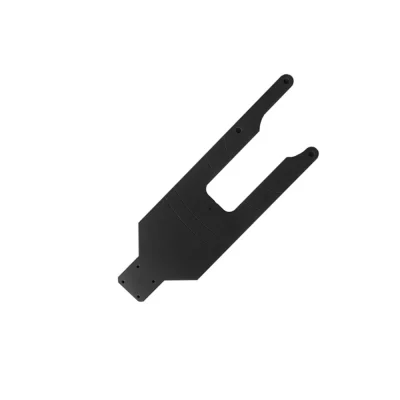

GORGEOUS CERAMICS (GGS) silicon carbide robotic arms are formed using isostatic pressing and high-temperature sintering. We can precision machine the external dimensions, thickness, and shape according to the user’s design drawings to meet specific application requirements.

Performance Advantages of Silicon Carbide Robotic Arms

This silicon carbide robotic arm boasts precise dimensions and thermal stability, making it resistant to bending and deformation even after prolonged use.

It features a smooth surface and superior wear resistance, enabling safe wafer handling without particulate contamination.

GORGEOUS CERAMICS (GGS) silicon carbide robotic arms have a resistivity of 10⁶-10⁸ Ω, are non-magnetic, and meet ESD protection specifications, preventing static electricity buildup on wafer surfaces.

They also possess good thermal conductivity and a low coefficient of thermal expansion.

![]()

FAQ

1.What are the main advantages of silicon carbide ceramic arms compared to quartz or alumina arms?

Silicon carbide ceramic arms offer higher stiffness and superior thermal conductivity than alumina arms. Using silicon carbide ensures better dimensional stability, longer service life, and better performance in high-temperature and plasma environments.

2.Are silicon carbide ceramic arms suitable for high-temperature and plasma processing?

Yes, our silicon carbide ceramic arms possess excellent thermal stability, thermal shock resistance, and plasma corrosion resistance. These properties make silicon carbide ceramic arms an ideal choice for semiconductor processes.

3.How do silicon carbide ceramic arms help improve wafer handling accuracy?

Because silicon carbide ceramic arms have a high elastic modulus and a low coefficient of thermal expansion, they maintain precise geometry even during thermal cycling, thus ensuring the stability of wafer positioning.