Seramik Isıtma Elemanı Tedarikçisi

Alümina, silisyum karbür, silisyum karbür ve diğer malzemelerden yapılmış yüksek kaliteli seramik ısıtma elemanları tedarik ediyoruz ve ürün kalitesini artırmak ve müşteri memnuniyetinizi karşılamak için çeşitlendirilmiş, yüksek kaliteli özelleştirme hizmetleri (logonuz dahil) ve çok rekabetçi toptan fiyatlar sağlıyoruz.

Çeşitlendirilmiş Seramik Boru Tedariği

GORGEOUS, geniş bir yelpazede seramik ısıtma elemanları sunan ileri seramik ürünleri üreticisidir.

Seramik ısıtma elemanları üretiminde uzmanlaşmış ve Ar-Ge'ye dayalı olarak, teknolojik yeniliklere bağlı kalarak, ürün geliştirme, üretim ve satışını entegre eden yüksek teknolojili bir kuruluştur.

Başlıca ürünlerimiz arasında MCH seramik ısıtma elemanları, yüksek sıcaklık alümina/silisyum nitrür seramik ateşleyiciler, su ısıtma seramik ısıtma elemanları ve küçük pil paketi ısıtma elemanları bulunmaktadır. Ayrıca, farklı müşteri ihtiyaçlarını karşılamak için özelleştirilmiş hizmetler de sunuyoruz.

Profesyonel bir Ar-Ge ekibimiz, gelişmiş ekipmanlarımız ve sıkı bir çevrimiçi üretim kalite kontrol sistemimiz bulunmaktadır. ISO9001:2015 kalite sistem sertifikası, TS16949 kalite sistem sertifikası, IATF 16949:2016 kalite sistem sertifikası ve ISO14001:2015 çevre yönetim sistemi standardı sertifikalarına sahibiz. Size en iyi ısıtma elemanı çözümlerini sunmaya kararlıyız.

Farklı Malzemelerden Seramik Isıtma Elemanları Tedarik Edin

Özelleştirme için çeşitli malzemeler mevcuttur

Müşterilerimize çeşitli özelleştirilmiş çözümler ve alümina, silisyum karbür, silisyum nitrür, alüminyum nitrür ve diğer yaygın seramik ısıtıcı malzemeleri gibi seçebilecekleri çeşitli malzemeler sunuyoruz.

Alüminyum Nitrür Isıtıcılar

Yarı iletken gofret ve LED'lerin ısıtılması gibi 1000°C'ye kadar yüksek sıcaklık uygulamaları için uygundur. Özel boyutlar ve güç değerleri mevcuttur. Fiyat teklifi için lütfen bizimle iletişime geçin.

Alümina Isıtıcılar

Otomotiv, gazyağı, gaz, su ısıtıcıları ve diğer kullanımlar için uygundur, sıcaklık 800-1000℃'ye ulaşabilir ve boyut ve güç özelleştirilebilir. Fiyat teklifi almak için lütfen bir talep gönderin.

Silisyum Nitrür Isıtıcılar

Yüksek mekanik mukavemet ve termal şok direncine sahip, boyut ve güç açısından özelleştirilebilir, otomotiv, yüksek sıcaklık endüstrileri ve daha fazlası için uygundur. Fiyat teklifi almak için bize ulaşın.

Silisyum Karbür Isıtıcılar

Endüstriyel fırınlar, ısıl işlem ve diğer uygulamalar için uygun olan bu ürünler, uzun kullanım ömrü ve özelleştirilebilir güç ve boyut seçenekleri sunar. Fiyat teklifi almak için gereksinimlerinizi belirtin.

