Ever felt wondered when someone says Циркониевая керамика is the future of iPhone? The users of Apple iPhone must be aware about this recent advancement. Yes, iPhone is set to undertake this new transition for the good. Let’s explore how zirconia is marked to influence the future of iPhone design.

A quick Glance on Content

Is Zirconia a ceramic? Specialities of Zirconia

- Physical properties

- Механические свойства

- Electrical and Thermal Properties of Zirconia Oxide

- Химические свойства

- Shortcomings of current iPhone material spec

- Continuing innovation of Apple

- Does Zirconia fade over time?

Is zirconia a ceramic? Characteristics of zirconia

Why is Zirconia material being preferred over other ceramic in the manufacture of iPhone. Before we step into the topic lets study more on Zirconia , the material of choice.

Zirconia, ZrO2 is a technical ceramic existing in martensite form. This is one fundamental reason that makes it capable of absorbing good amount of stress. In general, Zirconia material is superior to common ceramics such as Alumina, ALN, Boron Carbide etc. Since its invention in 18th century, Zirconia has emerged as a key player in the technical ceramic industry.

Among all the advanced ceramic commercially available today, Zirconia is the one that offers highest fracture toughness. Zirconia Oxide also possesses extreme mechanical strength at room temperature. They are also corrosion resistant hence used in applications that require precision and performance.

Zirconia vs Aluminum oxide

One major key difference between Alumina and Zirconia is their composition itself. Alumina is composed of Оксид алюминия and Zirconia, Zirconium dioxide. Alumina is a stable oxide whereas Zirconia undergoes phase transition which makes it a choice in many applications. Some other key differences are given below.

- Alumina is harder than Zirconia in mohs scale which makes it suitable for applications susceptible to higher wear and tear. But Contrary, zirconia offers good toughness and fracture resistance.

- Zirconia has generally high melting temperature than Alumina which marks its suitability in high temperature application.

- Alumina function better as a heat conductor and electrical insulator when compared to Zirconia. As far as economic reasons are concerned, Alumina production cost is typically lesser to Zirconia.

Zirconia Ceramic properties

Now it’s time to navigate through a concise summary of the major properties of Zirconia oxide.

Physical properties

In its appearance Zirconia is whitish unless some additives are being used. It can also exhibit yellow and grey colours. The density of Zirconia material is around 5.7 to 6.1 g/cm3 which makes it one among the densest technical ceramic. Zirconia crystal structures are possibly three, such as tetragonal, monoclinic and cubic. Of which when engineering utility is considered tetragonal and Cubic Zirconia caters to more applications.

Often Zirconia needs to be stabilized using Yttria, ceria etc to limit its structural transformation under applied heat. Now Talking about interaction , Zirconia Oxide is mostly insoluble in water and acids and is inert in nature.

Механические свойства

Mechanical properties are often favoured over other properties to finalise the correct application. Zirconia and its various forms excel in its mechanical stability. For instance, Yttria stabilized Zirconia has a fracture toughness value of around 7 – 10 MPa0.5. Of course, there has emerged no technical ceramic that could surpass this value.

The flexural strength of Циркониевая керамика is Upto 1000 MPa. Now let’s talk about the Zirconia hardness scale. Zirconia hardness in terms of Vickers value is greater or equal to 11 GPa. This makes them ideal to function as cutting tools and abrasives.

Electrical and Thermal Properties of Zirconia Oxide

When it comes to thermal and electrical stability of Циркониевая керамика, It’s nothing less than impressive. Zirconia is an electrical insulator and Melting point of ZrO2 is at 2700degC.This shows its resilience and stability at higher temperature of operation. However, the thermal conductivity of Zirconia, ZrO2 is on lower side.

Теплопроводность циркония is around 2- 3 W/Mk. Zirconia functions well as thermal barrier coatings for applications involving engineering and aerospace. The thermal expansion coefficient is marked around 10 (10-6 / degC) for Zirconia.

