Yarıiletken Seramikler

From wafer processing, vacuum adsorption, precision assembly to high temperature processes, GORGEOUS provides customers with one-stop customized semiconductor ceramic solutions.

Precision Ceramic Structural Parts

Pan-Semiconductor Industry

Semiconductor Ceramics Description

Advanced ceramics are a critical part of semiconductor manufacturing equipment. A large amount of plasma is generated during the semiconductor manufacturing process, and it is crucial to use plasma-resistant materials as equipment components. Compared with metals, resins, and glass, advanced ceramics are more high-performance and reliable. Their resistivity is usually between conductors and insulators, and their electrical insulation is excellent, making them very suitable for semiconductor manufacturing processes.

We provide you with all the ceramic materials you need:

✅Alümina (Al2O3) — Ultra-high purity and rigidity;

✅Aluminum nitride (AlN) — Excellent thermal conductivity and insulation;

✅Silisyum nitrür (Si3N4) — Ultra-high fracture toughness and low thermal expansion coefficient;

✅Silicon Carbide (SiSiC)— Low density and coefficient of thermal expansion.

Based on your needs, we can recommend the best material for you to create ultra-high precision semiconductor ceramic components for you!

Üretim ve Kargo Süresi Garantisi

GORGEOUS cooperates with several leading international logistics companies to produce for you quickly and deliver the products to you on time and intact!

Seramiklerin üretimi ve nakliyesi, süreçten ve konumunuzdan etkilenir. Planınıza göre bunları sizin için hızlı bir şekilde üreteceğiz ve en iyi nakliye yöntemini seçeceğiz. Kuzey Amerika'daki en hızlı hava teslimatı, 7 günde ulaşır.

The logistics companies we cooperate with include:

- MSC (Akdeniz Nakliye Şirketi)

- Maersk

- CMA CGM

- KOZKO

- Hapag-Lloyd

- DHL

- GÜÇ KAYNAĞI

- FedEx

- TNT

Daha düşük fiyatlarla verimli nakliye seçenekleri garantilemek için birden fazla nakliye acentesiyle çalışıyoruz. zamanında teslimat, Ve gizli ücret yok!

Üretme

Paketleme

Yükleniyor

Toplu taşıma

Main Properties of Semiconductor Ceramics

Yüksek Sertlik

Aşınmaya dayanıklı

Korozyona dayanıklı

Yüksek Sıcaklık Direnci

Güçlü Yalıtım

GORGEOUS Özelleştirilebilir Ürün Doğruluk Referansı

| Processing Technology | parameter | Achievable accuracy |

| Frezeleme | Flatness, parallelism, Ra | Ra≥0,05 μm” Flatness<1μm |

| Bileme | Flatness | 5 μm < Ø 200 mm / 10 μm > Ø 200 mm |

| Pürüzlülük | Ra from 0,15 μm to 0,6 μm | |

| Paralellik | 5 μm < Ø 200 mm / 10 μm > Ø 200 mm | |

| Eroding | Symmetrical | Max. 0.05mm (hole/positioning slot) |

| Cilalama | Flatness, Parallelism, Roughness | Ra0.06μm-0.35μm Flatness<2μm Parallelism<2μm |

| Structuring | Pürüzlülük | Roughness < 3,2 μm Size < 150 μm |

*Belirli doğruluk, gerçek ürün malzemesi, şekli ve proses gereksinimlerine göre belirlenmelidir.

Semiconductor Ceramic Optional Process

| Product Type | Special Requests |

| Seramik Alt Tabaka | Polishing, metallization coating, gold plating |

| Seramik Kol | Mirror polishing, ventilation slots, anti-static coating |

| Ceramic Rings/Gaskets | Sandblasting, Teflon coating, surface coating |

| Seramik Tüp | Inner wall polishing, hot isostatic pressing, surface coating |

| Ceramic Suction Cup | Micro hole processing, blind hole processing, adsorption vent design |

| Ceramic Heating Element | Metallized coating, surface glaze, antistatic coating |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Customized Semiconductor Ceramic Material Parameters and Selection

