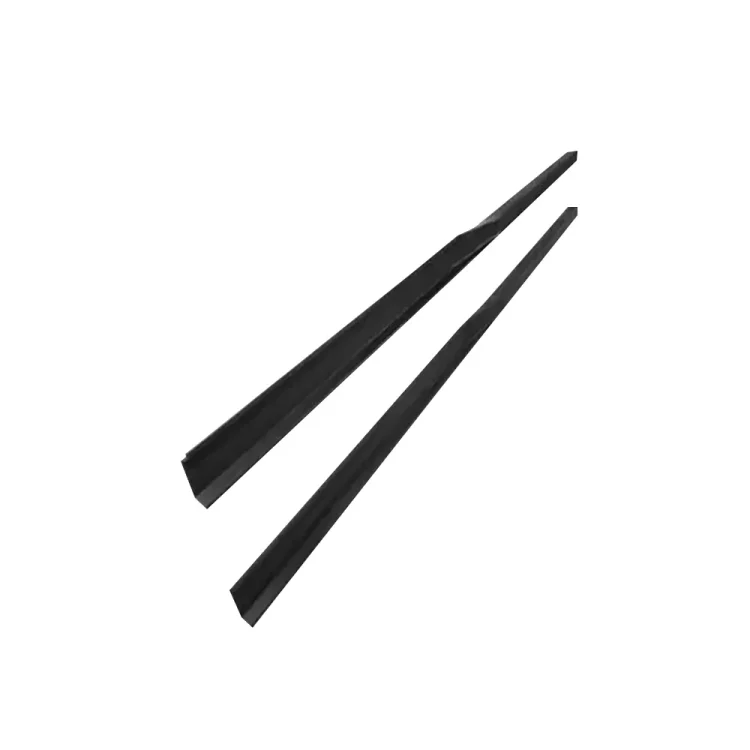

GORGEOUS CERAMICS (GGS) silicon carbide cantilever propellers are made from spray-granulated silicon carbide powder, 3D printed, and reaction-sintered.

We can perform sandblasting and finishing according to customer requirements to meet your needs.

Advantages of Silicon Carbide Cantilever Paddles

![]()

High Temperature Resistance: Operating temperature up to 1300℃, maintaining good structural integrity even at high temperatures, making it suitable for harsh high-temperature environments.

Low Coefficient of Thermal Expansion: carbure de silicium has a low coefficient of thermal expansion, maintaining dimensional stability and minimizing the probability of deformation even under high-temperature conditions and changes in temperature.

Thermal Shock Resistance: It can withstand rapid heating and cooling cycles, reducing the risk of cracking and making it ideal for harsh process environments.

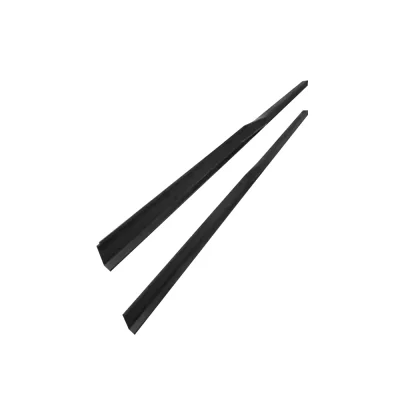

Specifications and Models

GORGEOUS CERAMICS (GGS) can customize models to meet your needs and select processes according to your application requirements, providing you with the best silicon carbide solutions.

FAQ

1. What applications are silicon carbide cantilever propellers suitable for?

Silicon carbide cantilever propellers are mainly used in high-temperature furnaces, diffusion furnaces, and other high-temperature, corrosive atmospheres. They provide an excellent solution for applications requiring prolonged high-temperature operation or frequent thermal cycling.

2. What are the advantages of silicon carbide cantilever propellers compared to quartz or alumina cantilever propellers?

Compared to quartz, silicon carbide has a higher upper temperature limit and better thermal shock resistance, making it less prone to cracking.

Compared to alumina, silicon carbide has higher thermal conductivity and lower thermal stress, making it more suitable for high-temperature processes with rapid temperature rise and fall and long service life.

3. Do your silicon carbide cantilever propellers support customization?

Yes, GORGEOUS CERAMICS (GGS) supports customization. We can customize according to the drawings, equipment structure, and process requirements provided by customers, including aspects such as size, shape, wall thickness, and connection method.