Химические свойства

Corrosion resistance is another important property that gauges the suitability of a ceramic for applications that has material interactions. Zirconia, ZrO2 is generally inert. Hence when placed near other components, it doesn’t degrade. Zirconia is stable under oxidising environments Upto 1000 degC.

Apple using Zirconia Ceramics

Now coming to apple using Циркониевая керамика, Of course the above description of properties is self-explanatory. But to bring more clarity lets point out each property of importance. Some key reasons of interest that makes Zirconia preferred are strength and thermal conductivity aka heat dissipation. Others include good signal pass through and mechanical stability.

Shortcomings of the iPhone material spec

Since iphone5 introduction, Apple abandoned stainless steel material. It had shifted to anodised Aluminum that guaranteed a thinner version of the device. The final product was gorgeous, sleek, stylish and colour rich. But when taking the overall industry into consideration, with Alumina, Apple was no longer versatile.

Under current situation, Aluminum CNC is what is explored by apple. Of course, the integration of more process components inside the system again brought troubles. Since, Aluminum has already reached the threshold bending strength integration of more processors has resulted in compromised performances.

With the current material spec apple had issues of heat dissipation and material damage. This marked Apple’s need of a novel material, so as Zirconia to penetrate the market with uniqueness and good performance.

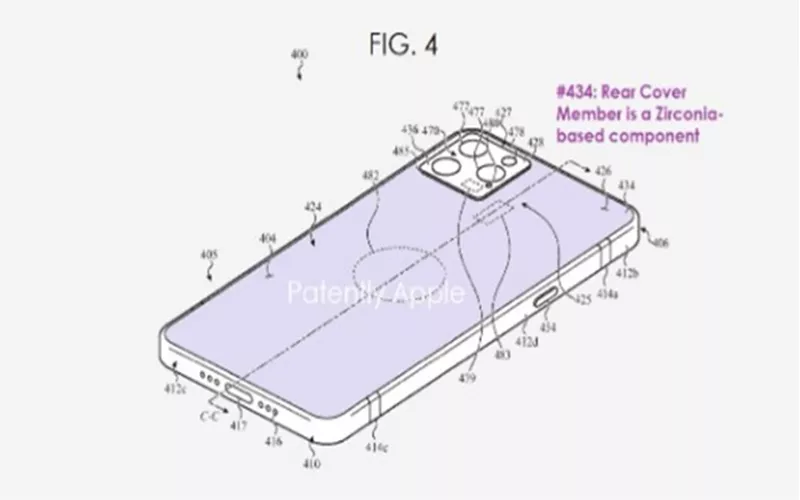

Continuing innovation of Apple

The usage of Zirconia, ZrO2 is going to benefit iPhone innumerably. It brings lot more advantages over the traditional material such as Aluminum. As an excellent material of choice, Zirconia ensures superior scratch resistance. It also guarantees good heat conduction, mechanical strength and signal pass through.

Of course, some may shoot the argument that with Zirconia material the production cost can turn higher. However, a realistic analysis shows the current iPhone 7 with Aluminum body has higher cost of production when compared to Zirconia material.

Does Zirconia fade over time?

As Цирконий marks its entry in iPhone and wearable apple devices, the surface finish is a concern to talk about. Does the material fade or wear over time needs to be overlooked. Now let’s see what’s Apple’s take on this matter.

Циркониевая керамика is going to offer a matte appearance to Apple devices. The company is exploring the textural configuration that makes it suitable to resist wear. On the other hand, the material must ensure an easy cleaning.

There is also huge probability that Apple may ditch its toughened glass like component over ceramic finish. However, this feature might be likely available in the top end or pro and pro max models of Apple. Of course, iPhone and ceramics are never strangers. iPhone 12 и iPhone 13 both come with Ceramic shield displays that offer 4 times drop resistance.

Итог

Использование Циркониевая керамика in Apple iPhone has several advantages over the conventional material of Alumina. In terms of signal strength, wear resistance, heat conduction and mechanical stability Zirconia material is superior. The introduction of Zirconia in iPhone also granted them a new overall outlook and unique market penetration.