Fig 1: Ceramic insulators on power lines

Look up at overhead wires. The brown disk is a isolator keramik that prevents electricity from flying into the metal tower. These isolator listrik ensure the safety of the power system. Knowing the type helps you choose a ceramic electrical insulators suitable for power lines and electrical work.

1. What Are Ceramic Insulators

Ceramic insulators are non-conductive components made from fired clay materials. They prevent current from flowing to unintended places. When you handle electrical systems, these isolator listrik support power transmission lines while separating conductors in power from ground structures.

Its main advantage lies in the atomic structure of ceramic materials. Unlike metals where electrons move freely, ceramic electrical insulators trap electrons in the crystal lattice. This inhibits electrical conduction and makes it an ideal when you need material for reliable high voltage protection.

Modern ceramic insulators use advanced materials such as alumina and silicon carbide. You will find these engineering ceramics perform better than conventional clay materials.

2. Types of Ceramic Insulators

Fig 2: Types of electrical insulators

2.1 Pin-Type Insulators

Pin-type ceramic insulators are mounted directly on power distribution poles using screw-in pins.You will use these ceramic electrical insulators for medium voltage applications up to a maximum of 36 kV. The ceramic body is screwed into a metal pin.

Power companies prefer pin isolator. Because installation is fast and requires minimal maintenance. Ceramic materials do not deteriorate when exposed to weather for decades. If you look at local wires, you can see these ceramic insulators that are actually in operation.

2.2 Suspension Insulators

When handling high voltage transmission lines, you will need a suspension isolator keramik. This is a structure that connects multiple porcelain insulated discs in series like chains. Each disk shares part of the system’s entire voltage.

Modular design enables voltage adjustment by adding and removing disks. If one disk fails, only the corresponding unit can be replaced instead of the entire string. Due to this property, the suspension isolator keramik is cost effective for your various voltage requirements.

You will find these strings correspond to voltages from 69 kV to over 800 kV. Ceramic insulator manufacturers manufacture discs based on precise electrical and mechanical specifications, so you get reliable performance.

2.3 Strain Insulators

At line terminals and sharp angles, you’ll need strain-type ceramic insulators to manage enormous mechanical forces. These power line insulators must support both mechanical and electrical stress caused by conductor weight and wind pressure that you will encounter in actual installation environments.

When you specify strain ceramic electrical insulators, you get reinforced ceramic materials and rugged metal fittings. These can withstand the pulling force that destroys the standard suspension design in your system.

2.4 Specialty Applications

When you are working with electronic circuits, you will need ceramic wire insulators to protect your system from electrical interference. These small components prevent interference between your system components. When you design substations and switching devices, porcelain insulators perform special functions according to the application.

You can use post isolator to provide vertical support in electrical substations. These independent units support your busbars and circuit breakers while maintaining the necessary electrical clearance you need.

3. Common Uses and Applications

3.1 Power Transmission Systems and Insulators for Power Lines

When designing a power supply system, insulators for power lines form the backbone you can rely on. If you manage the distribution grid, you will use them to support electrical lines that carry power to homes and businesses. Your isolator listrik support a wide range of voltages, from 4 kV in residential areas to 765 kV in major power transmission lines.

When you operate a substation, you will rely on thousands of ceramic electrical insulators for safe operation. These facilities convert voltages and switch power between different circuits in your system. The porcelain insulators you will find in substations often exceed 6 feet (about 1.8 meters) in height because they safely handle extreme voltages.

3.2 Industrial Manufacturing

Fig 3: Insulator production warehouse

If you are working with manufacturing facilities, ceramic insulators correspond to high temperature processes. Facilities are operated at temperatures exceeding 1500°C in steel mills, glass factories and chemical plants. Standard plastic materials melt, but ceramic electrical insulators maintain their properties.

Ceramic wire insulators protect the control system from electrical interference. Modern factories rely on computer control that requires clean electrical signals. Industrial applications often require custom ceramic insulators for sale designed for specific operating conditions.

3.3 Transportation Infrastructure

The railway system uses isolator keramiks for safe passenger transport. Trains get power from overhead lines supported by special ceramic electrical insulators. Major city subway systems employ porcelain electrical insulators designed to withstand underground use.

3.4 Communications Systems

In mobile phone base stations and radio stations, ceramic insulators are used to support antennas and isolate powerful transmitters. These applications require insulators with special radio characteristics that do not interfere with signal transmission.

4. Main features and characteristics

4.1 Electrical Performance

Ceramic insulators provide excellent electrical properties for power systems. High quality ceramic electrical insulators withstand more than 20,000 volts of voltage per millimeter thickness. The resistance value is maintained above 10^14 ohm centimeters, making it an excellent electrical barrier even in wet conditions.