Farklı Amaçlar İçin Seramik Isıtıcılar Tedarik Edin

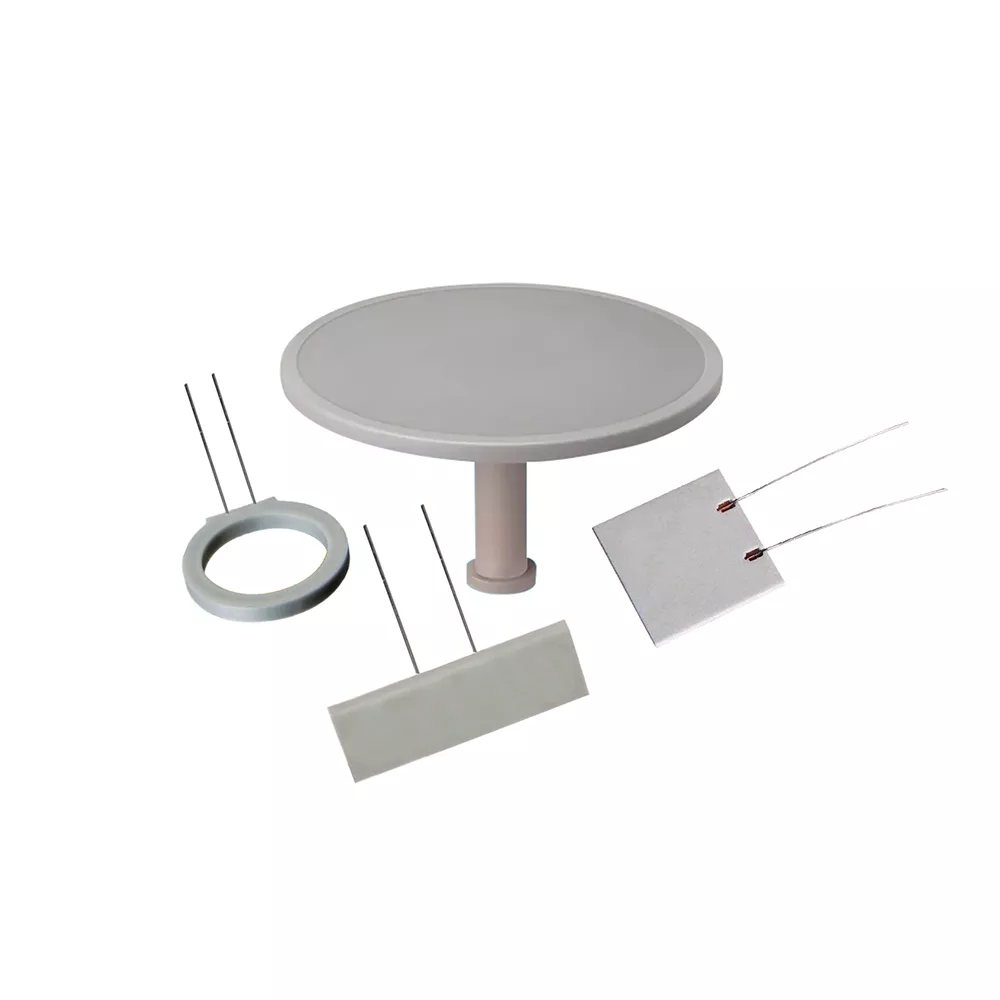

Lehimleme Demiri/Lehimleme İstasyonu için Seramik Isıtma Çekirdeği

Birincil malzeme 95% Al₂O₃ ve özelleştirilebilir.

MCH, seramik bir levha üzerine bir ısıtma tabakası basılarak ve sinterlenerek üretilen yeni bir çevre dostu ısıtma elemanıdır. 1650°C.

Isıtıcı yüzey sıcaklığı şu değerlere ulaşabilir: 800°C içinde 30 saniye.

Metal seramik ısıtıcılar mükemmel direnç sunar, sessizdir ve çeşitli ısıtma ayarlarına uyarlanabilir.

Ayrıca MCH zararlı madde içermez ve çevre dostudur.

Pil Paketi Isıtma Çekirdeği

Çeşitli ürünler sunuyoruz 3.7V Pille çalışan seramik ısıtıcılar. Kompakt boyutlarıyla popüler olan bu ısıtıcılar, ihtiyaç duyduğunuzda güvenilir ve dayanıklı bir ısıtma sistemi sunar.

Lütfen sipariş verirken aşağıdaki bilgileri sağlayın:

- Çalışma voltajı: 3.7V-7.4V

- Isıtıcı şekli: Seramik çubuk/tüp/bardak/halka vb.

