窒化ホウ素cbn 優れた特性で知られる先進セラミックです。 BN化学 もっている ホウ素窒素 様々な構造を生み出す結合。BNの構造の中で、特に興味深い構造の一つは 立方晶窒化ホウ素 cbnc-bnとその相対的な側面を理解してみましょう。

目次

窒化ホウ素:概要

窒化ホウ素 化学式「BN」で表されます。前述のように、 窒化ホウ素 様々な形で存在します。一般的に、ホウ素と窒素の格子内の位置によって、様々な 窒化ホウ素の構造。 その中には、非晶質、六方晶、立方晶、ウルツ鉱型など、非常に有名なものもあります。

機能性に関しては、 窒化ホウ素セラミック 機械加工性に優れています。機械加工後は、熱処理や安定化処理をほとんど必要としません。さらに、 窒化ホウ素 熱容量が高く、電気絶縁体としても優れています。

とりあえずBNの導関数を理解してみましょう。 六方晶窒化ホウ素(h-BN) そしてもう一つ 立方晶窒化ホウ素(c-BN)

六方晶窒化ホウ素(h-BN)

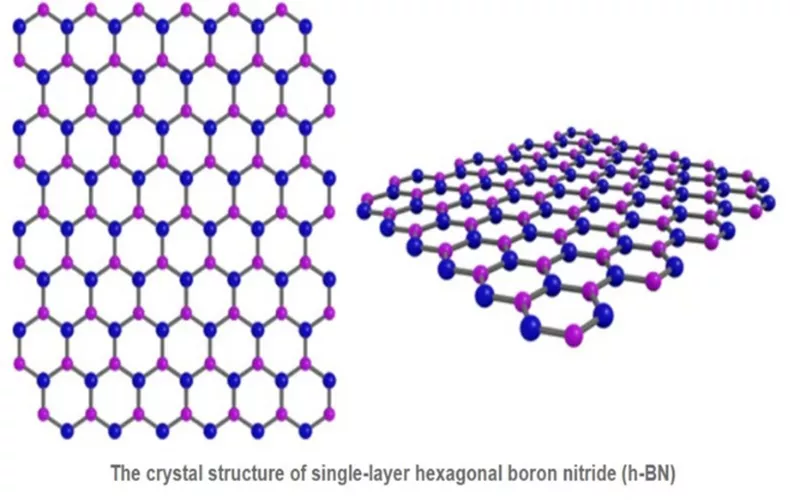

六方晶窒化ホウ素の構造

六方晶窒化ホウ素 化粧品などの多くの工業製品の成分です。HBNは、 共有結合. しかし、HBNの層は さまよえるワールス力. HBN のプレートのような形状が、潤滑に最適である理由です。

六方晶窒化ホウ素 ホウ素と窒素の元素が格子に固定されています。ホウ素原子に3つの窒素原子が結合した構造です。ハニカム構造の類似性が炭素との類似性を生み出しています。さらに、平面三角形の結合により、機械的強度、化学的強度、電気絶縁性といった特性が得られます。

六方晶窒化ホウ素の特性

六方晶窒化ホウ素 高温でのホウ素窒化によって製造されることが多い。その安定性はグラフェンに近いため、 六方晶窒化ホウ素 最も先進的な技術セラミックとして高く評価されています。 六方晶窒化ホウ素 熱伝導性と摩擦係数の低さが特徴です。

六方晶窒化ホウ素の用途

- HBNはナノエレクトロニクスデバイスにおいてグラフェン基板の代替として使用されている。

- 六方晶窒化ホウ素 薄い形では腐食に耐えるコーティングとして使用される

- HBNはセンサー材料の製造によく使用されます。また、誘電率が低いため、電子トンネル効果にも使用されます。

立方晶窒化ホウ素

立方晶窒化ホウ素とは何ですか?

c-BNは 六方晶窒化ホウ素(h-BN) 高温高圧下で製造されます。

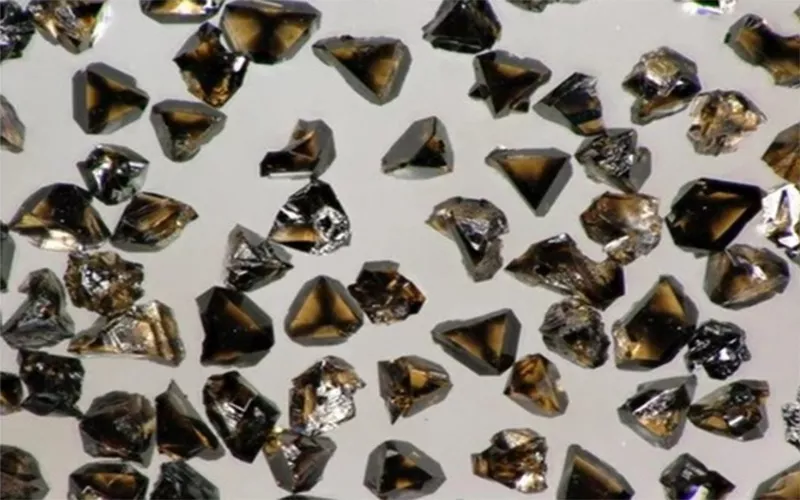

最大の特産品は c-BN 世界で2番目に硬い素材であるという点です。その機械的強度は 立方晶窒化ホウ素 ダイヤモンドと並ぶ人気を誇ります。ホウ素の最も人気のある多形体の一つです。 窒化物.