4.2 Mechanical Strength

Ceramic electrical insulators withstand compression forces exceeding 400,000 pounds per square inch and also resist wind and ice bending forces. It does not break even under sudden temperature changes and maintains good performance under all weather conditions.

|

Material Property |

Traditional Ceramic |

Advanced Ceramic |

Composite Ceramic |

|

Tensile strength (MPa) |

100-300 |

400-800 |

500-1200 |

|

Operating temperature range (°C) |

-40 to +80 |

-40 to +120 |

-40 to +85 |

|

Dielectric strength (kV/mm) |

15-25 |

20-35 |

12-20 |

|

Hydrophobicity retention |

Bagus |

Bagus sekali |

Superior |

Data source: IEC 61109:2025 standard

Fig 4: Material strength comparison

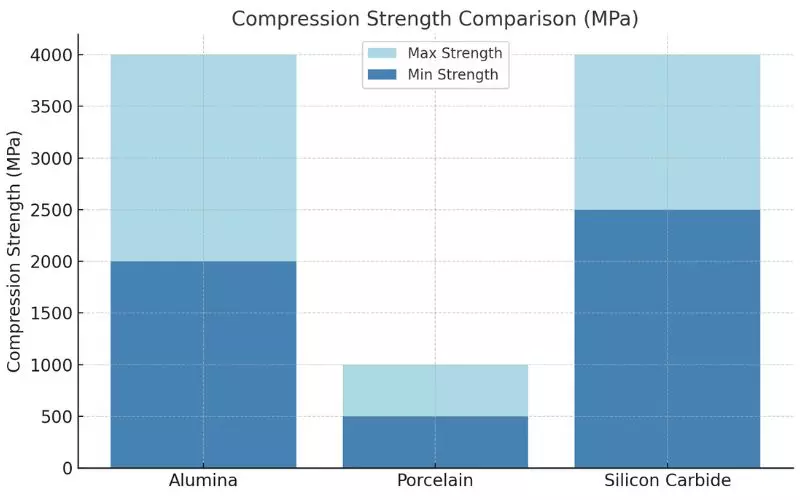

4.3 Material Options

Berbeda bahan keramik each offer their own advantages. Alumina balances optimal properties in general power systems. Porcelain insulators use traditional clay-based ceramics with proven reliability. Silicon carbide ceramic electrical insulators withstand extreme temperatures and, although costly, perform superior performance in harsh applications.

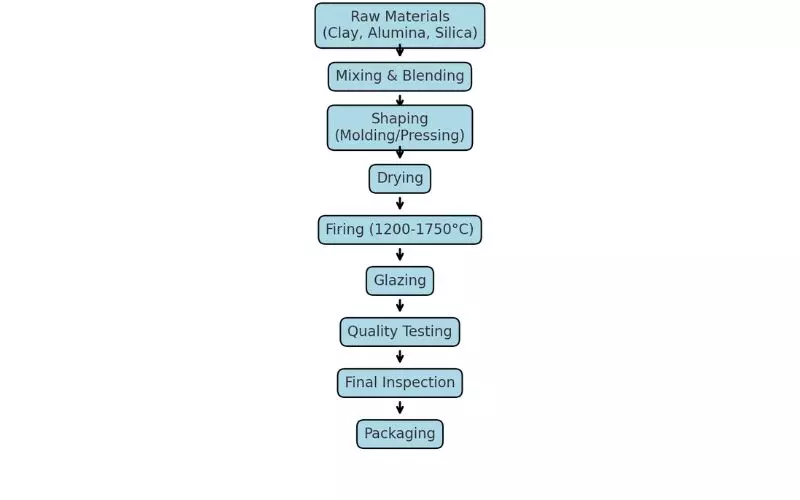

4.4 Manufacturing Process

Making ceramic insulators involves several careful steps to ensure they can handle high voltage safely. The manufacturing process controls quality at every stage.

Fig 5: Ceramic Insulator Manufacturing Process

Manufacturing Process:

-

Raw materials: Precisely weighing clay, alumina and silica powder to keep the quality uniform

-

Mixing and formulation: completely mixing the material to create a uniform mixture

-

Cetakan: Press the mixture with a dedicated mold to form an insulator shape

-

Drying process: The molded insulator is dried slowly to remove all moisture without cracking

-

Firing process: High temperature treatment from 1200 to 1750°C to convert clay to hard ceramic

-

Glaze process: A protective glass coating is applied to increase weather resistance and pollution resistance.