- Özelleştirilebilir ısıtma performansı gereksinimleri (ısıtma süresi/çalışma sırasında termostat kullanılıp kullanılmayacağı)

- Çalışma ortamı (hava/su/herhangi bir yer)

- Isıtma alanı boyutları

- Isıtma elemanı ve destek malzemesi montaj yöntemi

- Cihazın çalışma sıcaklığı ve ısı dağılım yöntemi

- Isıtılmış nesne malzemesi

- Isıtma elemanı görev döngüsü, ısıtma ve soğutma sıklığı

- Isıtma elemanı maliyet bütçesi

- Detaylı çizimler veya örnekler çok yardımcı olur.

3D Yazıcılar için Seramik Isıtma Elemanları

GORGEOUS, 3D yazıcılar için seramik ısıtma elemanları üreten ve tedarik eden profesyonel bir firma olup, özelleştirilmiş hizmetler sunmaktadır.

- Ana Malzeme: Alümina Seramik

- Uygulama: 3D Yazıcı Sıcak Uçları

- Seramik Isıtma Boru Şekilleri: Boru, Bardak, Halka, Tabak, vb.

- Çalışma Voltajı: 12V veya 24V

- Güç: 40W-60W-80W

- Seramik Isıtma Borusu Boyutları: Standart veya Özel

- Çalışma Sıcaklığı: 300-500°C

- Isıtma Hızı (Sadece Isıtma Elemanı): 300°C'ye 15 saniye

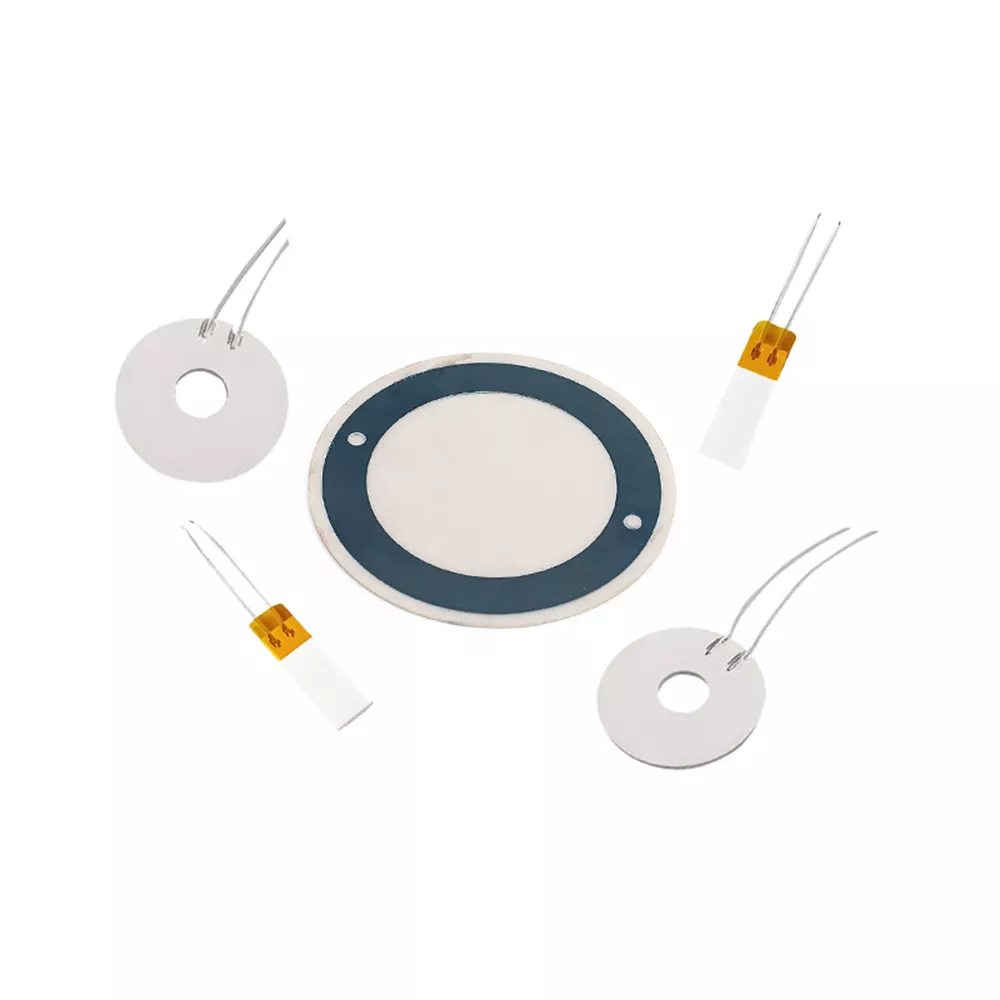

Tankless Su Isıtıcı Elemanı

Bu ürün serisi, akıllı tuvaletler gibi anında su ısıtıcılarında yaygın olarak kullanılmaktadır. Kompakt yapıları, yüksek güçleri ve hızlı ısıtma hızları sayesinde seramik ısıtıcılar, PTC/metal ısıtıcılara göre daha fazla güvenilirlik sunar.

Seramik ısıtma elemanları, alüminyum oksit yeşil levhalara doğrudan devre baskısı yapılarak üretilen yeni bir ısıtma elemanı türüdür. Bu elemanlar bir dizi özel işlemden geçirilir ve ardından yaklaşık 1600°C'de eş zamanlı olarak pişirilir. Ürün sıcaklığı sadece 30 saniyede 800°C'ye ulaşabilir.

