소개

Ceramic insulators are one of the best at resisting the flow of electricity. Due to this, many engineers refer to them as excellent electrical insulators. In the following paragraphs, we’ll explore the answers to various questions such as: why is ceramic a good insulator? What are the properties, types, and uses that make them outstanding? Let’s dive in!

What is a Ceramic Insulator?

Insulators are special objects made from materials that are highly resistant to electric flow. Materials such as ceramics, plastic, glass, porcelain, etc.

Fig 1. Insulator Materials

Therefore, a ceramic insulator is an insulator material made from ceramics. They exhibit a resistance that completely prevents electricity from travelling through them. The material used in its production could be advanced ceramics (Boron Nitride) or porous clay (white, brown, or red).

Generally, ceramics tend to be natural electrical insulators due to their excellent thermal, electrical, and mechanical properties. They do the direct opposite of electrical conduction. Little wonder, Industries prefer to use them in producing high-grade insulators, advanced hermetic sealings, and electronic components.

Ceramic insulators are known to possess high dielectric strength and provide a bridge between electrical components. They are specifically made to prevent power loss, arcing, and withstand high voltages even in unfavorable conditions. This quality is mainly because of their tightly held valence electrons. Their thermal shock resistance and low thermal conductivity ensures efficient energy-saving and safety of electrical systems.

Ceramic electrical insulators play a vital role in overhead power transmission lines. Electric poles, before now, used powerline ceramic insulators. Even now, their importance hasn’t diminished at all. Porcelain (porcelain insulators) is the mainstream type of ceramic insulator used by most industries now.

Interestingly, they protect you from getting shocked by an electric current. How? It’s simple - because they’re excellent electrical insulators. Meaning, you can use them as shields/objects to safely transmit/handle electricity without getting harmed. Good examples are powerline ceramic insulators, your changeover switch at home, alumina based insulators, porcelain insulators, steatite, ceramic fibers/wool, etc.

High voltage lines ranging from 11kV to 400kV mostly make use of ceramic electrical insulators. They have a solid design that makes them light, chemically stable, have good thermal conductivity and low dielectric loss. Therefore, you can trust them to maintain effective performance despite environmental factors like UV rays, wind or pollution. Recently, the ceramic insulators (12-18 suspension discs) I designed for a certain substation withstood 345Kilovolts without breaking down.

Although, you will most likely get better electrical insulation from a ceramic electrical insulator with high ceramic density. The higher the density (porousity) the better the ceramic electrical insulator. Little wonder, most electrical engineers carefully weigh their options when it comes to choosing ceramic electrical insulators for high voltage transmission lines.

The table below compares some of the widely used ceramic electrical insulators and their ceramic densities.

