If you are in the semiconductor business, you know that it is essential to find materials that perform under strict conditions. Aluminum nitride (AlN) heaters help manufacture better products with less defects. These special heaters manage high temperatures and ensure uniform heating throughout the chip. By using this heater, more chips can be produced in each production process.

Common Problems in Semiconductor Manufacturing

Before switching to aluminum nitride heaters, many manufacturers face significant challenges such as:

- Due to the lack of uniformity of temperature distribution, the wafer disposal rate has reached 25-30 percent.

- High energy costs: heating systems account for 40 percent. of the total production energy consumption.

- Frequent shutdown of equipment due to damage caused by thermal shock.

- Product quality instability is causing customer complaints.

- Precise temperature maintenance difficulties in advanced chip processes.

Traditional ceramic heaters cause these problems, but aluminum nitride heaters effectively solve them.

Why Aluminum Nitride Heaters Excel in Semiconductor Applications

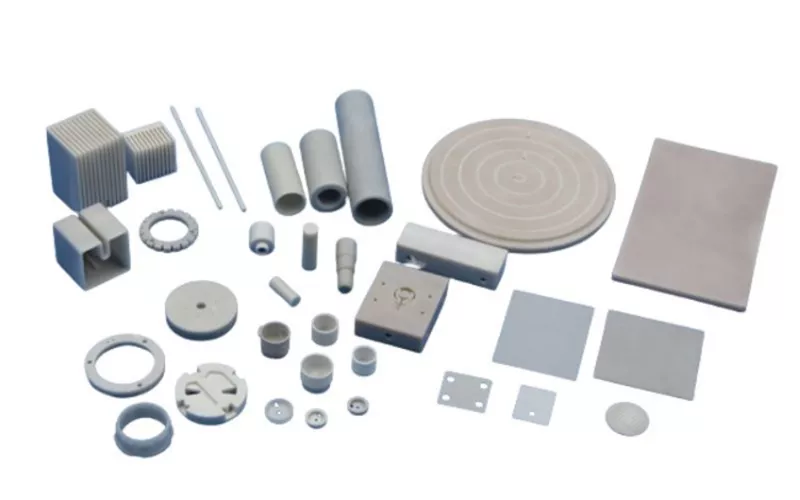

To achieve accuracy in a demanding environment, we need materials that can handle fast and complex processes. АlN stands out for its thermal conductivity, electrical insulation, and ability to withstand harsh conditions. Explore why this material is essential for полупроводниковые приложения.

Excellent thermal conductivity

AlN provides excellent thermal conductivity. Aluminum nitride heaters spread heat uniformly throughout the material, preventing hot and cold spots that damage the product. The thermal conductivity of the 140-220W/mK allows the heat to be transferred quickly and uniformly to the production material. Эти semiconductor heating solutions spread heat more evenly than alumina heaters, ensuring improved performance and safety.

Electrical Safety

Unlike many thermal conductive materials, AlN does not conduct electricity. This increases manufacturing safety when handling delicate electronic components. You don’t need to worry about electrical risks to your production line when using aluminum nitride heaters.

Understand quick temperature changes

When producing chips, it is often necessary to heat and cool the material rapidly. Many materials generate cracks under these conditions, but aluminum nitride heaters maintain strength even during quick temperature changes. Therefore, the process can be accelerated without damaging the wafer processing equipment.

Operating at ultra-high temperatures

AlN can be used without deterioration even in high temperature environments of 1,000 ° C. This allows for extremely hot processes that other semiconductor heating solutions cannot handle. Especially useful for advanced manufacturing technology.

Step-by-Step Implementation Guide

Installation of aluminum nitride heaters requires careful planning for optimal results:

Step 1: Evaluation of current heating system

- Measuring temperature uniformity of wafer surface

- Calculate the base value of energy consumption for existing equipment

- Identify problem areas in semiconductor manufacturing processes

Step 2: Select the appropriate AlN heater specification

- Determine the temperature range required for the application

- Calculate the size of the heating element required for the chamber

- Choose the right power rating based on heat requirements

Step 3: Installation Process

- Replace existing heating elements during periodic maintenance

- Calibrate new aluminum nitride heaters and temperature sensors

- Test system performance before mass production starts

How Aluminum Nitride Heaters Improve Manufacturing Quality

AIN heaters can help manufacture better semiconductor products because of the following factors.

Better wafer process

You know that wafer processing requires accurate heating during production.

If the wafer is not heated uniformly, a part of the wafer becomes useless. By using aluminum nitride heaters, heat is transmitted evenly throughout the wafer. This means that more wafers can be made into practical chips. The waste of materials is reduced, and products can be sold more.

As other manufacturers have reported, after switching to aluminum nitride heaters, you may get about 10-15% more operating chips from each wafer.

Improved Crystal Growing

When you’re growing semiconductor crystals, you need steady heat. Even small temperature fluctuations can cause flaws in your final product.

With AlN heaters, you’ll maintain more consistent temperatures. This helps you grow better crystals with fewer defects. Your better-quality crystals will create electronic components that last longer and perform better.

You could experience what other factories using AlN have seen:

- Fewer failed crystal batches

- Higher quality crystals

- More consistent results between production runs

Better Thin Film Making

When you’re depositing thin layers on your chips, you need exact temperatures. AlN heaters give you precise control during this critical process.

Even minor temperature variations can ruin your thin films. With AlN heaters, you’ll achieve fast warm-up times and stable temperatures. This helps you create perfect thin films consistently.

Your thin films will have:

- More consistent thickness

- Fewer defects or gaps

- Superior electrical properties

Advanced Packaging Help

As you create smaller and more powerful chips, packaging them becomes more challenging.