Kızılötesi Seramik Isıtıcı

Fırınlar için seramik borular Genellikle endüstriyel fırınlarda ve ısıtma ekipmanlarında kullanılır. En yaygın türü alümina fırın borularıdır. Alümina, mükemmel yüksek sıcaklık direncine (1600℃'ye kadar dayanabilir), korozyon direncine ve mekanik özelliklere sahiptir. Isıl işlem, malzeme sinterleme, toz metalurjisi vb. gibi yüksek sıcaklık ve zorlu çalışma koşullarında istikrarlı bir şekilde çalışabilir ve alümina diğer seramik malzemelerden daha ucuzdur.

GORGEOUS, müşterilerinin yüksek sıcaklık fırın uygulamaları için en iyi çözümü sağlayarak, müşteri gereksinimlerine göre çeşitli ebatlarda ve bağlantı noktası yapılarında seramik tüpleri özelleştirebilir.

Oksijen Sensörü Isıtma Elemanı

Oksijen sensörleri, aracın egzoz akışındaki oksijen miktarını izler ve seramik sensör ısıtıcıları O2 sensörlerinde önemli bir rol oynar.

Alüminyum oksitten yapılan ve zirkonyum oksit seramik tüpe yerleştirilen geleneksel oksijen sensörleriyle karşılaştırıldığında, bu sensörlerin etkinleştirilmesi genellikle 20 saniye sürer.

GORGEOUS, alüminyum oksit ve zirkonyum oksiti birleştiren yeni bir lamine düzlemsel oksijen sensörü kullanır. Isıtma elemanı, sensör elemanının zirkonyum oksit alt tabakasına yerleştirilmiştir. Isıtma alt tabakası olarak alüminyum oksit kullanılması, zirkonyum oksidin düşük ısıl iletkenliğini ele alırken optimum ısıtma sağlar. Yeni lamine düzlemsel oksijen sensörü, soğuk çalıştırmadan sonra 10 saniye içinde etkinleşebilir.

