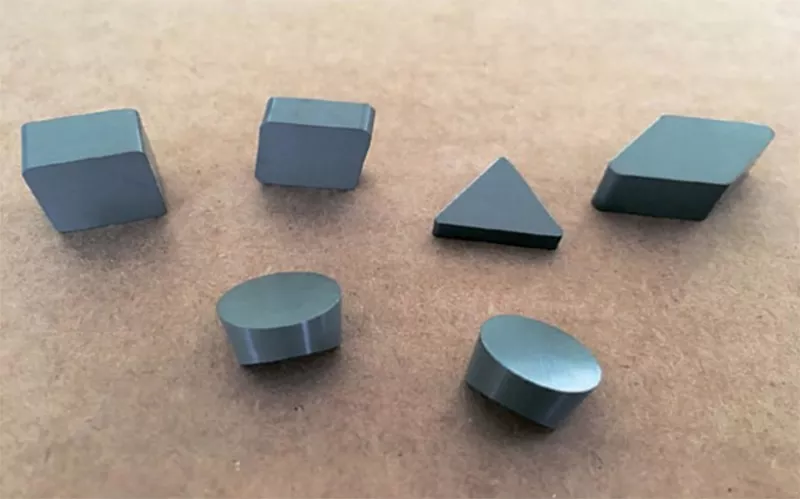

Ceramic cutting tools and equipment

If you want to produce efficient but low-cost cutting tools and equipment, then alumina ceramic material may be your best bet. Why? Its chemically inert nature makes it a perfect fit for plastic equipment, heavy utensils/household appliances, bricks, grinding wheels, furniture/design materials, machining tools, and tap washers.

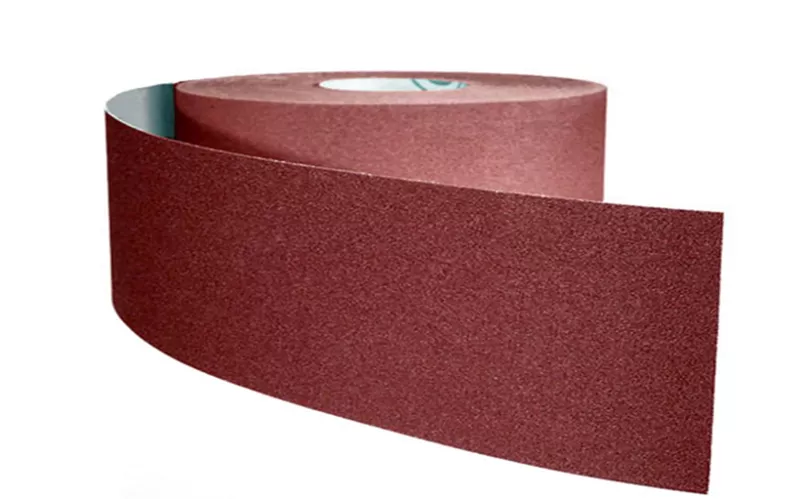

Абразивы

Apart from silicon carbide, there’s arguably no other better material to use in producing abrasives if not alumina ceramic material due to its high wear resistance. As a matter of fact, the commonly used aluminum oxide abrasive paper (sandpaper) helps engineers in woodwork and metalwork to not only polish but also put finishing touches to various materials like discs, belts, machine parts, etc.

t’s this same technique you can employ in terms of sandblasting using aluminum oxide blast media (in the form of wet/dry abrasive blasting) to shine surfaces or sometimes for paint stripping.

Электроника

Aluminum oxide uses in high-power electronics are multi-dimensional. You can utilize it in a range of applications, starting from heat-resistant and long-lasting coatings for your devices to efficient electrical insulators, heat sinks, and semiconductors for electronics, LED lighting systems, MOSFETs, computers, and many other high-temperature applications. As a new innovation, manufacturers now produce foaming agents in autoclaved aerated concrete (AAC) with aluminum oxide powder. Come to think of it, you can also get effective power lines, electric wires, and cables from aluminum oxide.

Лекарство

The wear resistance of aluminum oxide now benefits medicine thanks to advancements in technology. Medical implants used during surgeries can be coated on their surfaces with a biocompatible aluminum oxide form. Most enamels for dental beautification and surgeries also use aluminum oxide coatings.

Why is Aluminum Oxide Used in Tools?

So now that we’ve answered the question, “What is aluminum oxide, let’s look at why it is used in tools and so many other industrial sectors, because you know, as a manufacturer, choosing the right material and knowing when to use it is a very key part of the production process. In a case where there are so many other top-quality ceramic materials like SiC, B4C, why should you go for aluminum oxide instead?

Actually, the reasons are not far-fetched, considering the unique properties possessed by aluminium oxide.

First of all, aluminum oxide has tough compressive strength and durability. Now, imagine this quality in a tool; it’ll definitely be efficient and last you for a very long time. No surprise, most manufacturers don’t actually think twice before using it to make tools.

Also, aluminum oxide is a less expensive abrasive despite its properties. Unlike other abrasives, it’s suitable for so many casual and common applications. You really don’t have to break the bank if your application demands high hardness, thermal stability, wear, and temperature resistance. All you need to do is use alumina ceramic material, and you’ll get similar results to what an expensive керамический материал would give you.

Another exciting reason why aluminum oxide is used in tools is that it doesn’t rust or wear out easily. Now, this is something you should seriously consider because as tools and equipment become more integrated into our everyday lives, there is a need for them to comfortably withstand friction, frequent use, and strain.

With these, it’s obvious that aluminum oxide can easily serve as a durable and cost-effective ceramic material. So the choice is yours if you’re looking at producing or investing in aluminum oxide tools, abrasives, crucibles, insulators, and refractory materials.

The sheer size of the global alumina market, as shown by market estimates, is also a great testament to the effectiveness of alumina oxide ceramics in tools. As of 2024, the market was valued at an astonishing $12.5 billion, reaching a high of $80 billion in 2025 and projected to grow to over $90 billion by 2030. Currently, the compound annual growth rate (CAGR) is ranging between 7.5% to 7.8%, so now is the best time for you to invest and grab an early share of this trending market.

Часто задаваемые вопросы

Can humans be affected by aluminum oxide exposure?

Yes, but while aluminum oxide might not necessarily cause your body immediate damage, long-term exposure can be very harmful to your lungs, brain, and the nervous system. Leading to health complications like pulmonary fibrosis, pneumonia, dementia, seizures, bone fractures, etc.

What is the lifespan of aluminum oxide coatings?

Aluminum oxide coatings usually boast a long average lifespan of about 20-25 years, depending on how well you use them.

Does aluminum oxide have any substitutes?

Yes, a good substitute for alumina is sintered graft, also known as sintered bauxite or calcined aluminum oxide, usually made from the same material as aluminium oxide.

Заключение

Aluminum oxide (Al2O3) has proven to be a very useful advanced ceramic material to so many of these modern industries looking to cut costs and still produce high-quality tools. Not only does it provide you with excellent hardness, high wear resistance, and electrical insulation, but it’s also a very affordable option compared to the likes of Silicon Carbide and Boron Nitride. If you’re choosing aluminum oxide for your next project, contact us now at GGSКерамика to get some of the best alumina ceramics products. Don’t sleep on this opportunity!