|

Silicon carbide based ceramic insulators |

3.2g/cm³ |

|

Porcelain insulators |

2.45g/cm³ |

|

Alumina based ceramic insulators |

3.94g/cm³ |

|

Boron nitride based ceramic insulators (C-bn) |

3.45g/cm³ |

|

Glass insulators |

2.4g/cm³ |

|

Aluminum nitride ceramic insulators |

3.32g/cm³ |

Properties of Ceramic Insulators

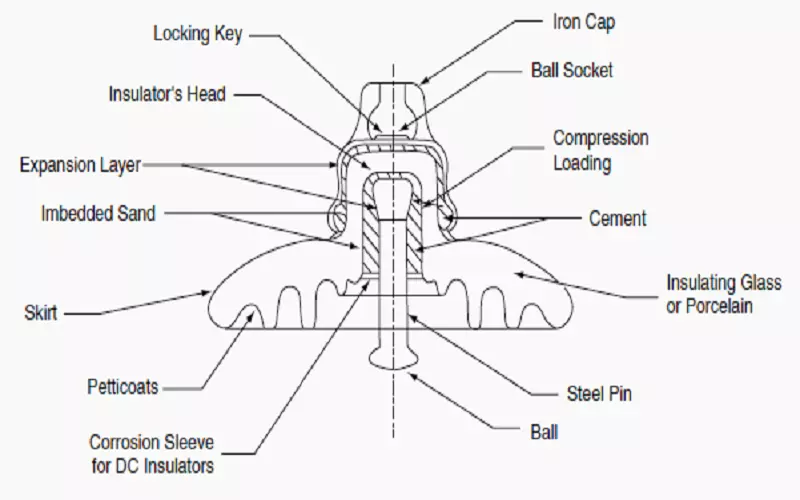

Fig 2. Structure of Ceramic Insulator

Ceramic insulators have many amazing properties that set them apart. Some of them are:

-

Excellence at resisting thermal shocks and electric current up to 100 Ohms per cm.

-

Outstanding waterproof performance.

-

Excellent hardness and durability.

-

Low coefficient of thermal expansion that rises slightly with increasing temperature.

-

They possess a glazed smooth surface that prevents dust particles and residues from gathering.

-

Highly resistant to chemicals, oils, alkalis, gas fumes, and rusting (oxidation).

-

They’re non-inflammable.

-

Ceramic insulator price is affordable compared to insulators. Averaging around $8-15/kg (Source: Statista 2025).

Let’s compare some of the key properties of ceramic insulators with other types of insulators like plastic and glass insulators.

|

재료 특성 |

Ceramic /porcelain Insulators |

Glass Insulators |

Plastic Insulators |

|

Dielectric strength (kV/mm) |

4 - 17 |

9 -30 |

16 - 200 |

|

Thermal conductivity (W/m.K) |

1 - 250 |

0.03 - 1.4 |

0.1 - 0.5 |

|

Temperature resistance (°C) |

up to 2,100 |

up to 1000 |

up to 398 |

|

Flexural strength (Mpa) |

70 - 150 |

200 - 300 |

30 - 150 |

|

Tensile strength (Mpa) |

50 - 100 |

150 - 200 |

20 - 100 |

|

Compressive strength (Mpa) |

500 - 1000 |

800 - 1000 |

50 - 250 |

|

밀도(g/cm³) |

2.4 - 6 |

2.4 - 2.6 |

0.9 - 1.5 |

Types of Ceramic Insulators

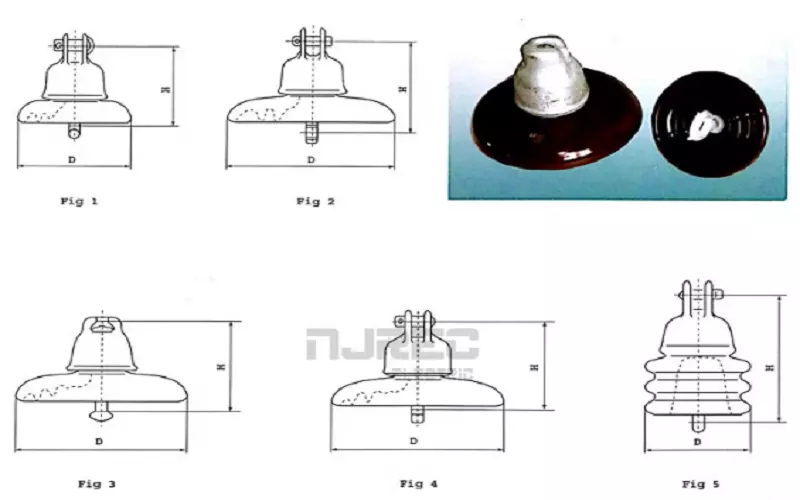

There are several types of ceramic insulators available for you to choose from, depending on your application and budget. Here, we’ll look at the five major types of ceramic insulators.

Fig 3. Types of Insulators

-

Pin-Type Ceramic Insulators:

Pin-type ceramic insulators are for high voltage and low voltage power transmissions. When mounted on a pin or crossarms on a pole, they can withstand voltages up to 33kV. Due to this, engineers mostly use them to support and insulate conductors in transmission and distribution lines.