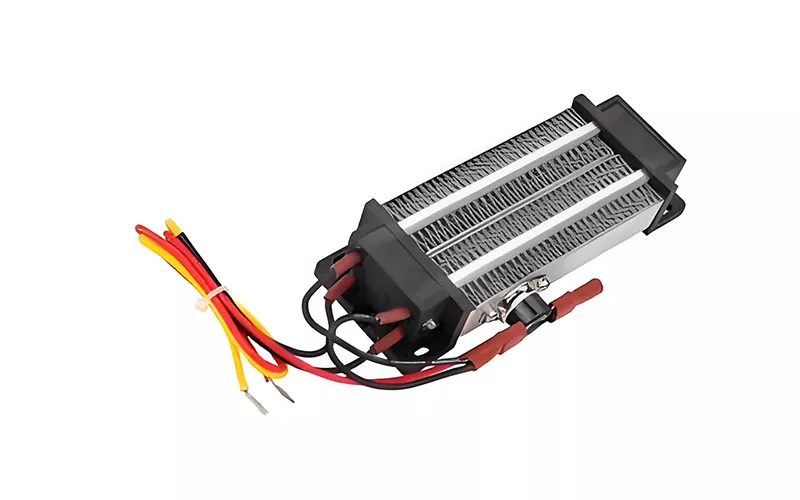

PTC Seramik Isıtıcı

Hızlı ısıtma, otomatik sıcaklık düzenleme ve aşırı ısınmayı önleme için 10.000 saatin üzerinde kullanım ömrüne sahip PTC seramik ısıtma teknolojisini kullanıyoruz. İster ev aletleri, ister endüstriyel ekipman veya otomotiv ısıtması için kullanın, PTC seramik ısıtıcılar istikrarlı, güvenli ve enerji tasarruflu bir ısıtma deneyimi sunar.

GORGEOUS, farklı ihtiyaçlarınızı karşılamak için çeşitli özel boyutlar, voltajlar ve güç dereceleri sunar.

Neden GORGEOUS'un Özel Seramik Isıtıcılarını Seçmelisiniz?

GORGEOUS fabrikamızın seramik üretiminde 15 yıllık deneyimi bulunmaktadır, bu da müşterilerimize daha kaliteli seramik ısıtıcılar sağlayabileceğimiz anlamına gelir.

SSS

Seramik ısıtıcı elemanları güvenli midir?

Seramik ısıtıcı elemanlarımızı tasarlarken ve üretirken güvenliği en üst düzeyde dikkate alıyoruz. Profesyoneller tarafından tasarlanıp üretildikten sonra, titiz test ve sertifikasyon süreçlerinden geçmiştir. Aşırı sıcaklıkların neden olduğu yangın sorunlarını veya elektrik kaçağı ve elektrik çarpması gibi kazaları önlemek için elimizden gelenin en iyisini yapıyoruz.

Seramik ısıtıcı elemanı özelleştirilebilir mi?

Seramik ısıtıcı elemanı özelleştirilebilir. Özel ısıtma ihtiyaçlarınız varsa, lütfen uzmanlarımızla iletişime geçin. Özel ihtiyaçlarınızı karşılayacak en uygun özelleştirilmiş çözümü sağlayabiliriz.

Seramik ısıtıcı elemanı güçlü asit veya alkalilerden kaynaklanan korozyona karşı dayanıklı mıdır?

Seramik ısıtıcılar özellikle mükemmel korozyon direncine sahiptir ve asitler, alkaliler ve aşındırıcı gazlar gibi kimyasalların neden olduğu korozyona karşı direnç gösterebilirler.

Seramik ısıtıcı elemanının avantajları veya dezavantajları nelerdir?

Seramik ısıtıcı elemanının avantajları şunlardır: yüksek sıcaklık direnci, korozyon direnci, üstün ısı iletkenliği, iyi yalıtım ve toksik olmayan ve çevre dostu bir malzemedir.

Ancak maliyetinin yüksek olması, kırılganlığının nispeten yüksek olması, dış darbelerle kolay hasar görmesi, metale göre ısıtma veriminin daha yavaş olması gibi bazı dezavantajları da vardır.

Seramik ısıtıcı elemanının stabilitesi nasıldır?

Seramik ısıtıcı elemanlar yüksek sıcaklık ortamlarında iyi bir stabiliteye sahiptir, yumuşamaya, deformasyona veya termal şok çatlaklarına eğilimli değildir ve istikrarlı ısıtma etkilerini korurlar.

Seramik ısıtıcı elemanı tıbbi veya gıda sektöründe kullanılabilir mi?

Seramik ısıtıcı eleman malzemeleri toksik değildir, kokusuzdur ve koku üretmez. İyi hijyenik özelliklere sahiptir ve gıda ısıtma ve tıbbi ekipman gibi uygulamalar için uygundur.