Silicon Carbide Crucible Performance and Advantages in Semiconductor and Photovoltaic Crystal Growth!

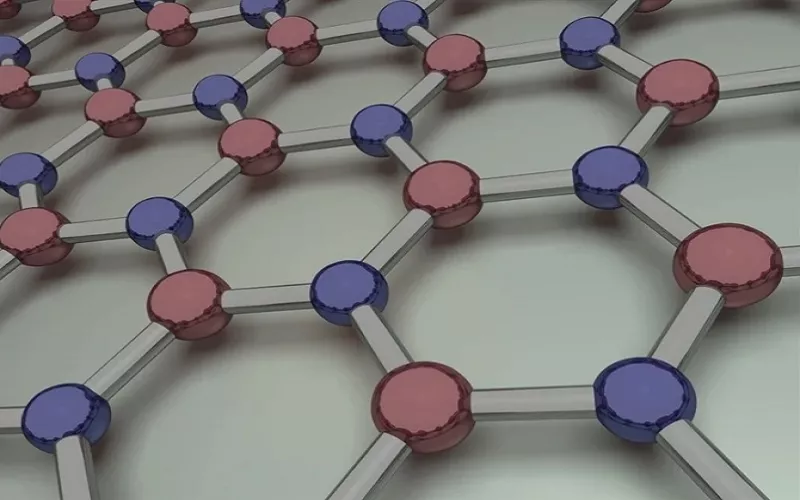

Material quality and process stability are crucial in modern industries. If you are a crystal growth operator, you already know how the purity of your crucible materials impacts your process. Let’s explore how the performance, advantages, and uses of the silicon carbide crucible could benefit your manufacturing process. What Is a Silicon Carbide Crucible? The silicon carbide crucible is a highly durable container you can use in advanced material melting and refining. It offers you an extremely pure and stable state at a high temperature above 1700 degrees Celsius. A silicon carbide crucible is actually a very hard ceramic compound. […]

2026-02-11