These packages require careful heating to form properly. With AlN heaters, you will control the exact temperature needed for modern chip packages. This ensures your tiny connections form correctly, giving you finished chips that work better and last longer.

Real Industry Experiences

After switching to aluminum nitride heaters, facilities achieve remarkable improvements:

Case Study 1: Semiconductor Fab in Asia.

- Проблема: 35 percent wafer defect rate due to uneven heating.

- Решение: Switched to aluminum nitride heaters.

- Result: Defect rate dropped to 8 percent within 3 months

Case Study 2: Memory Chip Manufacturer

- Challenge: High energy costs (45 percent of operating expenses)

- Implementation: AlN heating system upgrade

- Outcome: 28 percent reduction in energy consumption

Business Benefits When You Use Aluminum Nitride Heaters

AIN heaters can be beneficial as compare to conventional heaters.

Make More Good Products

When you make more working chips from each wafer, you save money. By using aluminum nitride heaters you will produce more good chips and fewer rejects.

You might see 10-15% more working products after you switch to these advanced ceramic heaters. This means more revenue from the same amount of raw materials you’re already using.

Use Less Energy

When you install aluminum nitride heaters, you’ll use less power than with other industrial heating systems. These heaters warm up faster and lose less heat to surrounding areas.

С использованием semiconductor heating solutions like AlN heaters will lower your energy costs and help you achieve your sustainability targets. You might save up to 20% on heating costs after making the switch.

Your Equipment Lasts Longer

Replacing your factory equipment costs you significant money. When you choose aluminum nitride heaters, they’ll last longer than many alternatives.

You might find, like other companies have, that your AlN heaters need replacing 30-50% less often than other types. This gives you less downtime and lower replacement costs over time.

Why Choose Aluminum Nitride Heaters for Modern Manufacturing

You should consider AIN heating technology, because it offers the below stated advantages.

More Advanced Power Electronics

If you are manufacturing electric vehicles, solar power systems, or computer server components, you need a dedicated power chip. These chips need to process more electricity and heat than standard chips.

Aluminum Nitride Heaters help manufacture these dedicated components by providing the high temperature and precise control required for power electronics.

Energy saving is important

When reducing energy consumption to reduce costs and protect the environment, aluminum nitride heaters support that goal. They operate with less power than conventional semiconductor heating solutions.

This is consistent with your sustainability initiatives to help you comply with energy efficiency regulations.

Expert views and industry opinions

According to experts in the semiconductor industry: “Aluminum nitride heaters are becoming the standard technology for next-generation chip manufacturing because of their accuracy and reliability.” Dr. Sarah Chen, material engineering

Industry Trends: 70% of new semiconductor plants adopt aluminum nitride heating technology Future forecast: The aluminum nitride heater market is expected to grow at a CAGR of 35% by 2027.

How to Choose The Right AlN Heater For Your Needs

You must consider the following steps to choose the right AIN heater for your need.

Know Your Process Requirements

Your different chip-making steps need specific types of heating. When selecting AlN heaters, check:

- The maximum temperature you need

- How uniform the heating must be

- The heating and cooling rates you require

- What process environments (gases or chemicals) you’ll be using

Check Compatibility With Your Systems

Any new heaters must integrate with your existing equipment. Consider:

- The dimensions and mounting options you need

- How it will connect to your power supply

- How it interfaces with your control systems

- How easily your team can maintain or replace it

Look at Total Cost of Ownership

The cheapest heater isn’t always your best value. Think about:

- Initial purchase price

- Installation expenses

- Energy consumption over its lifetime

- Expected service life

- Impact on your product quality and yield

While AlN heaters might cost you more upfront, they often save you money through better yields and lower operating costs.

Заключение

By using aluminum nitride heaters in your semiconductor manufacturing, you will produce better products with fewer defects. You will enjoy precise temperature control, longer-lasting equipment, and lower energy bills. For your advanced chip production needs, this industrial heating technology is a smart investment that improves your product quality while reducing your costs over time.

Want to take the manufacturing process to the next level? Consider GGSКерамика premium aluminum nitride heaters and increase productivity today.

Часто задаваемые вопросы

What is aluminum nitride?

Aluminum nitride is a high performance ceramic that you use in harsh thermal environments. The heat is moved quickly and reliably, making it ideal for the process.

What is aluminum nitride used for?

In semiconductor manufacturing, you can use it in heaters to accurately control temperature. This reduces defects and improves your chip quality.

How does ALN Ceramics help me?

ALN ceramics power heaters that keep your production consistent and efficient. They provide better heat control and longer service life, saving you costs over the long term.

Why should aluminum nitride be considered in semiconductor manufacturing?

Aluminum nitride heaters efficiently conduct heat, does not pass electricity, withstands temperature shock and works at temperatures up to 1,000 ° C. These are the qualities you need for precision manufacturing.

Does the AlN heater cost more than other heaters?

Yes, initial investment is higher. However, you will save costs through reduced energy costs, longer life of equipment, and higher production yield.

What problems does aluminum nitride heater solve in my manufacturing process?

These advanced heaters eliminate uneven heating, reduce energy consumption by up to 28%, and minimize equipment downtime caused by thermal shock.

How long does it take to install an aluminum nitride heater in an existing facility?

Installation usually takes 2-3 days during scheduled maintenance, including calibration and testing stages.

How much ROI can you expect from switching to aluminum nitride heating technology?

Most manufacturers realize a 15-25% increase in production efficiency and a 20-30% reduction in energy costs during the first year.