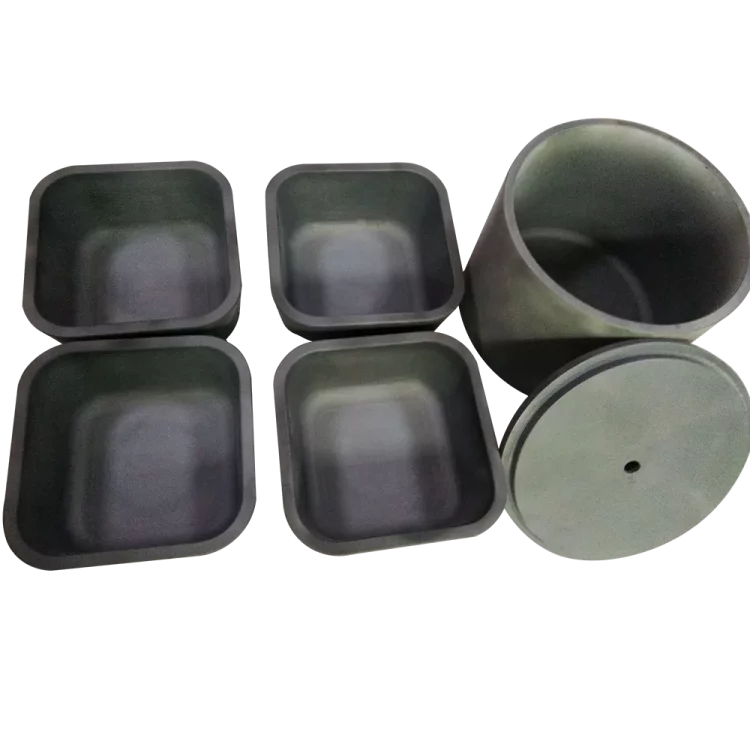

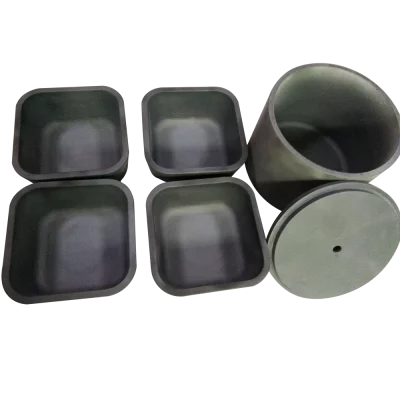

Silicon carbide crucibles are made from high-purity silicon carbide material through isostatic pressing and pressureless sintering.

We customize round, square, flat-bottomed, semi-flat-bottomed, and spherical crucibles for you, and can also add flanges, drilling, and other machining services.

Преимущества производительности

GORGEOUS CERAMICS (GGS) silicon carbide crucibles, due to their submicron-level fine-grained structure and manufacturing process, have smooth surfaces, with raw products achieving Ra < 1.6, which helps prevent corrosion by molten metal.

Our silicon carbide crucibles have a purity > 99%, preventing material contamination.

Our silicon carbide crucibles exhibit excellent thermal stability, withstanding temperatures up to 1700°C in air and 1950°C in nitrogen or argon protective atmospheres.

Polying excellent thermal conductivity and good thermal shock resistance, our silicon carbide crucibles can adapt to rapid changes in process temperature.

Silicon carbide crucibles also exhibit excellent corrosion resistance even at high temperatures, making them particularly suitable for chemically corrosive environments.

![]()

Typical Applications of Silicon Carbide Square Crucibles

Silicon carbide square crucibles are widely used in high-temperature and corrosion-resistant applications, such as: High-temperature calcination of ceramic powders that maintain stable operation at high temperatures for extended periods; Various molten salt systems that retain excellent chemical stability even in a high-temperature molten state; Chemical reactions in highly corrosive and oxidizing media; High-temperature smelting and heat-holding processes for non-ferrous metals and alloys (aluminum, copper, and their alloys).

![]()