Ceramic substrates are indispensable in your electronics in 2025. Their mechanical strength, thermal conductivity, insulation, and heat resistance make your ceramic substrate the backbone of your electronic packaging.

What is Ceramic Substrate?

-

一个 陶瓷制品 substrate is a ceramic material used as the insulating base of your electronic components.

-

陶瓷制品 基材 materials are preferred over metals in your high-performance systems due to their excellent heat dissipation & reliability.

1. Aluminium Nitride Ceramic Substrates

-

你的 aluminium nitride substrate offers 热导率 of 170–200 W/m·K. Together with CTE (coefficient of thermal expansion) <5.3 x 10⁻⁶ K⁻¹, it ensures reliability in your semiconductors.

-

Aluminium nitride’s relative permittivity of 8.8 kV/mm meets IEC 60672-2.

笔记: Its fracture toughness is relatively low (only 2–3 MPa·m½), making it unsuitable for high-impact environments.

“Switching to aluminum nitride in our laser diode packaging slashed junction temperatures by 25 °C.” — Denis O., Engineer, Diolabs

2. Alumina Ceramic Substrate Materials

-

你的 氧化铝 ceramic (Al₂O₃) substrates’ density of 3.99 g/cm³ and thermal conductivity 24-27 W/m·K ensure performance at low cost.

-

Its frexural strength 386 ±12 MPa, and its hardness, 1500 HV, resists wear in your connectors and RF modules.

“Over the years, alumina substrates have provided the right balance of price and performance in our LED packaging. Easy to source…” —Zhi W., materials scientist, Pugma Electronics

3. Silicon Nitride Ceramic Substrates

-

你的 氮化硅 ( Si₃N₄) ceramic substrates’ fracture toughness of 7 MPa·m½, and flexural strength 800-1000 MPa (ISO 20501:2024), offer your products mechanical reliability.

-

Its mechanical resilience supports power modules in your electric vehicles.

4. Silicon Carbide Ceramic Substrates

-

碳化硅 (SiC) ceramic substrate materials offer thermal conductivity of 120 W/m·K, ideal for your semiconductors.

-

Due to their hardness >2500 HV, wear resistance improves. And, their low loss tangent supports your RF uses.

5. Zirconia Ceramic Substrate

-

你的 氧化锆 (ZrO₂) ceramic substrate offers fracture toughness 8–10 MPa·m½. With this kind of resilience, zirconia ensures long-term integrity in your medical electronics and sensor housings.

6. Berilium Oxide Ceramic Substrates

-

氧化铍 substrates with thermal conductivity of up to 230 W/m·K ensure minimal heat buildup and improved efficiency in your RF devices.

Note: Strict handling compliance is required due to BeO’s toxicity when processing it. This makes OSHA 和 RoHS adherence and ISO-certified supply a must.

7. Mullite Ceramic Substrate

-

Mullite offers thermal conductivity of 4 W/m·K and low CTE, making it reliable in your thermal shock application.

-

Mullite ceramic substrates’ density is lower than alumina, lessening weight in your assemblies.

-

Mullite is also researched as a ceramic substrate planting material due to its porosity and thermal stability, supporting controlled root growth in biotech application

Comparison Table of the Features of Ceramic Substrates

|

材料 |

密度(克/立方厘米) |

Thermal Conductivity (W/m·K) |

介电常数 |

CTE (×10⁻⁶ /K ) |

Fracture Toughness (MPa·m½) |

抗弯强度(MPa) |

|

氧化铝(Al₂O₃) |

3.99 |

24-27 |

9.8 |

7–8 |

3-4 |

386 ±12 |

|

氮化铝 |

3.26 |

170-200 |

8.8 |

4.5 |

2-3 |

386 ±12 |

|

氮化硅 |

3.2 |

70 |

8.0 |

3.2 |

7 |

800-1000 |

|

碳化硅 |

3.2 |

120 |

9.7 |

4.0 |

3-4 |

450 ± 15 |

|

氧化锆 |

6.0 |

2 |

25 |

10 |

8–10 MPa·m½ |

800-1000 |

|

氧化铍 |

2.85 |

Up to 230 |

6.5-7 |

7.5 |

1-2 |

280 ± 10 |

|

Mullite |

2.7-3.0 |

5 |

7±1 |

4-5 |

2-3 |

150+ |

Data source: Mater. Sci. Eng. 2025; 109(2): 021004

Source: IEEE Trans. Compon. Packag. Manuf. Technol., vol. 12, no. 2, pp. 21004–21012, Feb. 2025, doi:10.1109/TCPMT.2025.001234.