They’re well-built to deliver effective insulation in utility networks. Wiring systems for modern buildings also benefit from their operation. Pin type ceramic insulator price is also very affordable, little surprise it’s one of the most used insulators.

-

Suspension-Type Ceramic Insulators:

This is one of the most common types of ceramic insulators. You can also call them ceramic insulators for high voltage. They have the shape of a porcelain disc, connected in series to form a stringed system.

These ceramic insulators easily suspend power conductors from the cross-arms of utility poles, preventing sagging and isolating them electrically.

Their primary role is to support and insulate the conductors in overhead high-voltage power transmission lines. They are easy to maintain and replace due to their simple design.

-

Strain Ceramic Insulators:

Strain-type insulators are usually used at sharp turns or dead ends in distribution lines. They’re specially designed to bear the continuous pull and tensile force exerted by conductors in overhead transmission lines. Hence, they are also called mechanical tension ceramic insulators.

-

Shackle Ceramic Insulators:

Shackle-type insulators are ceramic electrical insulators for low-voltage distribution lines. They are suitable for applications that demand moderate mechanical load. You can either mount them vertically or horizontally. They also help to change the direction of the conductor.

-

Post Ceramic Insulators:

Post ceramic electrical insulators, also known as spool insulators, are usually mounted on cross arms or brackets. They are used as compact components to support electrical wiring on transformers, substations, or utility poles.

-

Steatite Insulators:

Steatite insulators are very special types of ceramic insulators with high electrical resistance. They are specially made to handle low voltages, making them one of the most common types of ceramic insulators. Electronic appliances used in the home like radio and television sets all use steatite insulators. One major reason for this is because Steatite ceramic insulator price is very affordable, compared to other insulators.

-

Powerline Insulators:

Powerline ceramic insulators are cylindrical shaped insulators attached to powerlines (high voltage transmission lines). These power lines need a ceramic insulator for general safety. How? - It ensures the air gap is maintained between the bare conductor, ground and the energized poles. They separate the powerline from ground electrically and physically. Electricity generating and distribution companies use these types of ceramic insulators to prevent flashovers and electrical shorts. Powerline ceramic insulator price is cheaper than plastic insulators and will not break down due to sun damage.

Uses of Ceramic Insulators

Fig 4. A ceramic Insulator Design

The uses of ceramic insulators are very numerous. Their usefulness spans across homes/residential areas, industries, offices, and high-stress environments. Alright, let’s see some of the use cases of ceramic insulators:

-

They’re a major component of transformers. This is due to their exceptional ability to perform well in high-temperature conditions.

-

You can use them as wire supports on utility poles and telecommunication masts.

-

A ceramic insulator for heaters helps in supporting heating elements.

-

As tension insulators, they can help you reduce wear and tear while also preserving circuit integrity.

-

They’re used in railway electrification systems and overhead power distribution to ensure safety.

-

Replacing metal parts with a ceramic insulator for heater elements is a major advancement in technology today.

-

A Ceramic insulator for heater systems can help you warm up your room, office and even bathrooms.

-

Most household appliances use ceramic insulators. Examples are water heaters, changeover switches, Television sets, refrigerators, etc.

-

You can use ceramic insulators for heaters, reliable heat sinks, furnaces, and industrial ovens.

-

Ceramic insulators are useful in the production of strong and efficient spark plugs and ceramic feedthroughs. These spark plugs are very useful for automobiles and engines.

-

The autoclaves and water-bath in most hospitals use a ceramic insulator for heater systems and sterilization.

-

Production of sleeve washers that prevent galvanic corrosion and electrical current bypass at fastener junctions.

-

You can tie flexible high-voltage wire around utility poles with the help of ceramic insulators.

-

In medicine, ceramic insulators help to boost the efficiency of X-ray technology.

