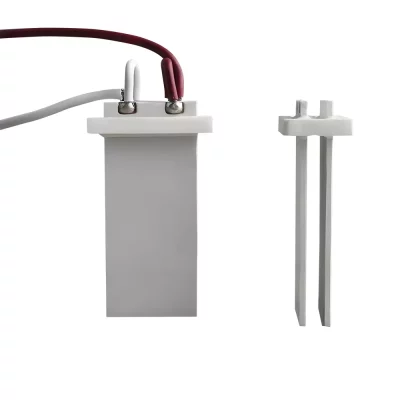

GORGEOUS CERAMICS (GGS) ceramic heating rods for dental floss machines are manufactured using a lamination and vacuum processing process. The metal conductor and ceramic substrate are simultaneously co-fired at approximately 1650°C, forming a dense and stable monolithic structure.

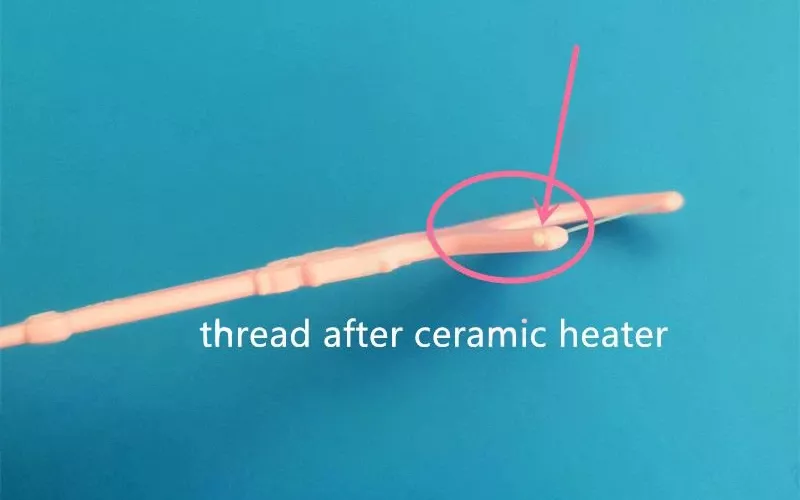

Furthermore, after sintering, processes such as wire bonding are performed to ultimately create a reliable medium-to-low temperature ceramic heating element.

This GORGEOUS CERAMICS (GGS) product features rapid heating, high safety, long lifespan, and superior insulation, making it ideal for use in dental floss machines (oral irrigators) and similar products.

Ceramic Heating Rod for Water Flossers Product Information

재료 구성:

- Heater Body: 95% white Al2O3 ceramic

- Lead Wire: 0.5mm nickel wire or nickel-copper wire

- Shell: Teflon

- Heating Material: Tungsten

|

ltem |

Specification |

|

Operating Voltage |

20V-24V |

|

Heating Resistance |

4.6Ω |

|

Heater Body Size |

Length 70 mm×Diameter 4.0 mm |

|

Heating Zone Length |

9 mm |

|

Nickel Lead Wire Length |

80 mm (custom lengths available) |

|

Lead Wire Insulation |

White PTFE / No insulation / Other options available |

Advantages of Ceramic Heating Rods

- Rapid heating: Reaches 300℃ in 10 seconds and 500-700℃ in 20 seconds, meeting rapid heating needs.

- High thermal efficiency: Over 90%, significantly reducing energy consumption.

- Environmentally friendly heating process: Does not pollute the environment.

- Uniform heating: No localized heating or open flame risk.

- Highly corrosion-resistant: Ideal for the moist oral environment.

- Long lifespan: Minimal performance degradation; power output decreases by only 5% over long-term use, ensuring stable output.

Application of Ceramic Heating Elements in Dental Floss Machines

Dental floss picks, textiles, dental floss pick equipment, toothpick machine, toothpick machine, dental floss equipment