Applications of Ceramic Substrate Materials

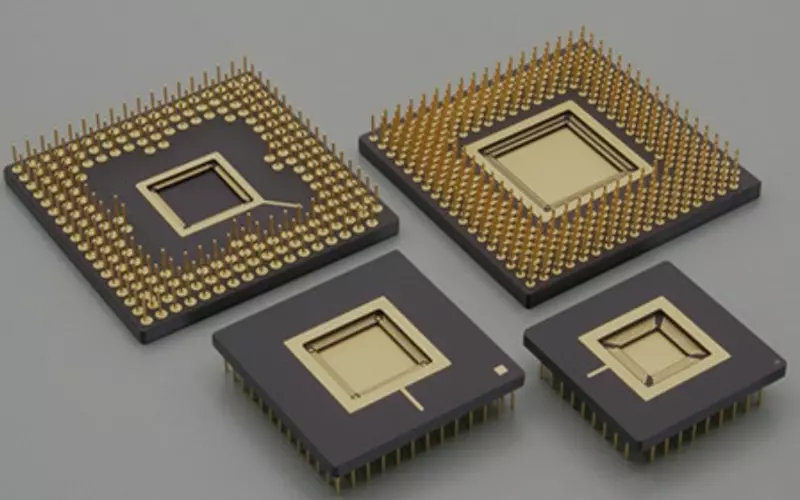

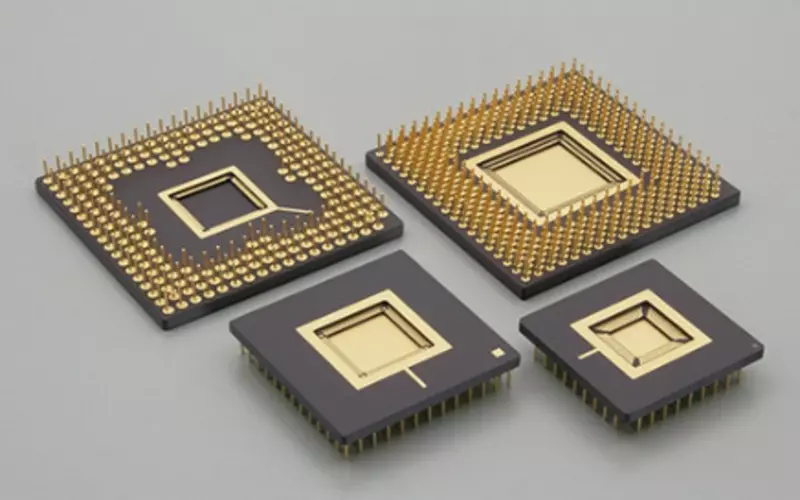

3.1 Ceramic Substrates in Electronic Packaging

-

Your communication modules would wear out and destabilize if polymers are used as substrates. Ceramic substrate materials provide your electronic packaging application with insulation and reliability under harsh conditions.

“Our data modules achieved stable temperatures, and reliability improved by 45% after adopting ceramic substrates.” —Clinton J., Process Engineer, Kenkol Mods

3.2 Electronic Components

-

Your ceramic substrate PCB designs offer your capacitors, resistors, and hybrid ICs high performance. With low dielectric loss and high insulation resistivity, your signals remain pure.

3.3 Power Electronics

-

Aluminum nitride and silicon nitride substrates are ideal for your EV inverters, converters, and high-frequency devices. With their outstanding thermal conductivity, they ensure energy efficiency across power cycles.

-

DBC metallization process requires substrate thermal conductivity >150 W/m·K, making AlN and Si₃N₄ valuable for power cycling reliability.

3.4 Renewable Energy Systems

-

Your solar inverters and wind converters would wear out under continuous loading cycling. Ceramic substrates’ wear resistance and thermal stability prevent failure in your systems.