-

You can also use them to make efficient semiconductor materials.

-

Ceramic insulators for heater elements are your best bet when considering safety.

What are the Benefits of Using Ceramic Insulators?

Fig 5. Ceramic Insulator Application

Ceramic insulators have a lot of amazing properties, and you stand to gain so many benefits from using them. Some of these benefits include:

-

They give you excellent performances and longer service years (durability).

-

High strength means they can withstand high temperatures and heated conditions without breaking down.

-

The majority of them are water-resistant.

-

They are very easy to maintain compared to other types of Insulators.

-

There are no allergy concerns with ceramics.

-

Powerline ceramic insulators have a lighter weight that are beneficial in transformers.

-

They don’t get rust easily compared to other insulators.

-

They have a higher dielectric strength than other insulator materials.

-

Sun damage doesn’t cause them to break down like plastic insulator materials.

-

They have higher insulating properties than any other type of insulator out there.

-

They ensure maximum safety and can help you prevent electrical hazards. For example, electrical arcing, electromagnetic interference, electrical shorts, power surges, or fire risks.

-

세라믹 insulator price is a bit expensive compared to other insulators, but they’re worth it in the long run. How? Let’s say you buy a porcelain insulator or a high voltage ceramic insulator that averages $8-15/kg (Source: Statista Q2 2025); It’ll take you a significantly lesser amount to maintain it and as a result, last longer. Whereas, you may buy a glass or plastic insulator at a slightly reduced price and end up replacing it thrice before you even replace a ceramic insulator. That’s how durable and reliable a ceramic insulator can be.

Even with these great benefits, it’s important you take note of ceramic insulator price fluctuation factors. The major factors include:

-

Cost of raw materials like alumina, SiC, etc., (accounted for 60% price fluctuations in 2025).

-

Global prices of commodities.

-

Government policies and regulations.

-

Market competition.

-

Advancements in technology.

-

Rising cost of energy.

Leading Manufacturers of Ceramic Insulators

The importance of ceramic insulator materials to the modern economy and infrastructure cannot be overlooked. Therefore, several top manufacturers in the United States, China, Canada, and many other countries invest in them.

If you’re looking to purchase, here are some of the leading suppliers of these ceramic insulators:

-

GGSCERAMICS, China.

-

Shanghai Metal Corporation, China.

-

Siemens AG, Germany.

-

KYOCERA Fine Ceramics, Japan.

-

NGK Insulators Ltd., Japan.

-

General Electric, USA

-

PPC Insulators, Austria.

-

Aditya Birla Insulators, India

-

C-Mac International, LLC

-

Aremco Products, Inc.

-

LSP Industrial Ceramics, South Carolina.

The global market for ceramic insulators is experiencing rapid growth. Although glass insulators still account for 15% of the market share in 2025 according to Nexans report. Latest market research placed the current market size at an estimated $3.5 billion in 2024. The CAGR as of now stands at 4.8%, implying that we could see a market value of $5.2 billion by 2033. Consequently ceramic insulator prices may increase in response to this.

자주 묻는 질문

Are ceramic insulators waterproof?

Yes, especially if you use ceramic fiber waterproof blankets during installation to keep the material dry.

Can electricity penetrate ceramic insulators?

No, hence they’re called electric insulators. Ceramics effectively resist the flow of electric current.

Why is ceramic a good insulator?

Ceramics are good electrical insulators due to their tightly packed valence electrons and low thermal expansion.

Can a ceramic insulator fail?

Yes, it can, and one of the most common failures is contamination failure. Resulting from surface discharge caused by dust, salt, or dirt accumulation.

결론

Ceramic insulators have now become a popular choice in many industries and homes due to their amazing properties. Their excellent performances while under electrical and mechanical stress put them way ahead of other insulators. They’re easy to use in any application and also very affordable. Order from us now at GGSCeramics to get some top-quality ceramic insulators. Don’t wait!