GORGEOUS CERAMICS (GGS) MOCVD silicon carbide coated disks are made from high-purity isostatic graphite through precision machining, high-temperature purification, and chemical vapor deposition.

We can customize them according to your needs and drawings, including dimensions, flatness, and surface roughness.

MOCVD Silicon Carbide Coated Disks Performance Advantages

Ultra-High Purity: We use an ultra-high purity process system to prepare the disks, with a total impurity content of less than 5 ppm, reducing the risk of contamination and meeting the stringent requirements of semiconductor fabrication.

Excellent Deposition Uniformity: We precisely control the coating thickness, with an overall thickness variation of less than 15%, ensuring stable and consistent process performance.

High-Temperature Stability: Maintains good mechanical strength and dimensional stability even under long-term high-temperature environments, and is not prone to deformation or degradation.

Superior Thermal Conductivity: Possesses superior thermal conductivity, enabling uniform and rapid heat transfer.

Corrosion Resistance: Adaptable to various corrosive gases and chemical media, and withstands the complex and demanding reaction environment of the MOCVD process.

Ultra-High Hardness and Wear Resistance: High hardness, long lifespan, and resistant to wear and particle buildup even after long-term use.

Specifications and Models

GORGEOUS CERAMICS (GGS) MOCVD silicon carbide coated trays can be configured to meet different equipment platforms and process requirements. Common sizes include:

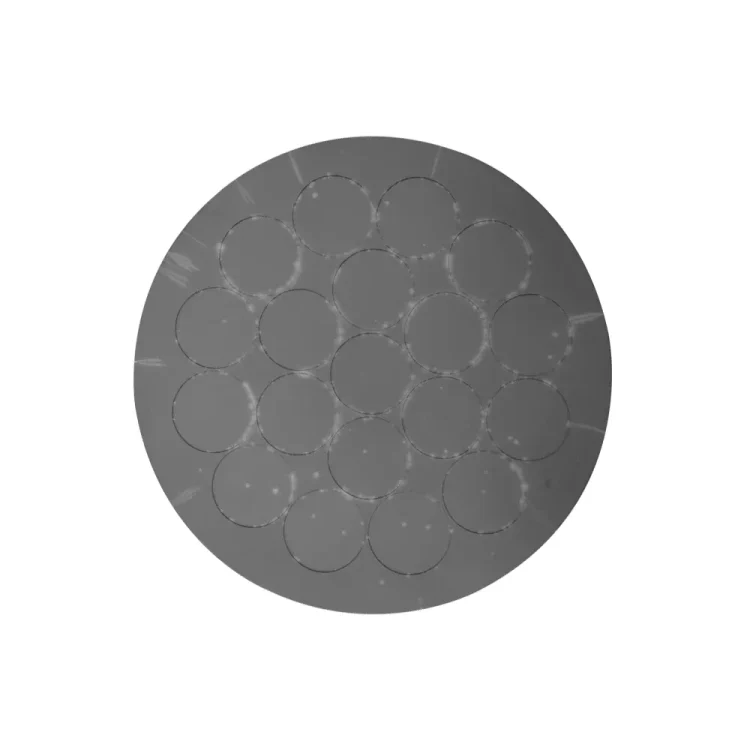

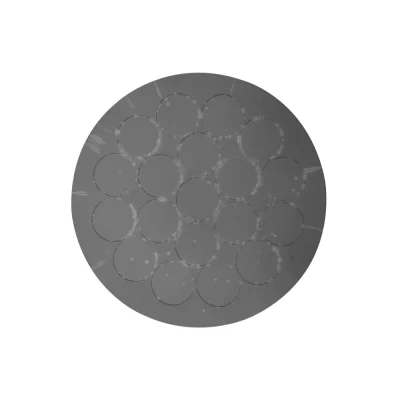

19 trays × 2 inches

14 trays × 4 inches

36 trays × 4 inches

41 trays × 4 inches

FAQ

What are the applications of MOCVD silicon carbide coated disks?

Silicon carbide coated disks are used as wafer supports or substrates in MOCVD reactors, primarily for epitaxial growth processes of GaN, SiC, and other compound semiconductors.

These products can support multiple wafers, ensuring stable temperature control and uniform deposition.

What are the advantages of silicon carbide coatings in MOCVD applications?

Silicon carbide coatings possess high purity, thermal conductivity, heat resistance, and corrosion resistance. These properties help maintain a uniform temperature distribution, reduce particulate contamination, and extend service life during demanding MOCVD operations.

How does coating uniformity affect epitaxial growth quality?

Uniform coating thickness is crucial for achieving consistent heat transfer and stable wafer temperatures. High coating uniformity helps minimize temperature gradients on the disk, thereby improving the uniformity, repeatability, and overall process yield of the epitaxial layer thickness.