Most ceramics crack or melt above 1400°C. 碳化硅 keeps working at temperatures up to 1600°C. This guide covers SiC material properties, manufacturing methods, and actual applications in the aerospace, defense and industrial fields. You’ll understand what makes 碳化硅 陶瓷 and how to select suitable materials according to the application.

What Is Silicon Carbide Ceramic?

Figure 1: Raw Silicon Carbide

You get 碳化硅(SiC) when silicon and carbon atoms bond together in a crystal structure.

You’ll hear it called an ultra-high temperature ceramic because it works continuously at 1600°C. This temperature is high enough to melt most metals and crack standard ceramics.

你的 SiC材料 combine rare properties: 9.5 莫氏硬度, excellent thermal conductivity, low thermal expansion, and chemical resistance.

Aerospace heat shields, semiconductor equipment, and industrial furnaces use it. Nothing else survives these conditions reliably. Nothing else survives these conditions reliably.

How Is Silicon Carbide Manufactured?

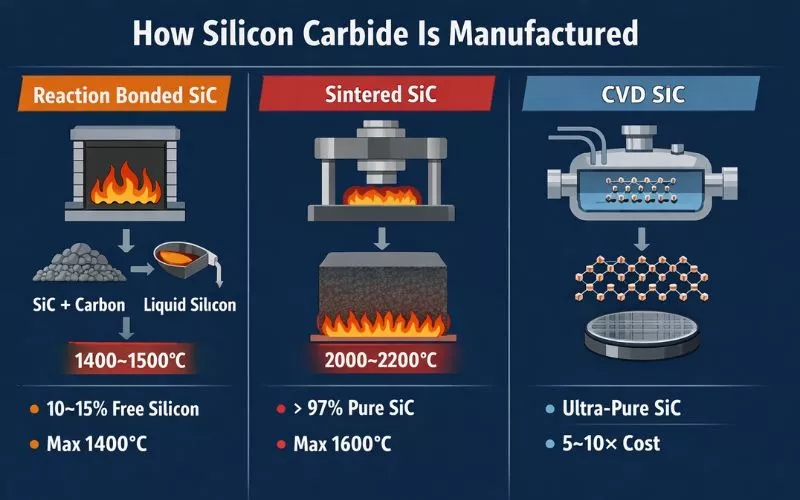

Figure 2: How SiC Is Made

You can’t dig 碳化硅 out of the ground. It doesn’t exist in nature in useful amounts. You have to make it using three different methods.

Reaction Bonding (RB-SiC)

You mix silicon carbide powder with carbon and heat it to 1400°C while adding liquid silicon.

Your parts come out almost ready to use with little machining needed. However, 10-15% silicon remains inside. This means you can only use them up to 1400°C.

烧结 (SSiC)

You mix silicon carbide powder with special additives and press it to the desired shape. Then bake it at 2000-2200°C under high pressure.

This gives you the purest 碳化硅 with a purity of 97% or higher. You can run these parts at full 1600°C all the time. What’s the downside? They cost more and they’re harder to cut or shape after baking.

化学气相沉积 (CVD)

One atom of crystalline silicon carbide at a time is grown out of gases. This creates the best material that is pure and has the best performance.

CVD-SiC is used in semiconductor equipment where purity is of the greatest concern. Should cost 5-10 times higher than sintered types.

It depends on three things, how hot you have to go, how pure you have to go and what you can afford. Reaction-bonded 碳化硅 is the cheapest, and it limits at 1400deg C. Fires sintered at high temperature. CVD is the most expensive though the best performer.

What are the key Properties of Silicon Carbide?

Here’s what you get with silicon carbide properties:

|

What You Need to Know |

碳化硅 |

氧化铝 |

Why This Matters to You |

|

How hot can it go? |

Up to 1600°C |

Up to 1700°C |

SiC stays strong at extreme temperatures |

|

How well does it spread heat? |

120 (very high) |

25-30 (moderate) |

SiC moves heat 4 times faster so you get fewer hot spots |

|

How hard is it? |

9.5 Mohs scale |

9.0 Mohs scale |

Great for wear resistance when things rub against it |

|

Does it expand when heated? |

Very low expansion |

Higher expansion |

Low expansion means it handles sudden temperature changes better |

|

How strong is it? |

400-550 (high strength) |

300-400 (good strength) |

SiC can take more mechanical stress and load |

|

How heavy is it? |

3.1 (lighter) |

3.9 (heavier) |

Lighter parts work better for aerospace |

|

What does it cost? |

$50-150 per kg |

$10-30 per kg |

SiC costs 3-5 times more than standard ceramics |

Why Choose Silicon Carbide for Extreme Environments?

Temperature Performance

你的 silicon carbide ceramic maintains mechanical strength in continuous use up to 1600 °C. Most ceramics soften or creep at such high temperatures, but SiC remains rigid.