-

Quality inspection: Insulation resistance test and mechanical load test for each lot

-

Final inspection: Check for cracks and defects in individual ceramic insulators

-

Packaging: Finished products are carefully packed to prevent damage during transport

In modern factories, temperature and process time are strictly controlled by computer control systems. This ensures that all ceramic electrical insulators meet strict safety standards for power lines.

5. Advantages of ceramic insulators

5.1 Long Life

Ceramic insulators work reliably for 40 to 60 years with little maintenance required. This is better than plastic, which has only 20 years. High-quality ceramic insulators sold by reliable ceramic insulators manufacturers have long-term warranties that demonstrate the reliability of ceramic technology.

5.2 Weatherproof

Ceramic electrical insulators withstand acid rain, factory pollution,and salt spray. Since the surface repels water and dirt, maintenance work is reduced. Even in coastal areas where other materials are easy to corrode due to sea breeze containing salt, porcelain electrical insulators have excellent performance.

5.3 Safety and Protection Performance

Ceramic insulators provide stable electrical protection without aging. It is non-flammable and always meets safety standards that protect people from electrical hazards.

5.4 Wise Investment

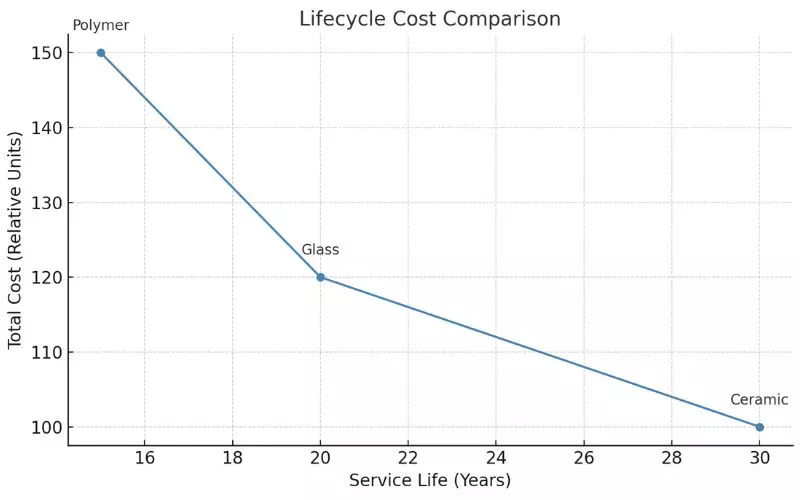

Biaya awal ceramic insulators is higher than that of other products, but it realizes cost reduction over a long period of time. By reducing maintenance costs and decreasing replacement frequency, the purchase price difference is offset during the operation period of the facility.

|

Comparison Elements |

Keramik |

Kaca |

Polymer |

|

Initial expenses |

Sedang |

Rendah |

Tinggi |

|

Masa Pakai |

40-60 years |

25-35 years |

15-25 years |

|

Pemeliharaan |

Rendah |

Sedang |

Tinggi |

|

Overall Evaluation |

Bagus sekali |

Bagus |

Fair |

Fig 6: Cost comparison over lifespan

6. Selection Considerations

When you select the right ceramic electrical insulators, you need to match specifications to your application requirements. In heavily polluted areas, composite insulators may be more suitable than ceramic options. The rated voltage must exceed the system operating voltage with sufficient safety margin. The conditions of the installation environment in your area will affect material selection and insulator design.

The severity of pollution affects the necessary coastal distance requirements. When you operate in industrial and coastal areas, you will need longer surface paths to prevent flashovers under contamination conditions. Ceramic insulator manufacturers can provide you guidance on appropriate selection based on installation location conditions.

You must calculate mechanical loads from conductor weight, wind, and ice for proper insulator sizing. Insulators that lack design can be mechanically damaged in your system, even if they are not electrically problematic.

Pertanyaan yang Sering Diajukan

1. What are the main differences between ceramic and porcelain insulators?

Porcelain insulators use traditional clay materials, while modern ceramics use synthetic compounds such as alumina to improve electrical and mechanical performance.

2. How long can ceramic insulators be used under a normal use environment?

High-quality ceramic electrical insulators usually provide reliable operation for 40 to 60 years if they meet the appropriate installation and minimal maintenance requirements.

3. Can I repair damaged ceramic insulators?

Damaged ceramic insulators cannot be safely repaired, and cracks are subject to electrical hazards and system failure, so they must be replaced immediately.

Kesimpulan

Ceramic electrical insulators provide the performance and durability required for safe and long-term operation of the system. Whether updating existing infrastructure or planning new installations, ceramic materials provide reliable protection. For technical specifications and estimates, please contact the certified ceramic insulator manufacturer.