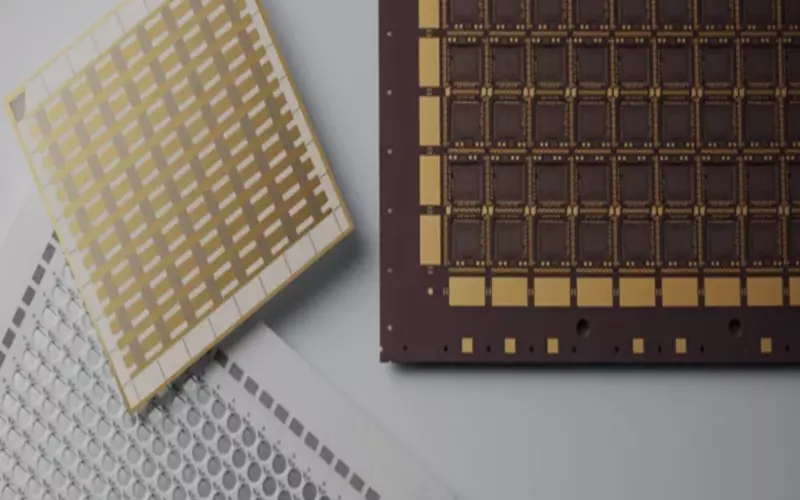

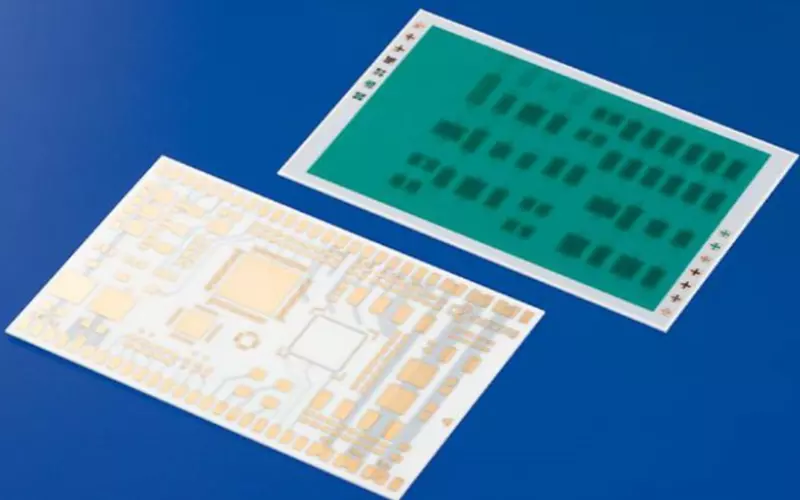

3.5 Ceramic Substrates in PCB Manufacturing

-

Your ceramic substrate PCB (printed circuit board) manufacturing ensures higher dimensional stability than FR-4. Ceramics offer the required performance in your DBC (direct bonded copper) metallization processes.

-

Compared with traditional boards, a ceramic substrate PCB offers higher breakdown voltage and stability for aerospace systems.

3.6 Automotive Catalytic Converter Applications

-

Cordierite ceramic substrate catalytic converters are ideal for your automotive exhaust treatment. Their microporous honeycomb structure ( >400 cells) increases surface area, enhancing catalytic efficiency.

-

Cordierite’s low CTE prevents cracking under rapid heating and cooling cycles.

3.7 Low-Temperature Co-fired Ceramics (LTCC)

-

LTCC substrates are sintered at 850–900 °C, enabling co-firing with conductive metals like silver and copper.

-

They support 50+ layers, with line width accuracy of ±10 μm, making them indispensable for compact RF and aerospace modules.

Leading Ceramic Substrate Manufacturers and Suppliers in 2025

-

Your choice of ceramic substrate manufacturers impacts product quality and compliance.

What to Look For in Ceramic Substrate Suppliers/ Manufacturers

-

Check for quality certifications (ISO 9001, ISO 14001, IATF 16949, and RoHS) to ensure compliance. Also, confirm ASTM C1161 flexural strength, ISO 20501 fracture toughness, and ASTM C1327 hardness.

-

Customization of thickness, geometry, and metallization is also key.

Select GGSCERAMIC® for ISO-certified ceramic substrates and tailored solutions for your electronic packaging.

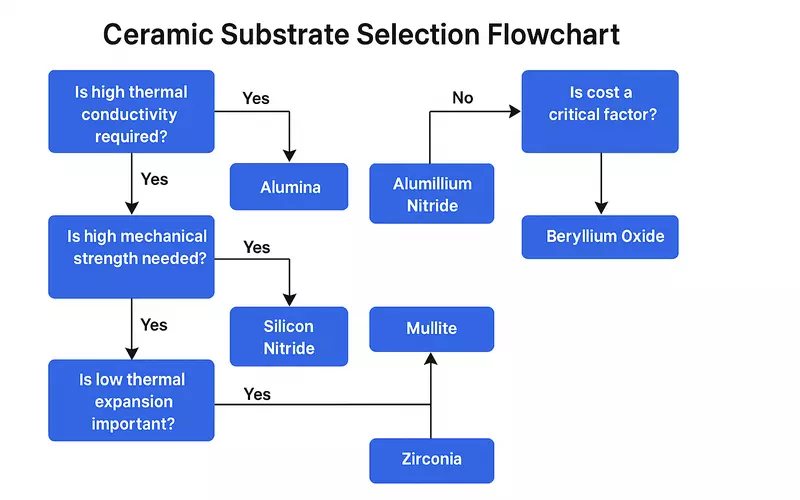

Which Ceramic Substrate Material To Choose

-

The right ceramic substrate depends on the thermal, mechanical, and dielectric demands if your process.

Ceramic Substrate Selection Flowchart

FAQs About Ceramic Substrate Materials

Q: What ceramic substrate materials are chosen for electronic packaging?

A: Select ISO-certified alumina, aluminum nitride, and silicon ceramic substrates in 2025 for balanced thermal, mechanical, and dielectric properties.

Q: What is ceramic substrate catalytic converter material?

A: Cordierite ceramic substrate provides high porosity and low expansion for your automotive catalytic converters.

Q: What is ceramic substrate PCB used for?

A: A ceramic substrate PCB supports your circuits in high-temperature, high-frequency, and high-power applications with stable dielectric performance.

Q: How do ceramic tubes and ceramic washers support electronics?

A: They insulate, withstand wear, and provide structural support in your high-voltage and high-temperature assemblies.

Q: How is ceramic substrate porosity tested?

A: Substrate porosity testing follows ASTM C373, measuring water absorption and open pore volume. This ensures consistency in your catalytic converter cordierite and porous ceramic tubes.

结论

Ceramic substrates’ insulation, conductivity, and reliability are redefining reliability in your electronics in 2025. Select ISO-certified solutions from ggsceramic to ensure your product survives heat, vibration, and lifecycles.