| Öğe | Birim | Silisyum Nitrür |

| Yoğunluk | g/cm3 | >3.2 |

| Sertlik | – | HRA90 |

| Vickers Sertliği (Hv50) | YüksekV0.5 | >1550 |

| Elastiklik Modülü | Not ortalaması | 290 |

| Eğilme Dayanımı | MPa | >600 |

| Basınç Dayanımı | MPa | 2500 |

| Kırılma Tokluğu | Milletvekili1/2 | >6.0 |

| Maksimum Kullanım Sıcaklığı | ℃ | 1200 |

| Isıl İletkenlik | H /(M·K) | 15-20 |

| Isıl Genleşme Katsayısı | 10-6 /℃ | >3.1 |

| Isıl Şok Direnci | △T℃ | 500 |

| Özgül Isı Kapasitesi | KJ/kg·K | 700 |

| Dielektrik Dayanımı | kV/mm | 1 |

| Dielektrik sabiti | sen | – |

| 20℃'de Hacim Direnci | Ω.cm | 1,0×1012 |

| Öğe | Birim | Basınçsız Sinterlenmiş Silisyum Karbür | Reaction Bonded Silicon Carbide | Recrystallized Sintered Silicon Carbide |

| Maksimum Çalışma Sıcaklığı | ℃ | 1600 | 1380 | 1650 |

| Yoğunluk | g/cm3 | >3.1 | >3.02 | >2.6 |

| Gözeneklilik | % | <0.1 | <0.1 | 15% |

| Bükülme Gücü | MPa | >400 | 250(20℃) | 90-100(20℃) |

| MPa | – | 280(1200℃) | 100-120(1100℃) | |

| Elastiklik Modülü | Not ortalaması | 420 | 330(20℃) | 240 |

| Not ortalaması | – | 300(1200℃) | – | |

| Isıl İletkenlik | W/m.k | 74 | 45(1200℃) | 24 |

| Isıl Genleşme Katsayısı | K-1×10-6 | 4.1 | 4.5 | 4.8 |

| Vickers Sertliği | Not ortalaması | 22 | 20 | – |

| Acid and Alkali Resistance | – | excellent | excellent | excellent |

| Mülk | Birim | AL2O3 99.7 | AL2O3 99.5 | AL2O3 99 | AL2O3 95 |

| Saflık | — | 99.7% | 99.5% | 99% | 95% |

| Yoğunluk | g/cm3 | 3.92 | 3.9 | 3.8 | 3.7 |

| Bükülme Gücü | MPa | 375 | 370 | 340 | 304 |

| Basınç Dayanımı | MPa | 2450 | 2300 | 2250 | 1910 |

| Elastiklik Modülü | Not ortalaması | 380 | 370 | 330 | 330 |

| Kırılma Tokluğu | Milletvekili1/2 | 4.5 | 4.3 | 4.2 | 3.8 |

| Sertlik | İnsan Hakları Derneği | 91 | 91 | 90 | 89 |

| Vickers Sertliği | Yüksek V1 | 1600 | 1550 | 1450 | 1400 |

| Isıl Genleşme Katsayısı | 10- 6 K-1 | 7.8 | 7.8 | 7.7 | 7.5 |

| Isıl İletkenlik | W/mk | 32 | 32 | 25 | 25 |

| Termal Şok Kararlılığı | △T.℃ | 220 | 220 | 200 | 200 |

| Maksimum Çalışma Sıcaklığı | ℃ | 1750 | 1750 | 1700 | 1500 |

| 20℃'de hacim direnci | Ω·cm | 1015 | 1015 | 1014 | 1014 |

| Dielektrik Dayanımı | kV/mm | 22 | 20 | 16 | 15 |

| Dielektrik Sabiti (oda sıcaklığı) | / | 10 | 11 | 11.5 | 11 |

| MHz Dielektrik Kayıp Faktörü | bronz δ | 1×10-3 | 1×10-3 | 3×10-3 | 3×10-3 |

| Öğe | Birim | Alüminyum Nitrür |

| Yoğunluk | g/cm3 | 3.31 |

| Elastiklik Modülü | Not ortalaması | 310 |

| Kırılma Tokluğu | MPa × m1/2 | 3.5 |

| Poisson oranı | – | 0.25 |

| Compressive | MPa | 2100 |

| Eğilme Dayanımı | MPa | 335 |

| Sertlik (Vickers) | Not ortalaması | 11 |

| Hardness (Knoop 100g) | Kg/mm2 | 1170 |

Özelleştirilebilir Seramik Şaft ucu Tip Referansı

Alumina material products

❇️Wafer Polishing Plates:High hardness and wear resistance ensure high precision and long life of wafer polishing.