This lets you run processes that would destroy other materials.

Oxidation Resistance

At more than 1200°C in the air, 碳化硅 forms a protective layer of silicon dioxide (SiO₂) on the surface. This layer is self-healing.

If it cracks, fresh 碳化硅 underneath oxidizes to seal the breach. Your parts last years instead of months in oxidizing atmospheres.

化学惰性

Acids don’t attack 碳化硅. Bases don’t dissolve it. Molten metal does not get wet (excluding molten silicon).

You can use silicon carbide parts in chemical processing equipment and metal casting applications where other ceramics deteriorate early.

抗热震性

The low coefficient of thermal expansion prevents 碳化硅 from cracking even at temperatures above 1000 °C. Red hot silicon carbide parts can be cooled rapidly in water.

If you try this with most ceramics, it will be an expensive gravel.

耐磨性

At 9.5 Mohs hardness, 碳化硅 has excellent wear resistance.Your mechanical seals run longer and slurry pump parts can be used for several years.

Even under continuous particle impact, blast nozzles maintain tight tolerances.

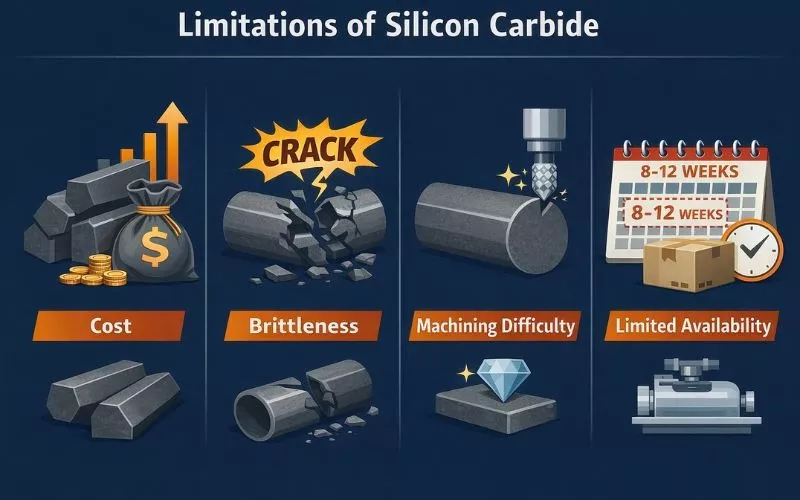

What Are Silicon Carbide’s Limitations?

Figure 3: Silicon Carbide Limitations

成本

The cost of silicon carbide materials is 50-150 dollars per kilogram, 3-5 times that of alumina, 10-20 times that of standard refractories. Your parts will cost hundreds to thousands of dollars each.

If you’re operating below 1400°C, you’re probably overpaying for 碳化硅. Alumina can accommodate most applications up to 1600 °C, greatly reducing costs.

Brittleness

什么时候 silicon carbide ceramic parts are dropped, it is crushed. You can’t weld it if it cracks. It suddenly breaks without signs.

Your handling procedures need to account for this. Please be careful when installing and loading.

Machining Difficulty

You’ll need diamond tooling to machine SiC after firing material removal is slow and tool wear is high. High cost methods such as CVD coating and special molding are required for complex shapes.

Limited Availability

You can’t get silicon carbide parts overnight like alumina or zirconia. It takes 3-4 weeks for standard grade and 8-12 weeks for custom parts.

Plan your ordering ahead to avoid delays.

Where Is Silicon Carbide Used in Extreme Conditions?

航空航天应用

Figure 4: Aerospace Turbine Components

碳化硅 heat shields and nose cone components are used for spacecraft reentry. These components are exposed to 1650 °C in flight at Mach 25, but there is no other material that can withstand this combination of extreme temperature, oxidation and thermal shock.

Rocket nozzle liners are often made of 碳化硅. The exhaust flow reaches 3000°C, but the nozzle operates from 1400 to 1600 °C depending on the cooling design.

Defense Applications

Figure 5: Silicon carbide armor tile

碳化硅陶瓷 tiles are used on bulletproof armor plates. The extreme hardness of the SiC armor plate is 20% lighter than boron carbide, defeats armor-piercing projectiles and the weight can be managed by low density.

For high temperature sensors and infrared windows, crystalline silicon carbide is used for the aiming system.

半导体制造

Figure 6: Semiconductor wafer processing equipment

碳化硅 and wafer carriers are mainstream in high temperature 半导体 processes. When growing a gallium nitride thin film at 1200°C or processing a silicon wafer at 1100 °C, materials that do not contaminate the product are required.

CVD coated 碳化硅 provides the ultimate cleanliness for advanced chip production. Yes, it costs between $5,000 and $10,000 per susceptor. However, when a single contamination event scraps a wafer lot in a single pollution accident, the loss will be more than ten times.