の構造 立方晶窒化ホウ素

基本構造 立方晶窒化ホウ素 C-BNは結晶性を有し、密度は約3.5 g/cm3で、淡黄色または透明です。C-BNはホウ素原子と窒素原子が交互に配列しています。 ホウ素窒素 原子は共有結合しており、これがその硬さと安定性の基本的な理由です。

立方晶窒化ホウ素の化学式 c-BNとして知られています。現在市場で入手可能なc-Bnには2つの種類があります。1つは高密度の 立方晶窒化ホウ素 もう一つは多結晶立方晶窒化ホウ素です。

立方晶窒化ホウ素の特性

C-BN は、印加圧力によってバンドギャップが変化する優れた半導体です。このバンドギャップの変化により、優れた電気絶縁体として機能します。 立方晶窒化ホウ素 一般的に不活性で、誘電率が低い。熱伝導率は約1300KW/MKである。

反応性に関しては、 c-BN 鉄系材料に対しても反応しない。 立方晶窒化ホウ素 紫外線から可視スペクトルまで変化します。

立方晶窒化ホウ素対ダイヤモンド

ダイヤモンドほど硬くはないが、 立方晶窒化ホウ素 ダイヤモンドと比較すると特別な位置を占めています。 立方晶窒化ホウ素の硬度 は 4500 Kg/mm2 であるのに対し、ダイヤモンドの硬度は約 600 Kg/mm2 です。ヤング率とバルク弾性率の値も同様に 800 – 1000 と 370 – 450 の範囲にあります。

さらに、ダイヤモンドのような構造に関しては、 c-BN 2つの異なる基本原子を持ちます。ダイヤモンドとc-BNの類似性は、一般的に、両者の構造が似ていることに起因します。

立方晶窒化ホウ素の用途

CBN切削工具材料

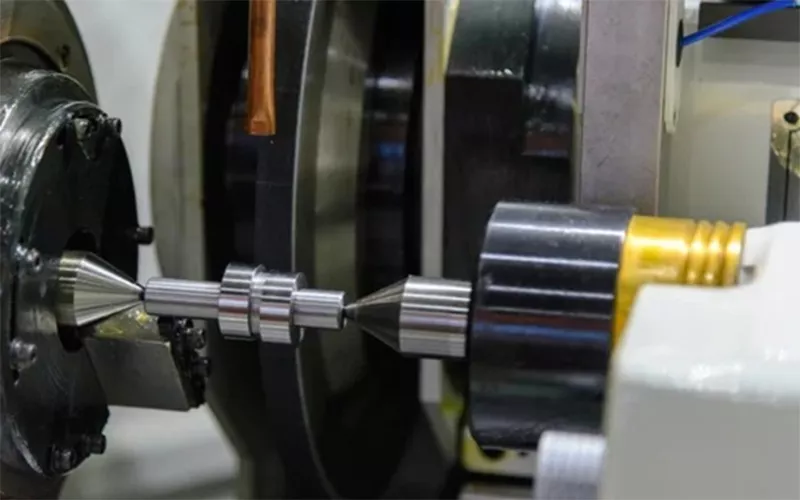

立方晶窒化ホウ素 立方晶窒化ホウ素は、炭化ホウ素や炭化ケイ素よりもヤング率と体積弾性率の両方が優れています。この理由こそが、立方晶窒化ホウ素の硬度に大きく寄与しています。この硬度により、立方晶窒化ホウ素は研磨材として適しており、研磨材として機能します。 CBN切削工具材料一般的に、高密度 c-Bn は切削用途に使用され、多孔質タイプは研削用途に使用されます。

不活性な性質 立方晶窒化ホウ素も 切削・加工材としての機能に役立ちます。ダイヤモンドとは異なり、鉄とは反応しません。しかし、従来のc-Bnを切削用途で使用するには、加工が必要です。これは通常、焼結中にh-Bnからc-Bnへの転化の際に行われます。

電気絶縁体としてのCBN

硬さ以外にも 立方晶窒化ホウ素 電気絶縁体としても優れています。これは、その広いバンドギャップによるものです。

半導体用途におけるCBN

アルミニウムと第8族金属をコーティングすることで、 C-BN シンクになる機能は電子業界で人気があります。 C-BN レーザー、マイクロエレクトロニクスデバイス、LED のヒートシンクとして使用されます。

立方晶窒化ホウ素 半導体合成においても、適切なドーピングによってp型およびn型を得ることで付加価値が生まれます。ドーピングに用いられる一般的な材料はシリコンまたはベリリウムです。これらの半導体は高温で動作し、紫外線センサーなどに用いられています。

c-BN研削ホイール

の発明 c-BN研削ホイール 効率性の向上により精密製造が可能になりました。c-BN で作られたホイールは、航空宇宙、機械、工具製造、自動車などの産業に貢献しました。 c-BN研削ホイール SiCやアルミナと比較して、硬度が高く、優れた性能を発揮します。高温下でも構造の完全性を保ち、劣化も発生しません。

車輪の c-BN 高温に耐え、加工中に発生する熱量に対処します。c-BN砥石を検討する際には、耐摩耗性も経済的なメリットとなります。 c-BN研削ホイールは優れた 表面仕上げが向上し、ワークピースの無駄が削減されます。また、作業が迅速かつ正確に行われるため、サイクルタイムも短縮されます。

超研磨ホイール – またはダイヤモンドc-BNホイール

超砥粒ホイールは、従来のSiCやアルミナ製のホイールとは異なり、C-Bnとダイヤモンドを組み合わせて作られています。超砥粒ホイールは優れた熱伝導性を備え、ワークピースの温度上昇を抑えます。 ダイヤモンドc-Bnホイール また、高精度で精密な切断を実現し、寿命の延長に貢献します。

結論

立方晶窒化ホウ素 現代科学と材料製造において、希土類元素は望ましい存在です。ダイヤモンドなどの材料と比較しても競争力があり、硬度、強度、電気絶縁性といった特性に優れています。また、広いバンドギャップ、不活性、低誘電率、光学特性といった特性も、貴金属の優位性を示す要因です。