❇️End Effectors / Wafer-Handling:Excellent mechanical strength and chemical stability, suitable for wafer handling in high-cleanliness environments.

❇️Metalised Products:Good electrical conductivity and high temperature resistance, suitable for high power electronic devices.

❇️Chamber Rings / Sputtering Targets:High purity and corrosion resistance ensure the stability and consistency of the thin film deposition process.

Silicon Carbide Material Products

❇️Wafer Polishing Plates:Extremely high hardness and thermal conductivity, suitable for efficient and high-precision wafer polishing.

❇️Electrostatic Chucks:Excellent thermal conductivity and electrical insulation ensure stable adsorption of wafers at high temperatures.

❇️Vacuum Chucks:High strength and heat resistance, suitable for wafer fixing in high vacuum environment.

❇️End Effectors / Wafer-Handling:Lightweight and highly rigid, suitable for high-speed, high-precision wafer handling.

❇️Chamber Rings:Excellent high temperature and corrosion resistance, suitable for harsh semiconductor process environments.

What are The Uses of Semiconductor Ceramics?

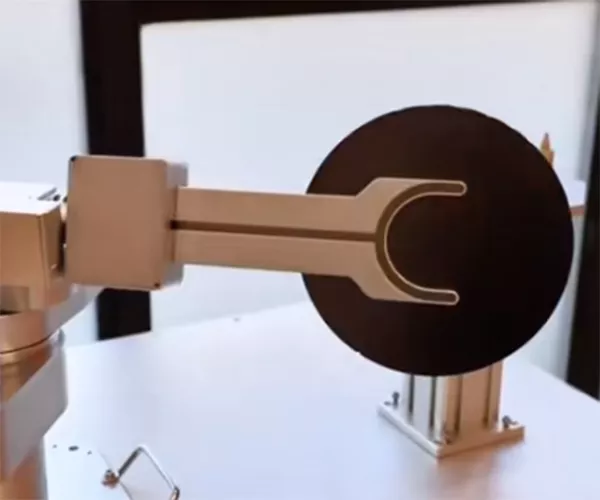

Ceramic Robot Arm/Ceramic End Processor

The ceramic arm plays the role of conveying and carrying in semiconductor equipment, which is equivalent to the arm of the robot of semiconductor equipment. It is mainly responsible for transporting wafers and silicon chips to designated locations.

Semiconductor Ceramic Heater

Semiconductor heaters have excellent thermal conductivity, high temperature resistance and electrical insulation. They can heat up quickly and evenly, and are widely used in semiconductor manufacturing, optoelectronic equipment and other scenarios.

Vacuum Wafer Ceramic Chuck

Vacuum wafer chuck is an important device for precision machining and semiconductor manufacturing, designed for fixing and handling silicon wafers or other thin materials. It can use the principle of vacuum adsorption to ensure that the wafer is stable and does not move during processing, testing or cleaning.

Semiconductor Equipment Parts

Many semiconductor devices use advanced ceramic products, such as ceramic insulating disks, ceramic insulating rings, thermistors, gas-sensitive ceramics, photosensitive ceramics, etc.

One-stop Semiconductor Ceramic Manufacturing Service

15+ Yılların Deneyimi. Yüksek Hassasiyet ve OEM Tasarımı. Profesyonel Ar-Ge Ekibi. Rekabetçi Fiyat.

What is the service life of your products?

Our semiconductor ceramic products have excellent durability and can work stably for a long time in high temperature, high pressure and corrosive environments, reducing your replacement costs.

How to choose materials?

According to different application scenarios, we recommend you to choose the right material:

- Aluminum nitride (AlN): It has excellent thermal conductivity (>170 W/m·K) and electrical insulation, and is suitable for high-power semiconductor devices.

- Aluminum oxide (Al₂O₃): It has good mechanical strength and corrosion resistance and is widely used in conventional electronic components.

- Silicon nitride (Si₃N₄): It has both high temperature stability and impact resistance, and is particularly suitable for key components in harsh environments.

Your customization capabilities

We support customization of various specifications and complex structures. Whether it is micron-level precision processing or the manufacturing of special-shaped parts, we can meet your requirements.