工业应用

Figure 7: Industrial SiC Parts

碳化硅加热元件 power industrial furnaces from 1200-1600°C. Your glass melting furnaces, ceramic kilns, and heat treatment operations run on 碳化硅 elements because metal fails above 1300°C.

These elements last 3-5 years versus 12-18 months for metal alloys. You’re paying more upfront but replacing them half as often.

How Do You Select Silicon Carbide Components?

Start with your maximum operating temperature. That cuts out some options right away.

-

Below 1400°C: Use reaction-bonded SiC (RB-SiC). Costs less than sintered types and easier to machine. The 10-15% leftover silicon limits max temperature but works fine for you.

-

1400-1600°C: You need sintered silicon carbide (SSiC). Higher purity handles full temperature range. Costs 30-50% more than reaction-bonded.

-

Above 1600°C or need extreme purity: 化学气相沉积 碳化硅 becomes your only choice. Costs 5-10x more than sintered 碳化硅.

-

Look at your max continuous temperature first. Then check how often you heat and cool, plus what atmosphere you run in.

-

Pick suppliers with ISO 9001 certification minimum. Aerospace needs AS9100. Ask for test data on thermal, mechanical, and chemical properties.

-

Standard sintered 碳化硅 works for most industrial jobs unless you need semiconductor-level purity or run above 1500°C.

Match your SiC grade to what you actually need. Don’t pay extra for features you won’t use.

What Maintenance Extends Silicon Carbide Life?

Temperature Control

Never run your parts hotter than their rated temperature. Every 50°C over spec cuts your life in half. Put thermocouples at several spots to monitor temperature. Your 碳化硅加热元件 might handle 1600°C, but pushing them to 1650°C for more output means they’ll fail sooner.

Thermal Shock Management

碳化硅 handles temperature swings better than most ceramics, but quick changes still damage it. Heat up and cool down slowly. A 300°C/hour rate works for most jobs. Going faster can crack parts, especially big ones.

Physical Protection

Dropping parts is your biggest problem. Train your crew to handle silicon carbide parts carefully. One dropped piece costs hundreds or thousands of dollars.

Inspection Schedule

Check 碳化硅 components every three months for cracks, wear, or size changes. Small cracks get bigger over time. Swap parts at 80% of their expected life instead of waiting for them to break.

FAQ’s

What factors determine the price of silicon carbide?

Prices are based on three factors: manufacturing method, purity level, and component complexity. Reaction-bonded SiC is $50-80/kg. Sintered grade is $80-120/kg. Silicon carbide reaches $150-300/kg. Custom shapes are increased by 30-50% to the standard catalog price.

Can metal alloy be replaced with silicon carbide in my application?

When operating at 1300 °C or higher, 碳化硅 is likely to be the only option. Metal alloy deteriorates at this temperature. Compare the total cost of ownership at less than 1300 °C. Although the initial cost of metal is cheap, 碳化硅 lasts 3-5 times longer.

What are the characteristics of SiC compared to alumina?

碳化硅 has four times the thermal conductivity of alumina and costs 3-5 times. At less than 1400 °C, alumina with sufficient performance at low cost is suitable. High prices of 碳化硅 are also justified when thermal conductivity is required at 1400°C or higher.

What causes silicon carbide parts to fail?

You’ll damage 碳化硅 three main ways: exceeding maximum temperature, thermal shock with rapid temperature changes, or physical impact during handling. This roughly doubles every 50°C over spec.

What industries use silicon carbide most?

碳化硅陶瓷 are used in thermal shields for aerospace, armor and sensors for defense, semiconductor wafer processing equipment, heating elements for industrial furnaces, ceramic manufacturing kilns, etc.

Can silicon carbide be processed after manufacturing?

It is possible. However, diamond tools are required. SiC’s 9.5 Mohs hardness makes it one of the hardest materials you can machine. Material removal rates are slow and tool cost is high. Many manufacturers adopt near-net shape design during molding.

Is silicon carbide worth the high cost?

It is valuable only when extreme purity is required for semiconductor applications or optical properties for infrared windows are required. In standard industrial heating applications, sintered 碳化硅 provides equivalent high temperature performance at a cost of one-fifth.

How long is the life of a silicon carbide heating element?

Three to five years is estimated for continuous operation at a rated temperature. Operating at or below the maximum temperature greatly extends the lifetime. Operating at a temperature 100 °C lower than rated will double the service life.

结论

Your extreme temperature applications above 1400°C demand 碳化硅陶瓷. Choose your grade based on operating temperature and purity requirements. Sintered 碳化硅 supports most industrial applications at reasonable cost.

Do you have any problems with selecting silicon carbide parts? GORGEOUS CERAMIC(GGS Ceramic) has been manufacturing SiC parts since 2006. 联系我们 to discuss your specific requirements.